Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380V or Customized

-

Power:

-

12KW

-

Dimension(L*W*H):

-

1500*710*1920mm

-

Weight:

-

110 KG

-

Output product name:

-

popcorn

-

Heating Method:

-

Electromagnetic Heating

-

Kettle Shape:

-

Spherical

-

Kettle Size:

-

48 oz

-

Stirring Method:

-

Planetary Stirring

-

Popcorn Type:

-

Butterfly or Mushroom

-

Automaticity:

-

Semi-automatic

-

Material:

-

Stainless Steel

Quick Details

-

Marketing Type:

-

Hot Product 2022

-

Core Components:

-

Electromagnetic Kettle

-

Brand Name:

-

TASN

-

Place of Origin:

-

Shanghai, China

-

Voltage:

-

380V or Customized

-

Power:

-

12KW

-

Dimension(L*W*H):

-

1500*710*1920mm

-

Weight:

-

110 KG

-

Output product name:

-

popcorn

-

Heating Method:

-

Electromagnetic Heating

-

Kettle Shape:

-

Spherical

-

Kettle Size:

-

48 oz

-

Stirring Method:

-

Planetary Stirring

-

Popcorn Type:

-

Butterfly or Mushroom

-

Automaticity:

-

Semi-automatic

-

Material:

-

Stainless Steel

Product Innovation Features

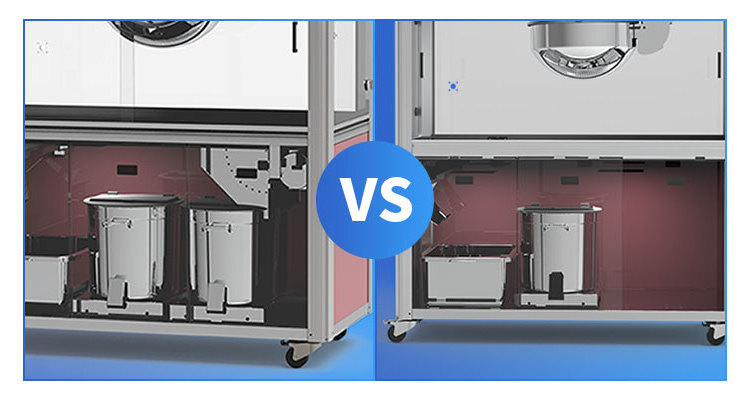

Innovative feature No. 6: Dual-core Oil Circuit

Solving Pain Points 09:

Oil circuit failure

No syrup system popcorn machine if the coconut oil system failure then the popcorn machine can only be shut down, especially during the peak season of large festivals when the failure to the cinema is bound to cause huge losses, while the syrup system of this equipment and coconut oil system can be used interchangeably, you can transfer the coconut oil barrel to the position of the syrup, two minutes to resume the production of popcorn for the cinema to avoid major losses.

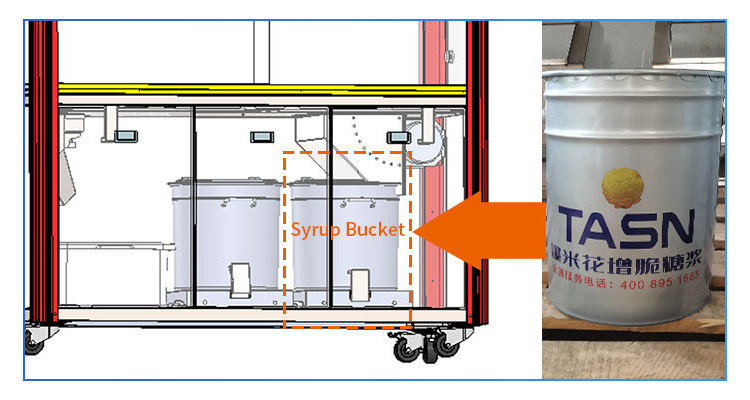

Innovative feature No. 5: Syrup Increases the Crisp

Solving Pain Points 08:

Sweet and Crisp Contradictions

The low crispness and high sweetness of popcorn has been a major hazard affecting sales, the cinema in order to increase the crispness can only increase the ratio of powdered sugar, therefore increasing the cost of the same time the sweetness is bound to increase, causing consumers to fear sugar and lead to a decline in sales, which has led to a contradiction. The moisture-proof properties of the syrup not only double the crispness of the popcorn can also keep the crisp time significantly longer, but the sweetness of the popcorn does not increase. The use of syrup can also reduce the amount of powdered sugar by half, which is used to replace the cost of syrup so that the total cost of popcorn does not increase, so syrup becomes the perfect solution for popcorn to solve the contradiction of sweetness and crispness and increase sales.

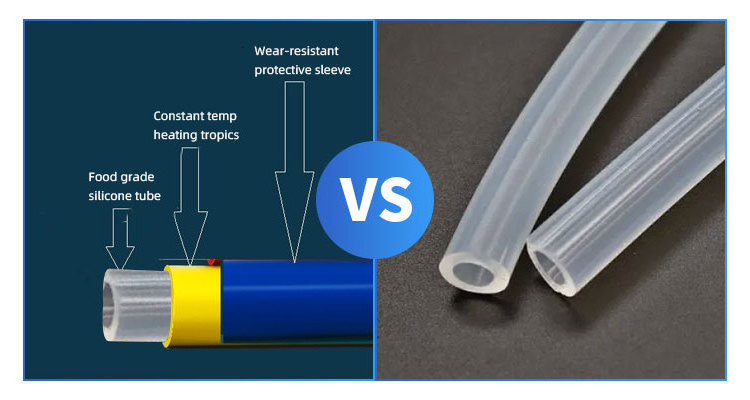

Innovative feature No. 4: Oil Tube Anti-blocking

Solving Pain Points 07:

Oil Tube Blockage

It eliminates the problem of the stored oil in the oil tube solidifying at low temperatures and blocking the oil tube and preventing it from being pumped, which is a very high incidence phenomenon. Our innovative oil tube can completely melt the solid oil in the tube within 15 minutes and can also automatically maintain a constant temperature, which also keeps the oil tube open in real time.

Innovative feature No. 3: Electromagnetic Heating

Solving Pain Points 04:

Too Slow to Preheat

Compared to resistance heating, which eliminates the ten-minute wait for the pot preheating before bursting, electromagnetic heating is ready to use.

Solving Pain Points 05:

Residual Heat Paste Pot

The resistance heating method is used when the pot reaches a temperature where the pot will continue to be heated by the heat generator even if the power is cut off, thus aggravating the paste pot. However, the magnetic field disappears immediately after electromagnetic heating has stopped supplying power and the popcorn is no longer heated, thus avoiding residual heat paste the pot .

Solving Pain Points 06:

Production Is Too Slow

Thanks to the rapid heating characteristics of electromagnetic heating, it solves the pain point that users cannot quickly make more popcorn to satisfy sales during peak hours.

Innovative feature No. 2:

Scraping Pot to Prevent Paste

Solving Pain Points 02:

Cumulative Paste Pot

The traditional stirring method of popcorn machine will appear the more times it is made, the more serious the situation of paste pot, frequent washing of the pot brings a lot of trouble and loss to the user. Our stirring method combined with the spherical pot system for popcorn production completely eliminates the phenomenon of paste pot, and the popcorn taste more pure.

Solving Pain Points 03:

Consumables for Washing Pots

Our stirring method of scraping pot allows you to clean the pan without the need to add special washing powder during the washing process.

Our stirring method of scraping pot allows you to clean the pan without the need to add special washing powder during the washing process.

Innovative feature No. 1:

One-click Production

Solving Pain Points 01:

Production of Cumbersome

non-the company's popcorn machine to make popcorn in addition to adding ingredients, at least several buttons need to be operated "① add ingredients → ②oil injection → ③ heating → ④stirring → ⑤ off heating → ⑥ off stirring → ⑦ turn the pot", the machine's [one-click production] function is a fusion of seven button actions into only one start button, thus solving a series of pain points such as staff training, cumbersome processes, peak periods occupy labor.

Product Paramenters

|

Model

|

Voltage

|

Power

|

Dimension(L*W*H)

|

Weight

|

Specification

|

Capacity

|

|

C32ZC

|

220V

|

6KW

|

1500*710*1920 mm

|

90kg

|

32OZ

|

15~20kg/h

|

|

C36ZC

|

380V

|

8KW

|

1500*710*1920 mm

|

100kg

|

36OZ

|

20~25kg/h

|

|

C48ZC

|

380V

|

12KW

|

1500*710*1920 mm

|

110kg

|

48OZ

|

25~30kg/h

|

|

C52ZC

|

380V

|

15KW

|

1500*710*1920 mm

|

120kg

|

52OZ

|

30~35kg/h

|

Newly Upgraded Cinema Popcorn Machine

Click the Picture to View

Company Strength

Contact Us

Hot Searches