- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Machine Size

-

Weight (T):

-

3 T

-

Motor Power (kw):

-

7.5 kw

-

Power Source:

-

Hydraulic

-

Product name:

-

Shovel Making Machine

-

Color:

-

optional Kitchen Sink Making Machine

-

Application:

-

Metal Forming

-

Type:

-

Four Columns

-

Function:

-

Punching Ang Press

-

Material:

-

Steel Material

-

PUMP:

-

GEAR PUMP

-

COLUMNS:

-

ALLOY STEEL AND

-

MOTOR:

-

SERVO MOTOR

Quick Details

-

Machine Type:

-

Double Column Hydraulic Press

-

Ejector Force (kN):

-

3150

-

Return Force (kN):

-

300 kN

-

Place of Origin:

-

Jiangsu, China

-

Voltage:

-

380V

-

Dimension(L*W*H):

-

Machine Size

-

Weight (T):

-

3 T

-

Motor Power (kw):

-

7.5 kw

-

Power Source:

-

Hydraulic

-

Product name:

-

Shovel Making Machine

-

Color:

-

optional Kitchen Sink Making Machine

-

Application:

-

Metal Forming

-

Type:

-

Four Columns

-

Function:

-

Punching Ang Press

-

Material:

-

Steel Material

-

PUMP:

-

GEAR PUMP

-

COLUMNS:

-

ALLOY STEEL AND

-

MOTOR:

-

SERVO MOTOR

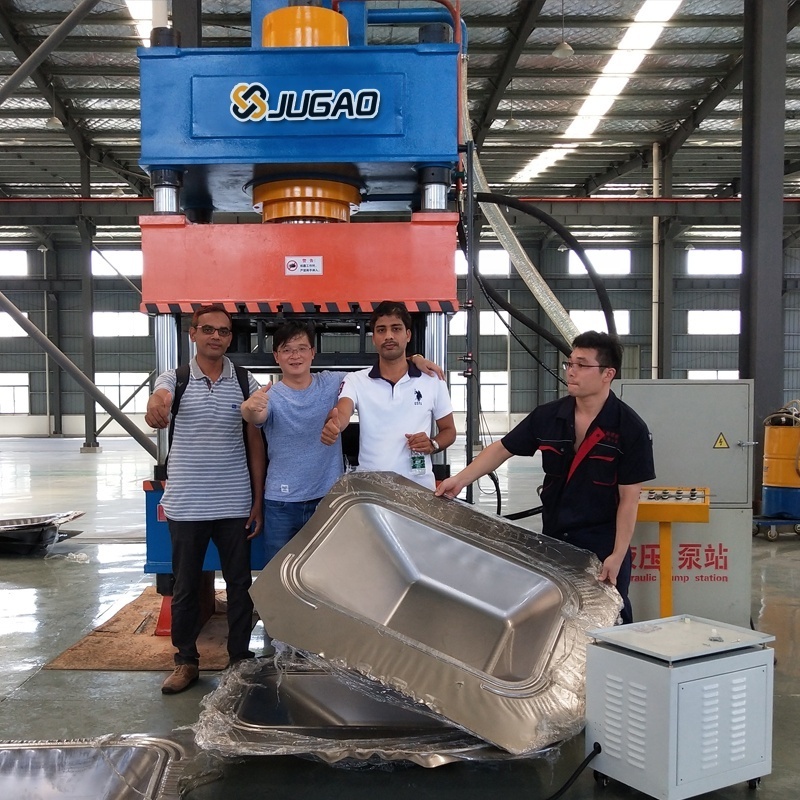

Metal Stamping Sink Pot stainless steel Shovel deep drawing Embossing Making Machine Hydraulic Press Machine

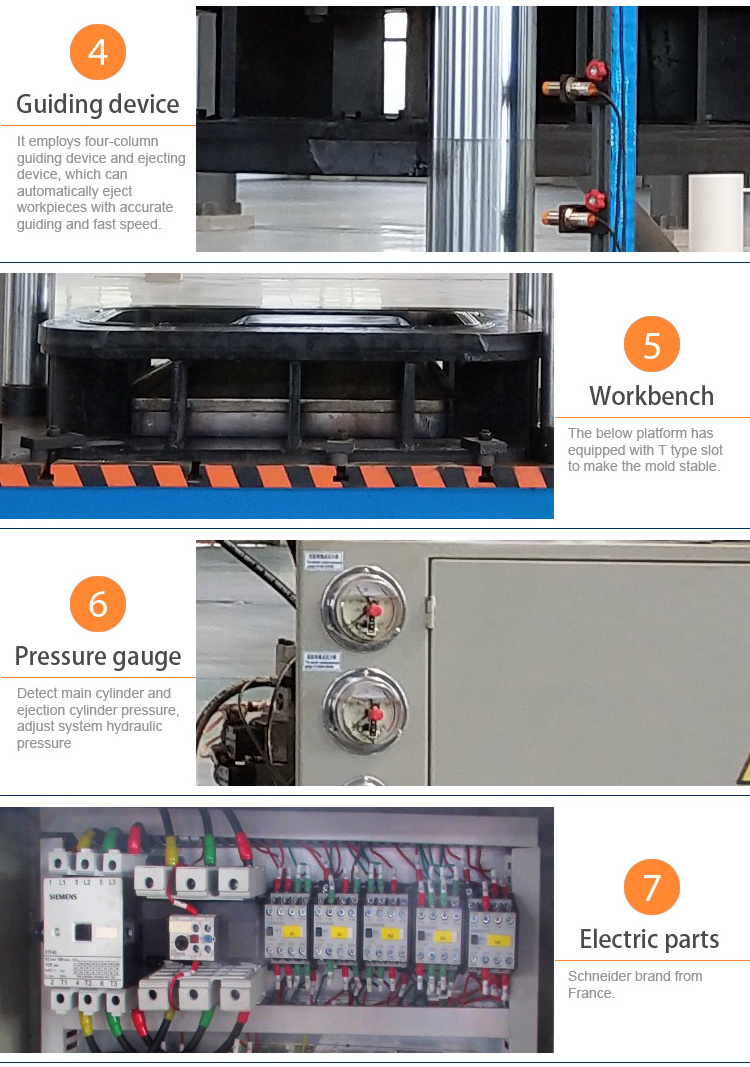

Functions

This equipment is a special stretching machine for the formation of small trolleys. It is used for the stretch forming of small trolleys. This equipment is mainly used for the production of large-scale stamping parts, which can be used for stretching, bending and flanging of metal sheets. Forming, blanking and other processes, also suitable for the correction, press-fit, press molding of powder products and abrasive products, and plastic products, compression molding of insulating materials. And has a low noise punching buffer function. Can meet the needs of mass production.

Technical Performance

1. Low energy consumption, high speed, low noise, high efficiency;

2. Slider divide speed into two segments to contorl: empty loading fast, slowly close mold, stretch;

3. Activity crossbeam has safety limiter in both up and down directions;

4. Equipped with photoelectric protection device, could guarantee the safety of the operation;

5. With the function of automatic and manual, it's convertible;

6. Two operation model, viz. pressure regulation and stroke regulation which can beselected through operational panel, and has the character of pressure-keeping and time-delaying.

Application

1. Auto parts, brake pads, fuel tanks, chassis, bumpers;

2. Household appliances: washing machines, rice cookers, televisions, refrigerators, air conditioners and other parts;

3. Kitchen appliances: washing tanks, pots, stainless steel cutlery, and other various containers;

4. Others: tractors, motorcycles, aviation, and aerospace .

Parameter

|

Item YJG-32 |

Nominal Force (KN) |

Ejecting force (KN) |

Max. working pressure (Mpa) |

Ram stroke (MM) |

Ejecting stroke (MM) |

Max open high (MM) |

Slider speed (MM/S) |

Working table size(MM) |

Dimensions (MM) |

|||

|

No-load working |

pressing |

return |

FB |

LR |

||||||||

|

40TON |

400 |

120 |

25 |

450 |

150 |

700 |

20 |

14 |

45 |

500 |

460 |

2000x1300x2600 |

|

63TON |

630 |

190 |

25 |

500 |

200 |

750 |

20 |

14 |

120 |

580 |

500 |

2400x1400x3100 |

|

100TON |

1000 |

190 |

25 |

600 |

220 |

880 |

22 |

14 |

47 |

720 |

580 |

2500x1500x2950 |

|

100BTON |

1000 |

190 |

25 |

600 |

200 |

880 |

120 |

14 |

120 |

720 |

580 |

2500x1500x2950 |

|

160TON |

1600 |

400 |

25 |

700 |

200 |

900 |

100 |

12 |

70 |

680 |

620 |

2700x1700x3400 |

|

160BTON |

1600 |

400 |

25 |

700 |

200 |

1000 |

100 |

12 |

70 |

1000 |

800 |

2800z1700x3400 |

|

200TON |

2000 |

400 |

25 |

700 |

250 |

1100 |

100 |

8 |

52 |

1000 |

900 |

3100x1800x3500 |

|

315TON |

3150 |

630 |

25 |

800 |

300 |

1250 |

100 |

8 |

60 |

1260 |

1200 |

3235x2060x4295 |

|

400TON |

4000 |

630 |

25 |

800 |

300 |

1250 |

100 |

7 |

45 |

1240 |

1200 |

3235x2200x4500 |

|

500TON |

5000 |

1000 |

25 |

900 |

350 |

1500 |

100 |

5 |

70 |

1400 |

1400 |

4060x3520x4995 |

|

500CTON |

5000 |

1000 |

25 |

900 |

350 |

1500 |

100 |

6 |

70 |

2400 |

1400 |

6500x3800x4740 |

Guarantee period:

Our product quality guarantee period is 12 months from B/L date. During guarantee period, we will provide spare parts without any charge in case of quality discrepancy caused by us. If the malfunctions are caused by customers’ incorrect operations, we will provide customers spare parts at cost price. We also can offer flexible extended warranties according to the actual situation.

After-sales services:

Our engineer can go to your factory for installation and showing operation details on condition of you provide the round-trip air tickets, visa formalities, food and accommodation. In turn, your engineers can come to our factory for learning the installation, operation and maintenance for free.

Why Choose Us:

1. We will run the machine for a few days, and use your materials to do the test. Only guarantee the machine shows best performance, and then we will ship out.

2. Our elite teams can provide you professional, customized, and all-round services around the clock. If you need any help, contact us by WHATSAPP, Skype, Email or Telephone.

How can we provide you efficient services (metal processing solution):

There are Three Steps as following:

1. Gather your requirements based on your real working situation.

2. Analyze your information and provide our feedback.

3. Offer options based on your specific needs. For instance, reg. standard products, we can offer professional recommendations; reg. non-standard products, we can offer professional designing.