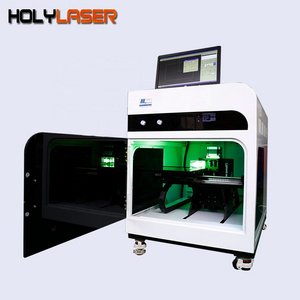

1.Equipment with special designed high power diode pump laser,

3D laser crystal engraving machine

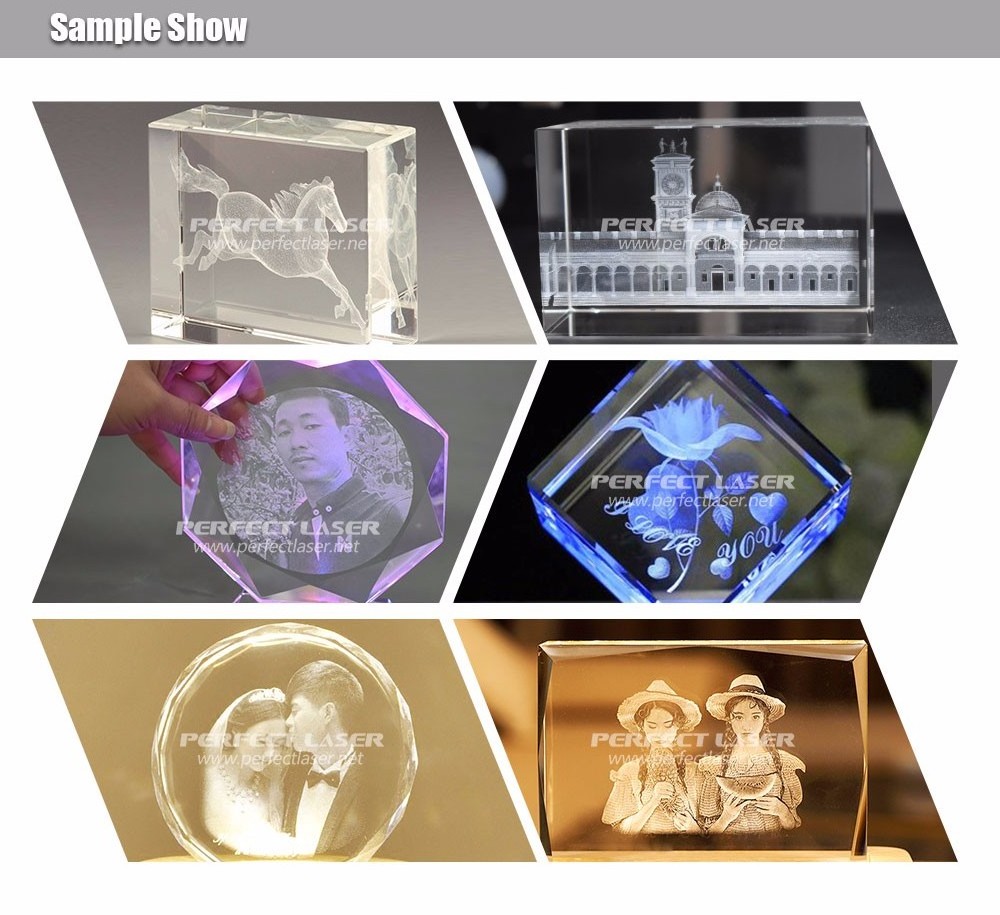

have inside laser engraving and material surface engraving function. Carving technology is a world leading level.

2.Using pulse laser power constant technology, the use of special laser mode greatly improve the quality of laser engraving.

3.The automatic laser positioning system is configured so that the

3D laser crystal engraving machine

can track the optical path. And a high-precision motion control system is adopted to ensure the high-quality engraving operation of the finished product.

4.The equipment adopts the modular equipment.

3D laser crystal engraving machine

is easy to maintain, the laser collimation technology and closed control system can be 24 hours of continuous operation.

5.We kept improving the image processing technology, and make lifelike carving products and an unprecedented engraving effect.

6.The first image sculpture “zero width” splicing technology, can make a wide range of joining together without any trace of carving.

7.Adopt humanized system, with "one-click" control sculpture to complete all the work functions to reduce the loss caused by manual operation errors.

8.The equipment can be plugged and used without special installation, so it is convenient to replace the job site at any time.

9.”Zero width” sculpture of splicing technology makes range up to 120*120*100 mm, meet the demand of personalized customization carving.

10.Inside crystal carving and material surface text’s speed is extremely high.

11.Suitable for any crystal materials carving and the surface of various materials logo engraving.