- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Shinestraw

-

Voltage:

-

by required

-

Dimension(L*W*H):

-

2300*1280*1380mm

-

Weight:

-

880 kg

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

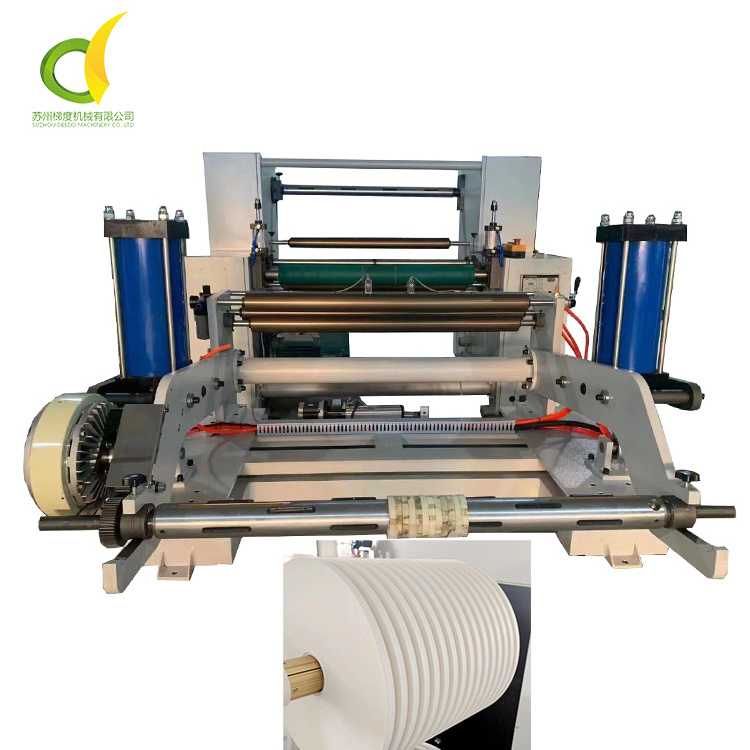

Paper Kraft Roll Converting Machinery Slitting Rewinding Machine

-

Function:

-

meltblown cloth, non-woven fabric, film, paper, tape Cuting

-

Max.cutting width:

-

800-2200mm

-

Max. Unwinding Diameter:

-

950mm

-

Max.Rewinding Diameter:

-

800-2200mm

-

Min cutting width:

-

13.5mm

-

Speed:

-

120m/min

-

Precision:

-

±0.10mm

-

Power Supply:

-

2.2kw---4kw

Quick Details

-

Type:

-

Slitting Rewinder

-

Production Capacity:

-

100%

-

Max. workable width:

-

2200mm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Shinestraw

-

Voltage:

-

by required

-

Dimension(L*W*H):

-

2300*1280*1380mm

-

Weight:

-

880 kg

-

Marketing Type:

-

Hot Product 2023

-

Product name:

-

Paper Kraft Roll Converting Machinery Slitting Rewinding Machine

-

Function:

-

meltblown cloth, non-woven fabric, film, paper, tape Cuting

-

Max.cutting width:

-

800-2200mm

-

Max. Unwinding Diameter:

-

950mm

-

Max.Rewinding Diameter:

-

800-2200mm

-

Min cutting width:

-

13.5mm

-

Speed:

-

120m/min

-

Precision:

-

±0.10mm

-

Power Supply:

-

2.2kw---4kw

Paper Kraft Roll Converting Machinery Slitting Rewinding Machine

Products Description

paper slitter machine is suitable for cutting big rolling packaging materials such as paper, paper board, kraft paper, culture paper, printing paper, laser paper, aluminum foil paper, paper, label,sticker, copper foil, aluminum foil,film(OPP, PE, PVC,PP,PC), Non-woven cloth,melt-blown fabric .etc. Widely used in paper industry and printing industry.

Stable Performance Paper Roll Slitting Machine with Belt Pulley The slitter is the corollary equipment of automatic die cutting machine, which is suitable for slitting narrow paper web.It has automatic meter count and number count, quantity and length preset and decelerate till stopping functions.Auto Magnetic powder control for unwinding and rewinding.

Photoelectric eyes rectification for unwinding, synchronous belt to conveyor in internal structure.Distinctive machine design will improve working efficiency and reduce operation labor intensity , which is the optimal choice for narrow material slitting.

The whole machine structure is compact, fast and with high efficiency. Operation is easy and steadily

Photoelectric eyes rectification for unwinding, synchronous belt to conveyor in internal structure.Distinctive machine design will improve working efficiency and reduce operation labor intensity , which is the optimal choice for narrow material slitting.

The whole machine structure is compact, fast and with high efficiency. Operation is easy and steadily

Control Panel:

You can set slitting speed,running length,unwinding and rewinding tension on it. It is very easy for worker to operate the

machine.

Slitting Blades:

This machine is standard equipped with full sets of slitting blades, min sltting width is 9mm. if you want to slit smaller width,you can customize self-lock knives. It's easy to adjust the slitting width based on your products.

Edge / line Position Controller:

These photoelectric sensors are used to guide the rough material to make sure the slitting

rewinding effect is good.The photo sensors concentrate on the edge of the material. You can choose between a single sensor and two sensors.

You can set slitting speed,running length,unwinding and rewinding tension on it. It is very easy for worker to operate the

machine.

Slitting Blades:

This machine is standard equipped with full sets of slitting blades, min sltting width is 9mm. if you want to slit smaller width,you can customize self-lock knives. It's easy to adjust the slitting width based on your products.

Edge / line Position Controller:

These photoelectric sensors are used to guide the rough material to make sure the slitting

rewinding effect is good.The photo sensors concentrate on the edge of the material. You can choose between a single sensor and two sensors.

Product Paramenters

|

Model

|

SS1300

|

SS1600

|

SS1800

|

SS2200

|

|

Sitting speed

|

80-100m/min

|

80-100 m/min

|

80-100 m/min

|

80-100 m/min

|

|

Blades number

|

8pcs

|

10pcs

|

11pcs

|

12pcs

|

|

Rewinding wallboard

|

Both side

|

Both side

|

Both sides

|

Both sides

|

|

Max width of web

|

1300mm

|

1600 mm

|

1800mm

|

2200mm

|

|

Max unwinding diameter

|

800mm

|

800 mm

|

850mm

|

850mm

|

|

Max rewinding diameter

|

450mm/600mm

|

500 mm/600mm

|

550 mm/600mm

|

550mm/600mm

|

|

Min cutting width

|

13.5mm

|

13.5 mm

|

13.5mm

|

13.5mm

|

|

Max cutting width

|

1300mm

|

1600 mm

|

1800mm

|

2200mm

|

|

Positioning precision

|

±0.10 mm

|

±0.10 mm

|

±0.10 mm

|

±0.10mm

|

|

Main motor power

|

3kw/4kw

|

4 kw/5.5kw

|

5.5kw/8.5kw

|

6kw/9kw

|

|

Overall size

|

2300*2100*1350mm

|

2300*2400*1350mm

|

2300*2600*1380mm

|

2300*2800*1410mm

|

|

Weight

|

1200kg

|

1500kg

|

1700kg

|

2000kg

|

Details Images

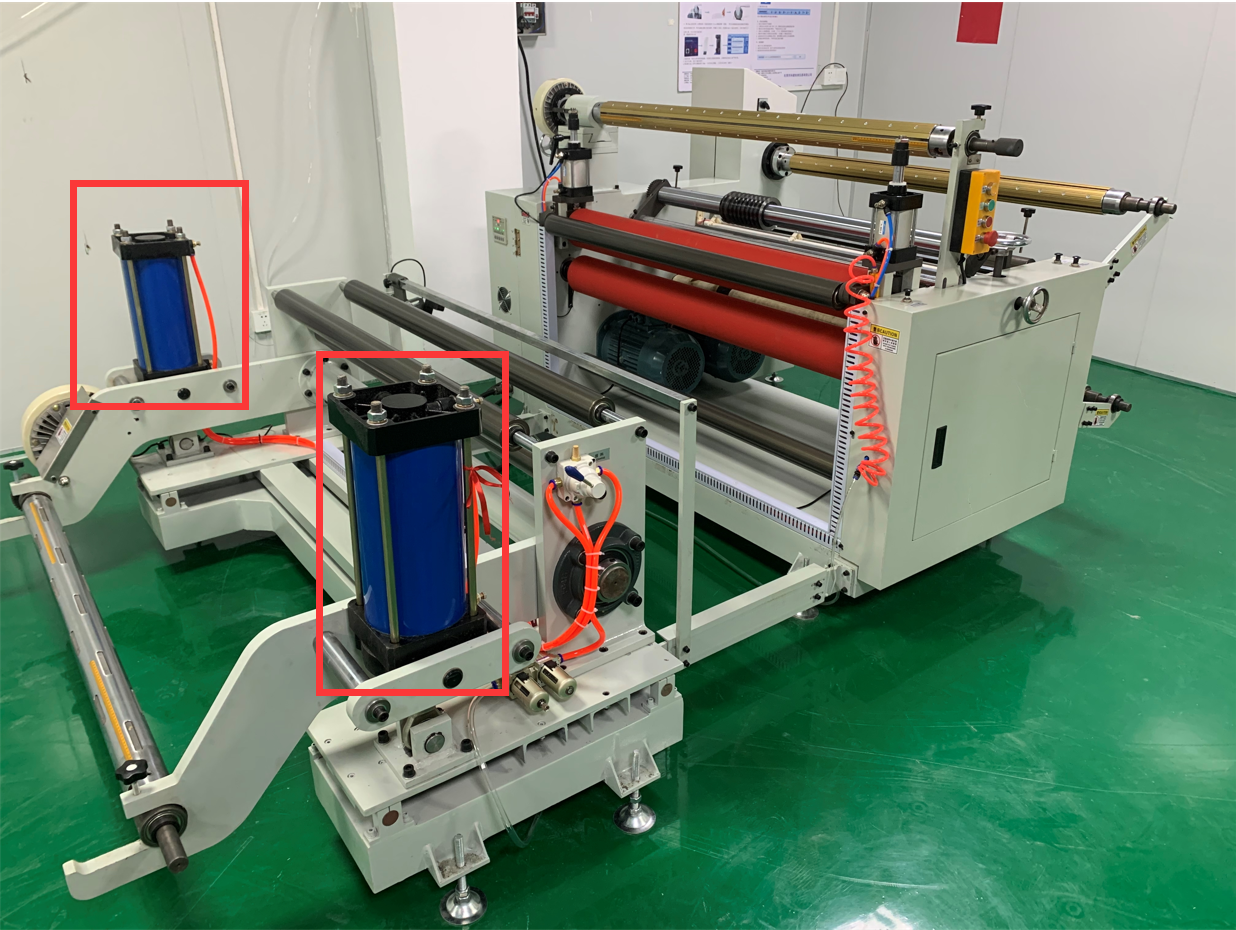

Automatic feeding cylinder

Automatic feeding cylinder,

Maximum unwinding diameter 1m,

and can also be customized.

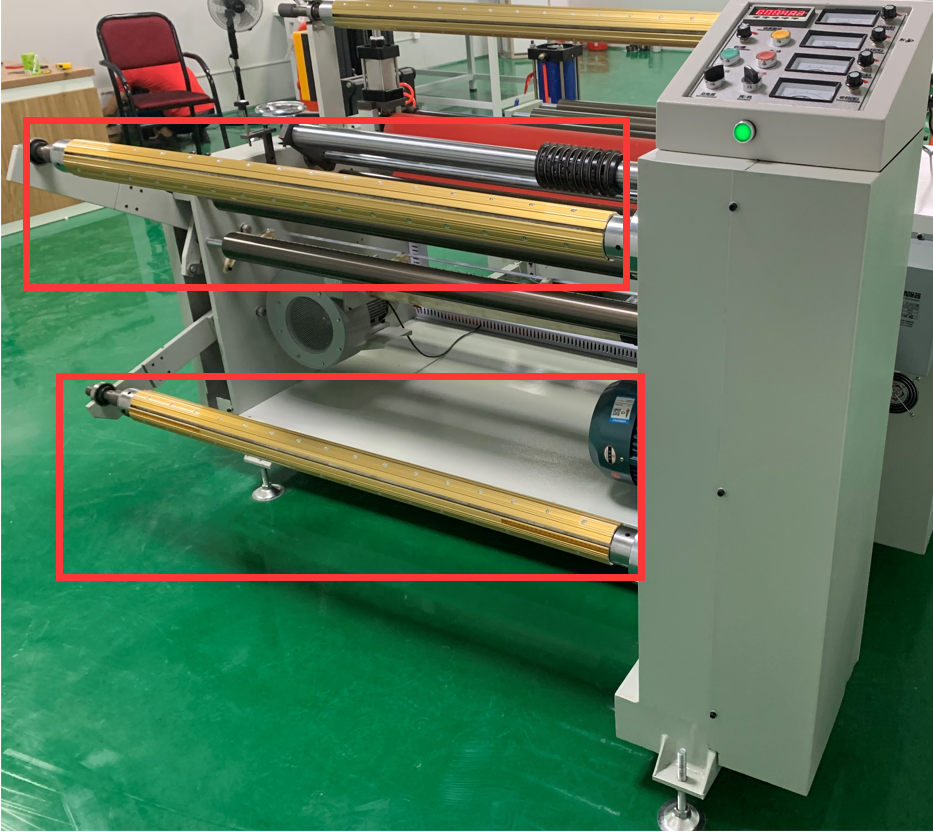

Rewinding air shaft

The maximum winding diameter is 1000mm, which can be customized.

Automatic EPC Guiding Controller System

Web Guiding Controller System to keep the material in line.

Count-meter display &

Tension adjustment

automatic stop when a certain number of linear meters is reached.

Tension can be adjusted within a certain range.

collect waste

The cut waste is widely collected on the air shaft, and the narrow left and right sides are sucked out.

Top and bottom knives

Main Features

1. Two winding shafts, more efficency;

2. Air expanding shaft, clamp more tighten, no slippage;

3. Magnetic powder control tension.Tension controllable and output torque balancing by magnetic powder brake actuator;

4. High speed waste material blowing fan;

5. Full rotary slitting blade can be adjusted.

6. Fast closing to knife device, locking upper knife shaft.Air cylinder control the pulling roller up and down.

7. Frequency motor to control speed.

8. 3 inch inflatable unwind shaft and 2 3 inch inflatable rewind shaft.

9.It has the functions of easy operation, high precision, good stability and low noise.

2. Air expanding shaft, clamp more tighten, no slippage;

3. Magnetic powder control tension.Tension controllable and output torque balancing by magnetic powder brake actuator;

4. High speed waste material blowing fan;

5. Full rotary slitting blade can be adjusted.

6. Fast closing to knife device, locking upper knife shaft.Air cylinder control the pulling roller up and down.

7. Frequency motor to control speed.

8. 3 inch inflatable unwind shaft and 2 3 inch inflatable rewind shaft.

9.It has the functions of easy operation, high precision, good stability and low noise.

Workshop Show

Final Product

Software patent certificate

patent certificate

Company other certificates

Hot Searches