- Product Details

- {{item.text}}

Quick Details

-

Application:

-

metallurgical Industry/medical device industry

-

Grade:

-

Gr1 Gr2 Gr3 Gr4 Gr5 Gr7 Gr9 Gr12 Gr23

Quick Details

-

Powder Or Not:

-

Not Powder

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

Firmakes Titanium

-

Application:

-

metallurgical Industry/medical device industry

-

Grade:

-

Gr1 Gr2 Gr3 Gr4 Gr5 Gr7 Gr9 Gr12 Gr23

Product Description

Specification

|

Product Name

|

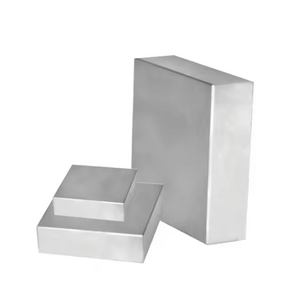

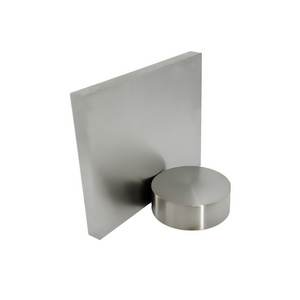

Titanium Forgings

|

|

Execution standard

|

ASTM B381,ASTM F67,ASTM F136,AMS4928,ASTM B348,ASMESB348

|

|

Application

|

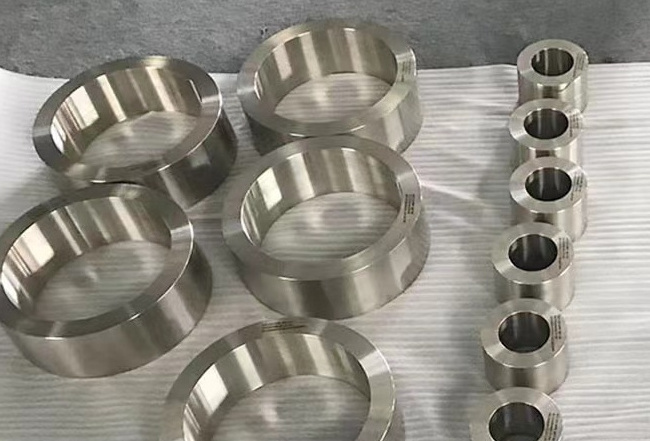

Titanium and titanium alloy discs and rings are mainly applied in petrochemical industry, metallurgical Industry and medical device industry.

|

|

Size1

|

Disc External Diameter: Ø30~Ø1500mm Section Height: 35~140mm

|

|

Size2

|

Ring External Diameter:Ø50~Ø1300mm Internal Diameter: Ø30~Ø900mm Section Height: 35~250mm Wall Thickness: 10~400mm

|

|

Material

|

Gr1 Gr2 Gr3 Gr4 Gr5 Gr7 Gr9 Gr12 Gr23 UNS R50250 UNS R50400 UNS R50550 UNS R50700 UNS R56400 UNS R52400 UNS R56320 UNS R53400 UNS R56401 UNS R58640 UNS R54620 UNS R56620 UNS R54520 etc.

|

|

Features

|

Low density, High specific strength,Excellent corrosive resistance,Rustless Good thermal stability,Good thermal conductivity,Biological features, plasticity, etc.

|

|

Surface treatment

|

Lathing and chamfering;Acid Surface or Polishing;We adopt automatic cleaning machine and rotary brush to clean the surface and then rinse the surface under high pressure. Products are clean and dust free, and have longer acid-resistant service life.

|

|

Surface quality

|

The surface roughness (Ra) of two end faces should not be more than 3.2lμm (which is subject to requirements of ultrasonic inspection). The surface roughness (Ra) of external and internal side faces should not be more than 12.5μm (and Ra should not be more than 3.2μm when external circular face accepts ultrasonic flaw detection). The chamfer’s radius is between 5~15mm. The product surface should not have visible flaws, such as cracks, backfins and double skin. Local flaws on the surface is allowed to

remove by polishing and grinding. The depth of removal should not be more than corresponding dimensional tolerance, and maximum acceptable dimension should be ensured. The ratio of depth of removal to width of removal should not be more than 1:6 at end faces, and should not be more than 1:10 at external and internal side faces. External side face should be polished and grinded along its axial. |

|

Physical properties

|

Better elongation and strength. No deformation after cold bending. No cracks after flattening and flaring. Wires with the diameter of over 3mm have no discontinuity, pores, laminations, cracks, and metal or non-metal impurities.

|

|

Delivery status

|

Annealed state (M), hot processing state (R) and cold processing state (Y) (annealing and ultrasonic flaw detection)

|

|

Quality Control

|

We use domestic first-class forging and pressing equipment and production process controlled by high-accuracy tolerance, so the products’ dimensional tolerance is controlled at a high level. Initial, in-process and final inspections are carried out to ensure product quality.

|

|

Material selection

|

0A-grade, 0-grade and 1-grade sponge titanium produced by the largest sponge titanium manufacturer in China. Test on physical and chemical properties can ensure that each batch of goods meet industrial standards. Each titanium disc and each titanium ring are tested and inspected within allowable dimensional tolerance.

|

|

Checkout

|

Test on mechanical properties, test on chemical ingredients, and ultrasonic detection.

|

Hot Searches