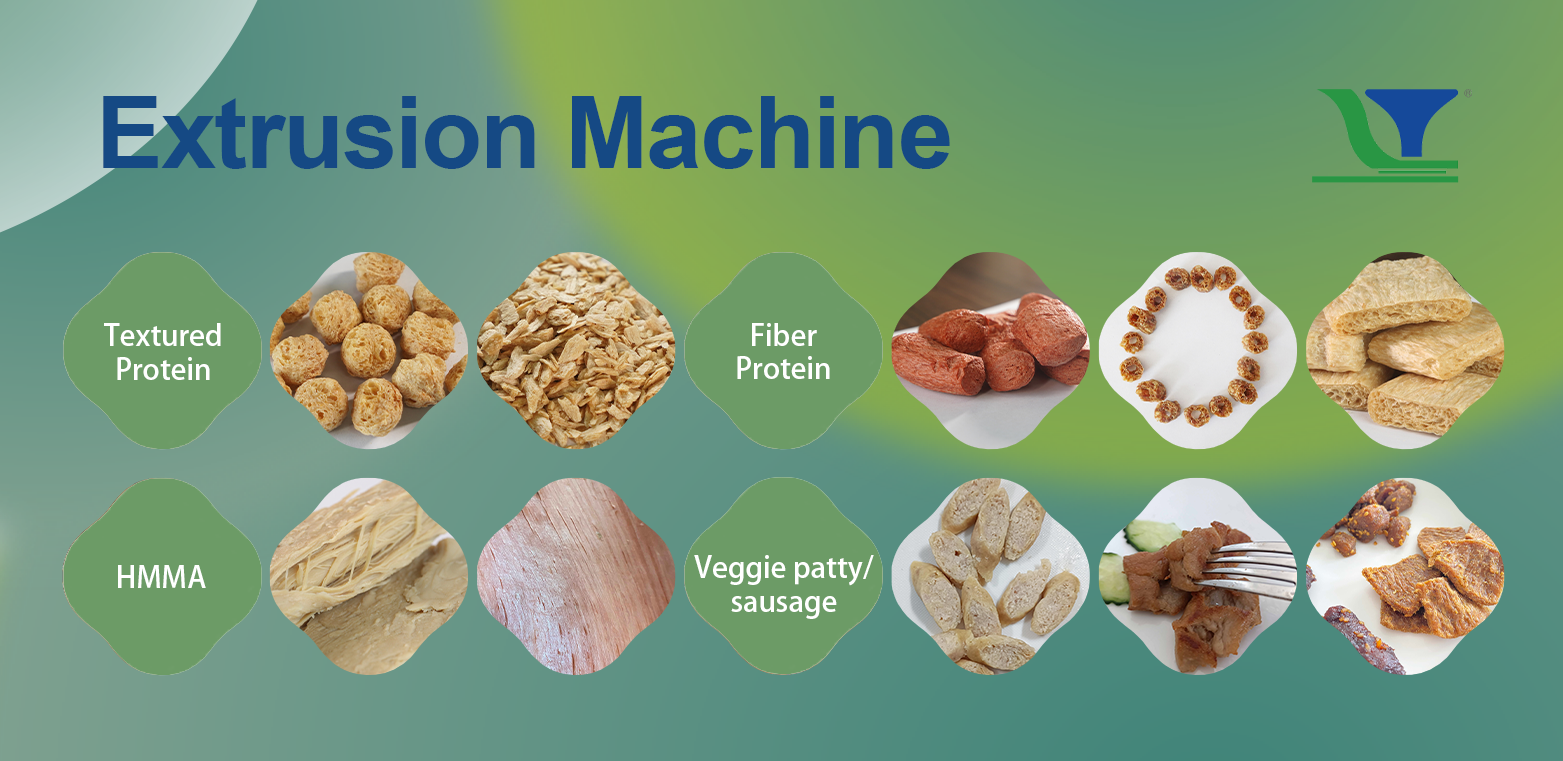

1.The extrusion process is flexible, can make use of different materials to get various

Fiber protein.

2.By change dies and adding some accessory equipment, same line is able to produce various shapes protein products, like cylinder,

sheet protein, etc.

3.We can supply extrusion solution from lab scale 15kg/hour to Industrial production 2000kg/hour capacity.

- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/ 50Hz

-

Power:

-

75-183kw

-

Weight:

-

4000 KG

-

Application:

-

TVP

-

Product name:

-

Textured Soy Protein Production Line

-

Capacity:

-

150-300kg/h,300-500kg/h,800-1000kg/h

-

Material:

-

Stainless Steel

-

MOQ:

-

1 Set

-

Color:

-

Silver

-

Keywords:

-

Food Grade Textured Soy Protein

-

Advantage:

-

High Efficiency

-

Function:

-

Multifunction

-

After Warranty Service:

-

Field maintenance and repair service

Quick Details

-

Marketing Type:

-

New Product 2022

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

LT

-

Voltage:

-

380V/ 50Hz

-

Power:

-

75-183kw

-

Weight:

-

4000 KG

-

Application:

-

TVP

-

Product name:

-

Textured Soy Protein Production Line

-

Capacity:

-

150-300kg/h,300-500kg/h,800-1000kg/h

-

Material:

-

Stainless Steel

-

MOQ:

-

1 Set

-

Color:

-

Silver

-

Keywords:

-

Food Grade Textured Soy Protein

-

Advantage:

-

High Efficiency

-

Function:

-

Multifunction

-

After Warranty Service:

-

Field maintenance and repair service

Products Description

Textured Soya Protein/Vegetarian Soya Meat/Soya Nugget Food Process Line takes Defatted soybean meal, pea protein, peanut meal etc as main raw materials. After mixing, extruding, cutting and drying, the meal becomes layer fiber texture, with meat chewy taste, these products are called TVP, TSP, Soya Chunks, Soya Protein, Soya Protein Crumbs etc.

These finished products have high protein; look and taste like meat; easy to absorbing oil, water and flavor; without cholesterol and animal fat, so it is widely used in meat products industry, fast food production, deep frozen food production, and all kinds of vegetarian snacks and food.

These finished products have high protein; look and taste like meat; easy to absorbing oil, water and flavor; without cholesterol and animal fat, so it is widely used in meat products industry, fast food production, deep frozen food production, and all kinds of vegetarian snacks and food.

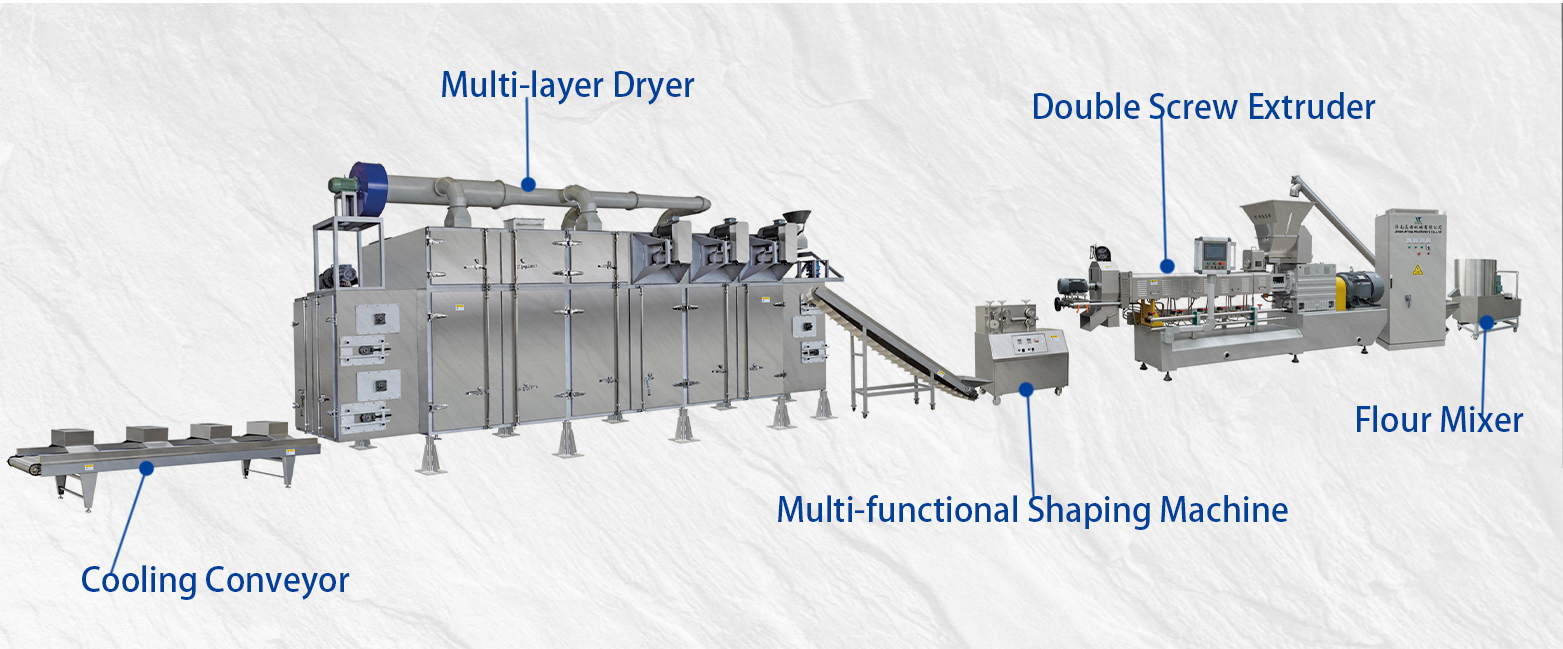

Process Flow Chart

Flour Mixer → Double-screw Extruder →Air Conveyer → Multi-layer Dryer → Coating Line → Cooling Machine

|

Model

|

Output

|

Size

|

|

ETT65

|

200-500KG/h

|

13500*2300*2400mm

|

|

ETT78

|

300-800KG/h

|

14500*2300*2400mm

|

|

ETT98

|

800-2000 KG/h

|

17000*2300*2400mm

|

|

ETT120

|

1500-3000KG/h

|

25000*4000*8000mm

|

Machine Details

This production line is mainly used for the production of Textured Protein. The production

line uses defatted soybean meal and peanut meal as the main raw materials, and forms lamellar tissue fibers after stirring, extrusion and shearing.

line uses defatted soybean meal and peanut meal as the main raw materials, and forms lamellar tissue fibers after stirring, extrusion and shearing.

Cold Treat Extrusion Pet FOODS Making Machine

The production line joins the Series of Packing Machine. It integrates feeding, measuring, bag filling, date printing, inflation (exhaust), output and other functions into one, which greatly improves the measurement accuracy and efficiency.

The raw materials pass through the fully automatic batching machine, extruder, and cooling section to form high-moisture protein. The high-moisture protein passes through the molding machine and the flattening conveyor belt to make vegetarian patties.

Our Company

Shandong Light M & E Co., Ltd

is professional manufacturer of

food snacks machines

, including

mixer, extruder, dryer, oven, roaster, fryer, flavoring machine etc

.We have an elite sales team who can recommend the most suitable products for you, and a group of professional mechanical engineers who have more than twenty years’ experience. Our senior mechanical are masters of machine manufacture, and our after-sales service personnel are reliable experts in food processing field. All of these guarantee Best Quality and Excellent Performance, and keep you free from further production worries.

We have over 20 years experiences in this industry and exported to 118 countries. We have got CE and ISO9001 certificates and 18 atents in the past years. We own 25000 square meters factory with 10 departments constituted by 120 persons .

We have over 20 years experiences in this industry and exported to 118 countries. We have got CE and ISO9001 certificates and 18 atents in the past years. We own 25000 square meters factory with 10 departments constituted by 120 persons .

FAQ

Q: Are you manufacturer or trader?

A: We are professional manufacturer for more than 20 years experience, with professional engineering and after-sales team.

A: We are professional manufacturer for more than 20 years experience, with professional engineering and after-sales team.

Q: What service you supply?

A: We supply 7*24h service Pre-sale, in-sale and after-sale. ODM and OEM service are also available.

Q: Do you supply relevant spare parts to buyers?

A: Yes, we will supply all spare parts of machine to customers.

Q: If power supply different from yours, can you supply suitable machines?

A: Yes, motor voltage is customized, we will make it according to your requirements. Most commonly are 318V, 415V, 50/60HZ; 440V, 50/60HZ and 220V, 60HZ.

Q: Besides kurkure cheetos machine, what other machine you can supply?

A: We are able to supply kinds of food machine, includingpuff snack,breakfast cereal, corn flakes, tortilla chips, bugles, fried snack, potato chips and etc.. It will complete solution from A to Z.

Hot Searches