Increase the output of finished goods. The output increased from 20-30per

minute to 55-70 per minute. At the same time as increasing the output,

the electricity consumption remains at 8.5 kw

.

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

unitely

-

Voltage:

-

380V 50HZ, 380V

-

Power:

-

8.5 KW, 8.5 KW

-

Dimension(L*W*H):

-

3100*1600*1900mm

-

Weight:

-

2400 kg, 3150kg

-

Marketing Type:

-

Hot Product 2023

-

Certification:

-

ce

-

Cup sizes:

-

44oz(molds can be changed)

-

Air supply:

-

0.5-0.8mpa 0.4m³/min,

-

Paper specification:

-

210-350g/㎡(single /double pe coated paper )

-

Speed:

-

55-70 pcs per min

-

Overall size:

-

3100*1600*1900mm

-

After-sales Service Provided:

-

Service Machinery Overseas

Quick Details

-

Production Capacity:

-

55-70 pcs per min

-

Processing Type:

-

Paper product making machine

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

unitely

-

Voltage:

-

380V 50HZ, 380V

-

Power:

-

8.5 KW, 8.5 KW

-

Dimension(L*W*H):

-

3100*1600*1900mm

-

Weight:

-

2400 kg, 3150kg

-

Marketing Type:

-

Hot Product 2023

-

Certification:

-

ce

-

Cup sizes:

-

44oz(molds can be changed)

-

Air supply:

-

0.5-0.8mpa 0.4m³/min,

-

Paper specification:

-

210-350g/㎡(single /double pe coated paper )

-

Speed:

-

55-70 pcs per min

-

Overall size:

-

3100*1600*1900mm

-

After-sales Service Provided:

-

Service Machinery Overseas

Recommend Products

3D Showroom

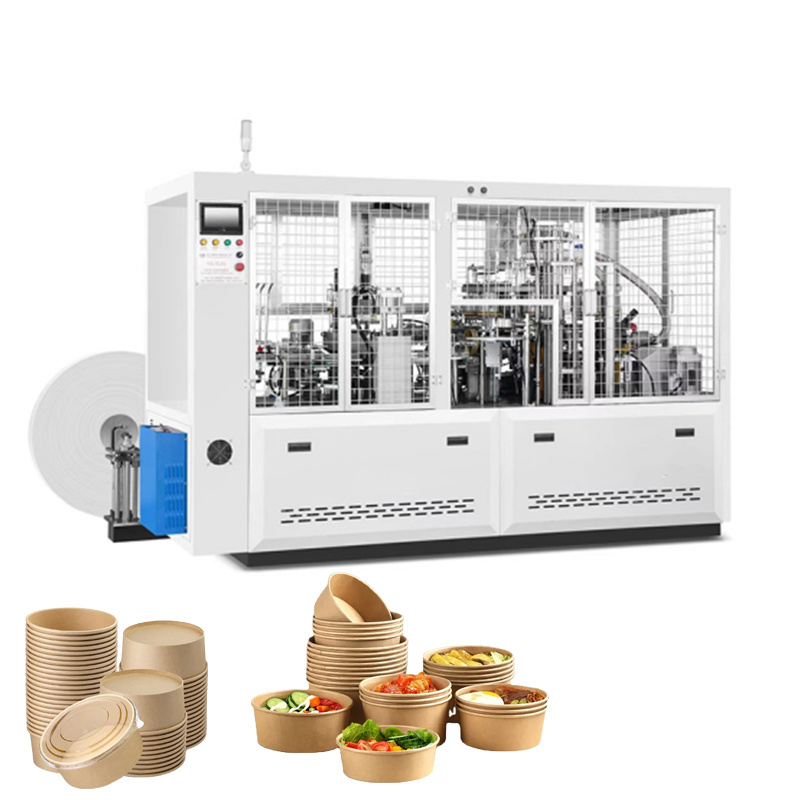

Product Paramenters

|

Bowl sizes

|

44oz T:140-185mm; B.:45-110mm; H:110-160mm ; K:5-12mm

|

|

Paper material

|

210-350g/㎡(single /double pe coated paper )

|

|

Speed

|

55-70 pcs per min

|

|

Voltage

|

380V 50Hz

|

|

Total power

|

8.5 KW

|

|

Air requirement

|

0.5-0.8mpa 0.4m³/min

|

|

Weight

|

3150kg

|

|

Overall size

|

3100*1600*1900mm

|

|

Packing size

|

3160x1450x2150mm

|

Products Description

1. Paper Feeding

2.sensors inspection

3.PLC touch screen control

4.Ultrasoic working

5.hot air device

6. wasting paper feeder

7. open cam and gear driving system

8. bottom wasting paper out

Main Advantage

The size of the equipment is reduced, the structure is more reasonable, the working procedure is more simple, from the original 3 turntables reduced to 1 turntable plus a Small Cup turntable, Cup closing is more simple, convenient and quick. Can Be added to the robot-style automatic cup-closing options.

The bottom cutting knife is arranged at the bottom of the cup mould, and the boom paper is cut off and directly rushed into the bottom of

the cup barrel to avoid the bottom turning phenomenon.

This product equipment adopts the light-controlled non-contact multi-point switch, which can detect the abnormal work, realizes the function of automatic alarm and shutdown, protects the parts of each part of the machine from collision,

and greatly improves the stability and life of the machine.

Drum position using three-in-one cam drive around the Cup holder, the work is no noise, drum action more reliable and stable, this technology is the first in China.

Hot Searches