- Product Details

- {{item.text}}

Quick Details

-

Application:

-

all kinds of buildings

-

Design Style:

-

insulaiton

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Ten-lead

-

Model Number:

-

TlA-50

-

Type:

-

phenolic foam, Other Fireproofing Materials

-

Shape:

-

panel

-

Material:

-

phenolic foam

-

Core Material:

-

phenolic foam

-

Combustibility Property:

-

Class 0(BS476 Part 6&7) Class A (ASTM E84)

-

Thermal Conductivity:

-

0.025 w/mk

-

Foam Density:

-

40kg/m3 - 60kg/m3

-

Working Temperature:

-

-250 ℃ to +150℃

Quick Details

-

Warranty:

-

1 Year

-

After-sale Service:

-

Online technical support

-

Project Solution Capability:

-

Others

-

Application:

-

all kinds of buildings

-

Design Style:

-

insulaiton

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

Ten-lead

-

Model Number:

-

TlA-50

-

Type:

-

phenolic foam, Other Fireproofing Materials

-

Shape:

-

panel

-

Material:

-

phenolic foam

-

Core Material:

-

phenolic foam

-

Combustibility Property:

-

Class 0(BS476 Part 6&7) Class A (ASTM E84)

-

Thermal Conductivity:

-

0.025 w/mk

-

Foam Density:

-

40kg/m3 - 60kg/m3

-

Working Temperature:

-

-250 ℃ to +150℃

Description

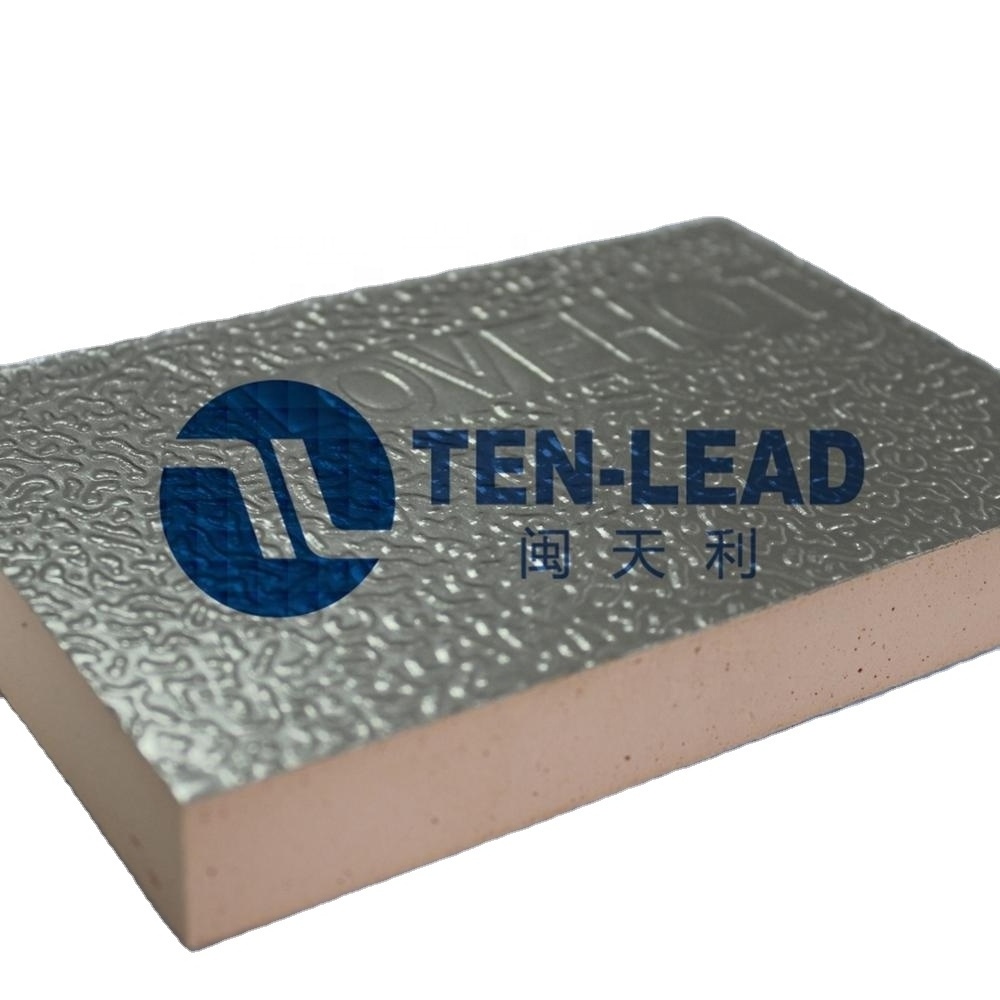

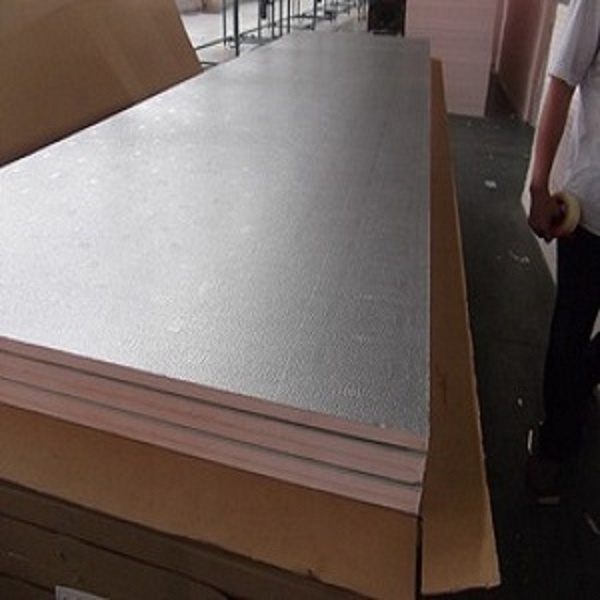

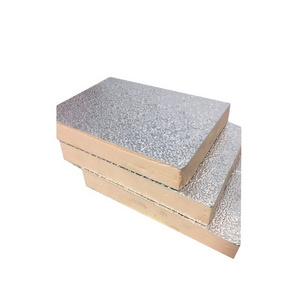

The GOOT® Phenolic Foam Pre-insulated Duct panel system the most advanced and nnovative energy saving system of air-distribution ductwork available worldwide. Ductwork is fabricated using rigid insulation panels in sections up to 3.95m-4m and can provide the optimum energy saving and environmental solution in comparison with other types of ductwork. The system consists of Phenolic Pre-insulated Duct Panels, fabrication methods, jointing systems and a complete line of accessories to produce a System where air leakage can be reduced to a fraction of that typical of sheet metal ductwork.

Advanges

Advantages compared to traditional insulated Sheet Metal Ductwork:

Do it in one time, no lag insulation required, save the labor and cost.

Save the buiding space

Very light, decrease the total weight of building

Little air leakage by flange joint connectting

Low thermal conductivity, no condensation and energy saving

Closed cell foam, good acoustic insulation

Fire proof, no smoke when exposing to fire

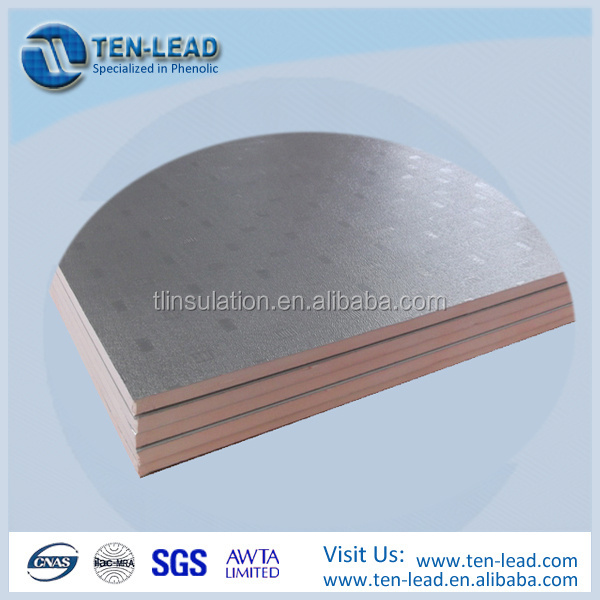

Faced with aluminum foil, it’s water proof and anti-microbial

CFC and HCFC free, environment friendly

Parameters

|

Item |

Unit |

Specification |

|

Panel Structure |

Alu./Foam/GI |

|

|

Standard Panel Size |

mm |

3950*1200*20 |

|

Alu. Foil Thickness |

mm |

0.06 |

|

Galvanized/Alu.sheet/Painted Steel Sheet Thickness |

mm |

0.18 |

|

Foam Density |

kg/m3 |

60 |

|

Thermal Conductivity |

w/m.k |

0.021 |

|

Compressing Strength |

Mpa |

0.25 |

|

Bending Strength |

Mpa |

1.2 |

|

Combustibility Property |

Class 0 (BS476 Part 6 & 7) Class A (ASTM E84) |

|

|

Water Absorption |

% |

1.9 |

|

Max Smoke Density |

% |

2 |

|

Dimension Change |

% |

0.3 |

|

Working Temperature |

°C |

-250- +150 |

|

Maximum Allowable Wind Velocity |

m/s |

≤15 |

|

Continuous Running Maximum Temperature |

°C |

≤120 |

Factory and Workshop

Lab

Certificates

Products

Applications

Project Case

Wecome to our business Site, please let us know your detailed requirement so that we can quote you and offer you the right things at our earliest time!