- Product Details

- {{item.text}}

Quick Details

-

Power:

-

370W, 750 w

-

Dimension(L*W*H):

-

85x35x74cm

-

Weight:

-

23 KG

-

Core Components:

-

filter pump

-

Product Name:

-

Diatomaceous earth filter Machine for Wine with Filter Pump

-

Material:

-

Stainless Steel

-

Function:

-

Wine / juice filter

-

Type:

-

Diatomite earth filter electric

-

Size:

-

82x35x74cm

-

Production capacity:

-

0.5-1 tons/ hour

-

Production pressure:

-

≤0.3Mpa

-

Number of filters:

-

15 pcs

-

Filters area:

-

1 ㎡

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Dibosh

-

Voltage:

-

220V

-

Power:

-

370W, 750 w

-

Dimension(L*W*H):

-

85x35x74cm

-

Weight:

-

23 KG

-

Core Components:

-

filter pump

-

Product Name:

-

Diatomaceous earth filter Machine for Wine with Filter Pump

-

Material:

-

Stainless Steel

-

Function:

-

Wine / juice filter

-

Type:

-

Diatomite earth filter electric

-

Size:

-

82x35x74cm

-

Production capacity:

-

0.5-1 tons/ hour

-

Production pressure:

-

≤0.3Mpa

-

Number of filters:

-

15 pcs

-

Filters area:

-

1 ㎡

Product Description

Professional Grade Multifunctional Diatomaceous Earth Filter

I

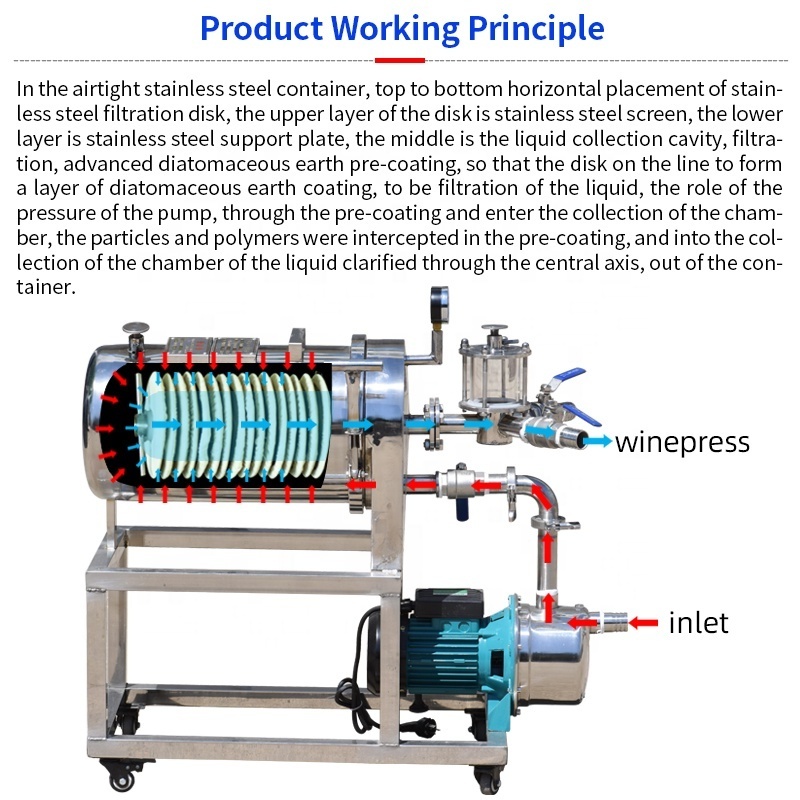

n the airtight stainless steel container, top to bottom horizontal placement of stainless steel filtration disk, the upper layer of the disk is stainless steel screen, the lower layer is stainless steel support plate, the middle is the liquid collection cavity, filtration, advanced diatomaceous earth pre-coating, so that the disk on the line to form a layer of diatomaceous earth coating, to be filtration of the liquid, the role of the pressure of the pump, through the pre-coating and enter the collection of the chamber, the particles and polymers were intercepted in the pre-coating, and into the collection of the chamber of the liquid clarified through the central axis, out of the container.

Specification

|

item

|

value

|

|

Name

|

Diatomaceous earth filter Machine for Wine with Filter Pump

|

|

Brand Name

|

Dibosh

|

|

Processing Types

|

Wine, fruit juice , Alcohol

|

|

Voltage

|

220V

|

|

Power

|

750W

|

|

Dimension(L*W*H)

|

82x35x74cm

|

|

Weight

|

23KG

|

|

Machinery Capacity

|

500-1000L

|

|

Core Components

|

filter pump

|

|

Key Selling Points

|

Easy to Operate

|

|

Marketing Type

|

Ordinary Product

|

|

Video outgoing-inspection

|

Provided

|

|

Material

|

Stainless Steel

|

|

Function

|

Wine / juice filter

|

|

Production capacity

|

0.5-1t/hour

|

|

Production pressure

|

≤0.3Mpa

|

|

Number of filters

|

15 pcs

|

|

Filters area

|

1 ㎡

|

Method of use

1-First, pour 1 catty of fine diatomaceous earth and 1 catty of coarse diatomaceous earth into the pre-coated container and wine mixing and stirring can be done, 1 kg of diatomaceous earth can be filtered 0.5~1 tons of wine; 2-Check whether the parts of the diatomaceous earth filtering machine equipment are connected well or not.

3-Connect the wine inlet to the working pump inlet 1, while slowly opening the regulating valve 1, outlet valve 2 and closing the outlet valve 3;.

4-Start the working pump, at the same time, pre-coating containers in the turbid liquid through the pump into the filter, turbid liquid in the diatomaceous earth also enters the machine and attached to the filter cloth, through the exit valve 2 and recycled to the pre-coating containers, and so on and so forth.

5 - Observe the filtrate from the glass sight glass whether to achieve a clear and transparent state, take a sample from the exhaust valve 4 to send for inspection, under normal circumstances, the liquid after 15 ~ 30 minutes or so after the cycle can meet the requirements.

6-after reaching the clarification, close the valve 2, open the valve 3, at this time after the filtration of the clarified wine can be bottled or stored separately.

7-This machine should be operated by professional personnel, do not close the outlet valves 2 and 3 when working, otherwise it will produce high pressure and damage the machine parts.

8-open the exhaust valve before starting the machine, close the exhaust valve when the air is exhausted, close the outlet valves 2 and 3, the regulating valve after stopping the machine, open the exhaust valves 4 and 5, and drain the liquid in the filter from the valve under the filter cartridge; 9-open the housing, unscrew the valve, and then open the valve to drain the liquid from the filter cartridge.

9-open the shell, unscrew the nut at the end of the shaft, remove the filter element, rinse the diatomaceous earth and adherents on the filter cloth with clean water, and then equip it in order for the next work.

Hot Searches