- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

chian

-

Brand Name:

-

KAHO

-

Model Number:

-

KAHO

-

Product name:

-

Borofloat Telescope Blank Custom Size Borosilicate Glass Sheet

-

Keywords:

-

Borofloat glass,borosilicate glass blank

-

Temperature resistance:

-

650℃

-

Light transmittance:

-

92%

-

Regular size:

-

1200*1000mm

-

Max size:

-

1500*1000mm

-

Color:

-

Clear glass

-

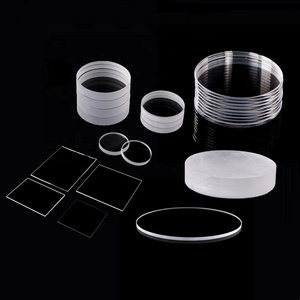

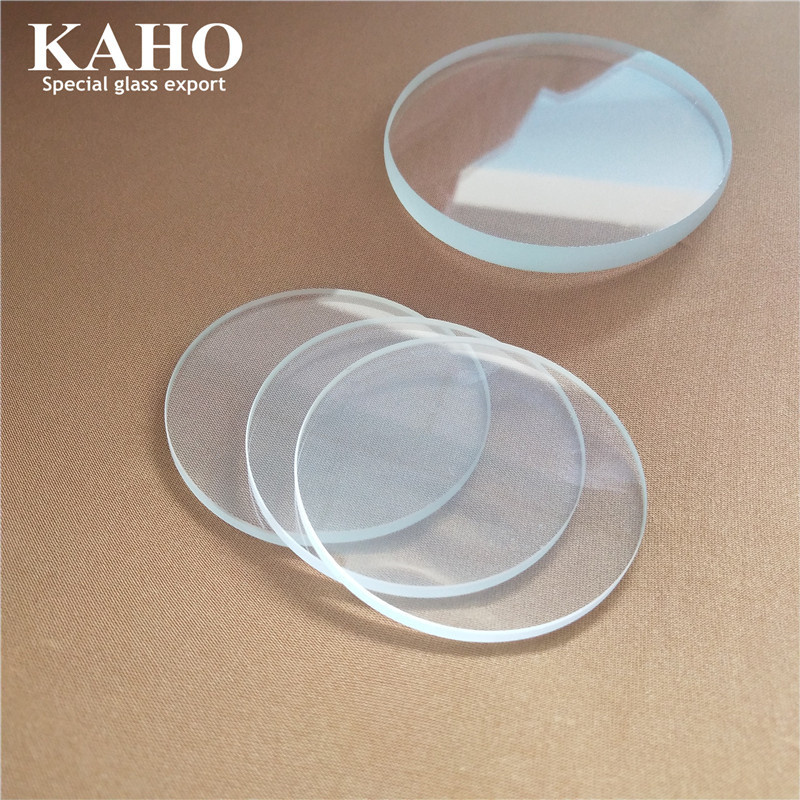

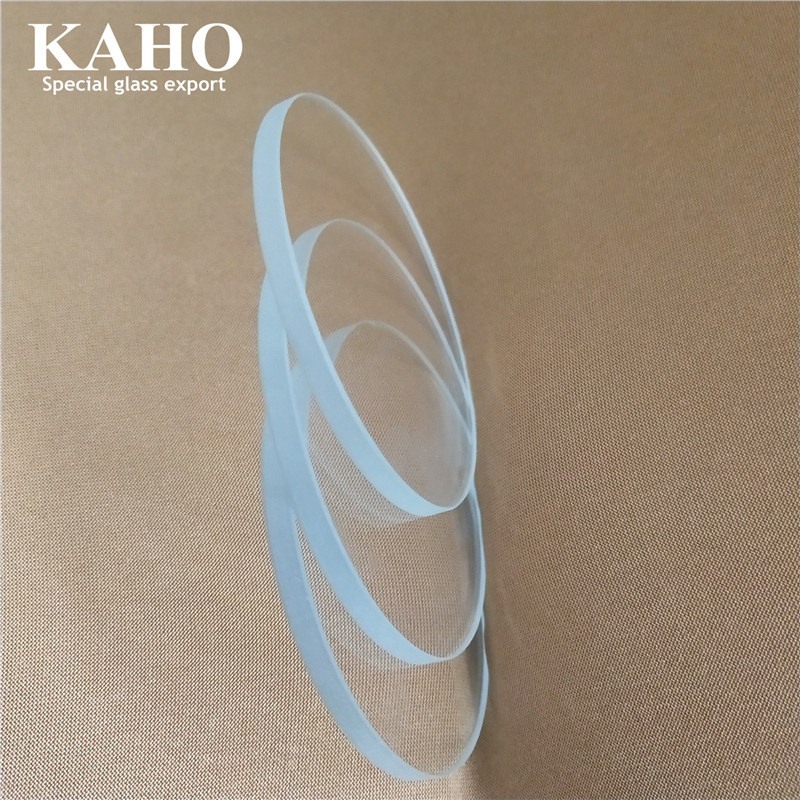

Shape:

-

Round,square or customized

-

MOQ:

-

10 Pcs

Quick Details

-

Application:

-

Supermarket, Workshop, Mall, Apartment, Villa, Hotel

-

Usage:

-

Industrial

-

Thickness:

-

1mm-19mm

-

Place of Origin:

-

chian

-

Brand Name:

-

KAHO

-

Model Number:

-

KAHO

-

Product name:

-

Borofloat Telescope Blank Custom Size Borosilicate Glass Sheet

-

Keywords:

-

Borofloat glass,borosilicate glass blank

-

Temperature resistance:

-

650℃

-

Light transmittance:

-

92%

-

Regular size:

-

1200*1000mm

-

Max size:

-

1500*1000mm

-

Color:

-

Clear glass

-

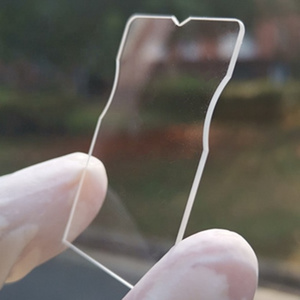

Shape:

-

Round,square or customized

-

MOQ:

-

10 Pcs

Borofloat Glass Telescope Glass Borosilicate Blank Custom Size Borosilicate Glass Sheet

01-Product Name:

Borosilicate glass also called high borosilicate glass.Both high borosilicate glass and quartz glass are high temperature resistant glass ,which can be different shape and size to meet your requirement.

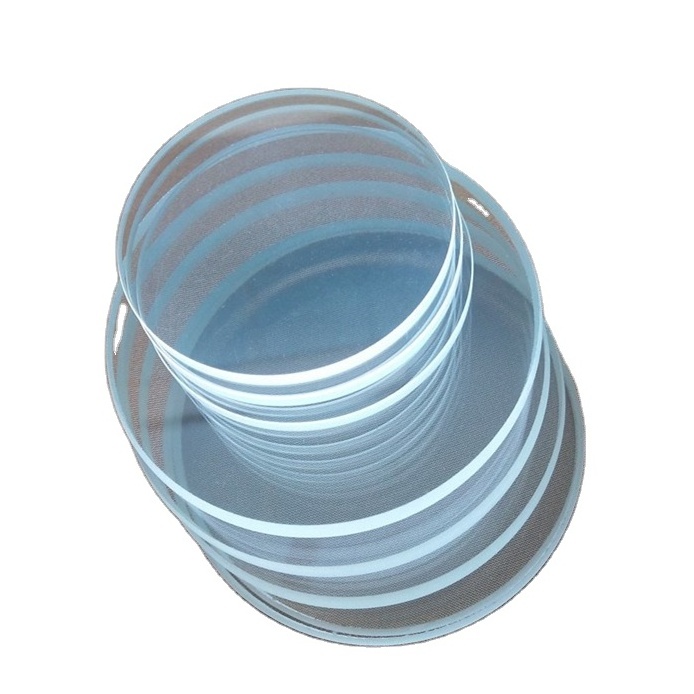

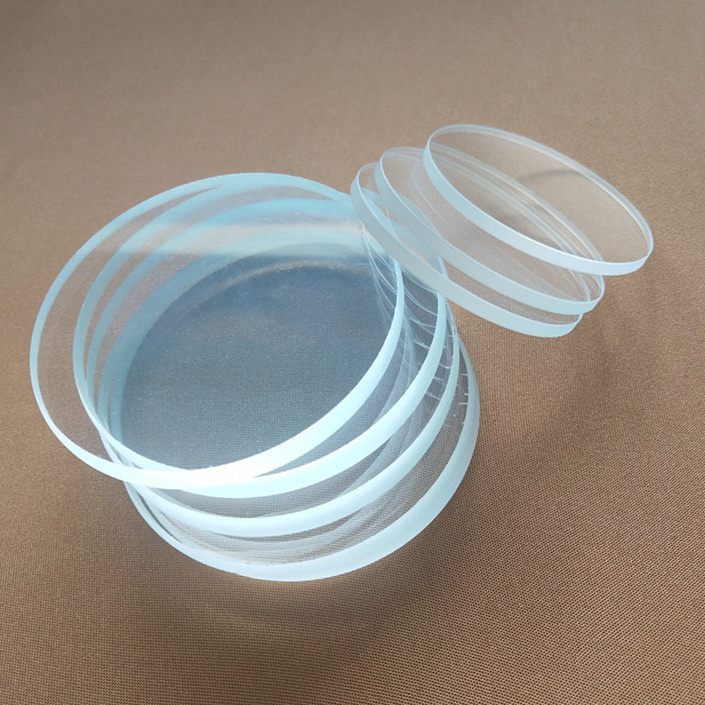

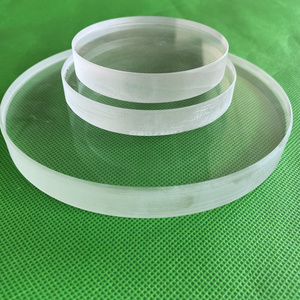

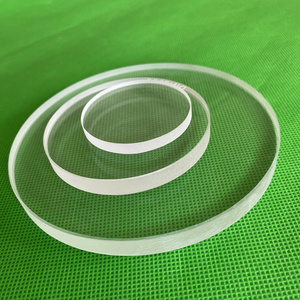

02-Product Preview:

The linear expansion coefficient of G3.3 high borosilicate glass is 3.3 ± 0.1 × 10-6 / K. It is a glass based on sodium oxide (Na2O), boron oxide (B2O3), and silicon dioxide (SIO2). The glass composition has a high content of borosilicate, which is boron: 12.5 ~ 13.5% and silicon: 78 ~ 80%, so this kind of glass is called high borosilicate glass. It belongs to glass in borosilicate glass. Acid, alkali and water resistance, excellent corrosion resistance, good thermal stability, chemical stability and electrical properties, so it has chemical resistance, thermal shock resistance, good mechanical properties, high temperature and other characteristics.

03-Difference between quartz glass and high borosilicate glass:

1. The composition is different: the high borosilicate glass composition is sodium oxide, boron oxide, silicon dioxide, among which the borosilicate content is higher: 12.5 ~ 13.5%, silicon: 78 ~ 80%; quartz glass composition is silicon dioxide: content is 99.99

2. Different temperature resistance: the high boron silicon temperature is at the strain temperature of 520ºC, and the softening temperature is 820ºC;

Quartz glass has a temperature of 1100ºC and a melting point of about 1700ºC

3. Quartz glass is not only resistant to high temperature, but also acid, corrosion and electrical insulation.

04-Common Standards:

|

Description |

Thickness |

Max. Size(mm) |

Heat of impact |

Application |

|

Tempered Glass |

3-25mm |

1800*2400 |

0 ≤ 350ºC |

Lamp, Buried lights All kinds of viewing window |

|

Glass |

2-30mm |

1500*450 |

0 ≤ 660ºC |

Boller,Pressur vessel, Micro overn panel High temperature light, Spotlight panel, |

|

Ceramic Glass |

3-5mm |

1100* 850 |

660 ≤ 850 ºC |

Fireplace, micro oven screen, induction cooker panel,ect |

|

Super hight temperature glas |

1-150mm |

500*500 |

850 ≤ 1730 ºC |

All kinds of high temperaturer place are over 900 ºC |

05-Technical parameters of high borosilicate glass:

|

Silica content |

>80% |

Density (20 º C) |

2.23gcm-1 |

|

Stain point |

520 º C |

Thermal capacity ( 20-100 º C ) |

0.82KJ* ( kg*k ) -1 |

|

Annealing temperature |

560 º C |

Thermal conductivity |

1.2W*(m*k) -1 |

|

Soften point |

820 º C |

Thermal shock resistance |

180 K |

|

Refractive index |

1.47 |

Max. working temperature |

750 º C (long time) |

|

Transparency (2mm) |

92% |

Refractive index |

1.47384 |

|

Processed point (104dpas) |

1220 º C |

Thermal expansion coefficient (0-300 º C) |

3.3 +_0.1*10 -6 K -1

|

|

Thickness |

2-15mm |

Max size |

1500*1000mm |

Borosilicate glass/high borosilicate glass/tempered borosilicate glass/borosilicate glass plate/borosilicate glass

06-Application :

Borosilicate glass/high borosilicate glass/tempered borosilicate glass/borosilicate glass plate/borosilicate glass 3.3 were widely used in follow field:

(1) Mechanical Components, Environmental Protection Industry,

(2) Plasma Processing Apparatus

(3)Aerospace, Commercial Industrial

(4) Military, Defense, Electronics

(5) Instrumentation, Research & Development, Nuclear

(6)Optical, Medical, Oil & Gas Lighting, Laser Equipment Security

(7) Automotive, Audio/Video, Display Technology

(8) Furniture Design, Lighting Technology

(9) Military Technology, Office Automation, Projection Technology

(10) Vandal Proof Systems, Semiconductor, High Temperature Lighting

(11) Fiber Optics,etc.