- Product Details

- {{item.text}}

Quick Details

-

MF:

-

SiO2

-

EINECS No.:

-

231-545-4

-

Place of Origin:

-

Liaoning, China

-

Type:

-

Fumed white carbon black

-

Brand Name:

-

Fusil

-

Model Number:

-

Fusil 380

-

Specific Surface Area BET(m2/g):

-

110±20; 200+-15; 380+-20

-

pH Value in 4% dispersion:

-

3.8-4.2

-

Loss on Drying 2h@ 105℃(%):

-

≤1.5

-

Loss on Ignition 2h@ 1000℃(%):

-

≤2.0

-

Fe2O3 (mg/kg):

-

≤0.003

-

AL2O3 (mg/kg):

-

≤0.002

-

Chloride (mg/kg):

-

≤0.0056

-

Bulk Density (g/l):

-

40-60

-

SiO2 Content(%):

-

>=99.8%

-

Surface Treatment:

-

No

Quick Details

-

CAS No.:

-

7631-86-9

-

Purity:

-

>=99.8%

-

Other Names:

-

Silicon Dioxide

-

MF:

-

SiO2

-

EINECS No.:

-

231-545-4

-

Place of Origin:

-

Liaoning, China

-

Type:

-

Fumed white carbon black

-

Brand Name:

-

Fusil

-

Model Number:

-

Fusil 380

-

Specific Surface Area BET(m2/g):

-

110±20; 200+-15; 380+-20

-

pH Value in 4% dispersion:

-

3.8-4.2

-

Loss on Drying 2h@ 105℃(%):

-

≤1.5

-

Loss on Ignition 2h@ 1000℃(%):

-

≤2.0

-

Fe2O3 (mg/kg):

-

≤0.003

-

AL2O3 (mg/kg):

-

≤0.002

-

Chloride (mg/kg):

-

≤0.0056

-

Bulk Density (g/l):

-

40-60

-

SiO2 Content(%):

-

>=99.8%

-

Surface Treatment:

-

No

Superfine NM Grade Silica Rubber Granule Silicon Rubber Sheet SiO2 99% Powder

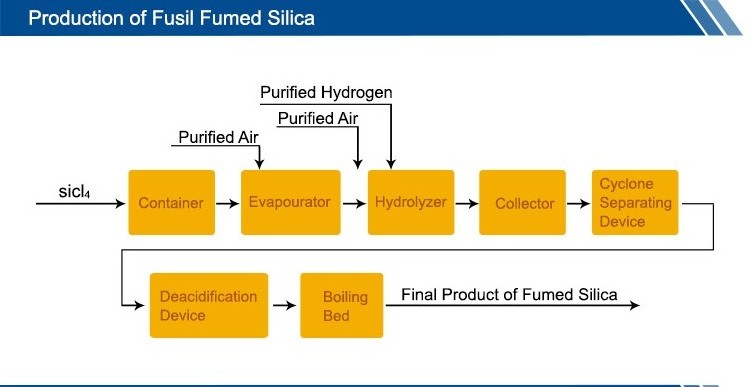

Products Description

Fumed silica is the superfine micro-nano fine chemical product, which is divided into hydrophilic type and hydrophobic type in accordance with their different surface treatments.

Its appearance is white powder. Native particle size ranges from 5nm-40nm, with significant functions of thixotropy, reinforcing, thickening and filling. Therefore, it is widely used in the industries of rubber, sealant, plastic, resin, paint, printing ink, papermaking, medicine, cosmetics, food etc.

Its appearance is white powder. Native particle size ranges from 5nm-40nm, with significant functions of thixotropy, reinforcing, thickening and filling. Therefore, it is widely used in the industries of rubber, sealant, plastic, resin, paint, printing ink, papermaking, medicine, cosmetics, food etc.

Specification

|

Grade

|

Fusil 380

|

Fusil 150

|

Fusil 200

|

Fusil 200P

|

Fusil 200V

|

Fusil 300

|

|||||

|

Form

|

White Power

|

White Power

|

White Power

|

White Power

|

White Power

|

White Power

|

|||||

|

BET surface Area m2/g

|

380±20

|

150±10

|

200±15

|

200±25

|

200±15

|

300±20

|

|||||

|

PH value

|

3.8-4.2

|

3.8-4.2

|

|

3.6-4.3

|

3.6-4.3

|

3.8-4.2

|

|||||

|

Heating loss(105℃,2h) wt%

|

≤1.5

|

≤1.5

|

≤1.5

|

≤1.5

|

≤1.5

|

≤1.5

|

|||||

|

Ignition loss (1000℃,2h) wt%

|

≤2

|

≤2

|

≤2

|

≤2

|

≤2

|

≤2

|

|||||

|

SiO2 content (%)

|

≥99.8

|

≥99.99

|

≥99.99

|

≥99.99

|

≥99.99

|

≥99.99

|

|||||

|

Bulk Density (g/l)

|

40-60

|

40-60

|

40-60

|

40-60

|

40-60

|

40-60

|

|||||

|

Equivalent Grade

|

DEGUSSA

|

Aerosil 380

|

Aerosil 150

|

Aerosil 200

|

Aerosil 200P

|

Aerosil 200

|

Aerosil 300

|

|

|

CABOT

|

EH-5

|

LM-150

LM-150D

|

M-5

M-7D

|

M-5P

|

M-5

M-7D

|

H-5

|

|

|

WACKER

|

T40

|

V15

V15A

|

N20

|

N20P

|

N20

|

T30

|

|

|

YOKYYAMA

|

QS40

|

QS10

|

QS102

|

/

|

QS102

|

QS30

|

|

|

OIC

|

K400

|

K150

|

K200

|

/

|

K200

|

K300

|

Products Application

* Adsorbent and carrier

* Ink-jet printing coating

* Senior dental material filler

* Catalyst carrier, significant thermal insulation, used in low temperature and high temperature insulation.

* Ink-jet printing coating

* Senior dental material filler

* Catalyst carrier, significant thermal insulation, used in low temperature and high temperature insulation.

|

Application

|

|

Primary Performance Criteria

|

Suggest Grade

|

Suggest Addition (%)

|

|

|

Rubber / Synthetic Rubber

|

|

Reinforcement

|

Fusil 200, Fusil 200V, Fusil 380

|

5.0-30

|

|

|

Pharmaceutical

|

|

Thickening; Thixotropy; Anti-settling;

|

Fusil 200P

|

1.0-5.0

|

|

|

HTV Silicone Rubber

|

|

Reinforcement; Elongation Resistance; Ease of Compounding

|

Fusil 150, Fusil 200, Fusil 200V, Fusil 300, Fusil 380

|

15-50

|

|

|

RTV Silicone Rubber

|

RTV-silicone sealant (1 component)

|

Reinforcement; Thixotropy, Rheology control, dispersability

|

Fusil 150, Fusil 200, Fusil 200V, Fusil 300, Fusil 380

|

3.0-30

|

|

|

|

RTV-molding compound

|

|

|

3.0-30

|

|

|

|

Liquid Silicone Rubber

|

|

|

15-35

|

|

|

Adhesive

|

Polychloroprene

|

Thickening; Thixotropy; Anti-settling; Sag Resistance; Extrusion Rate; Rheology Control

|

Fusil 200, Fusil 200V

|

1.0-2.0

|

|

|

|

Extrusion Rate

|

|

|

|

|

|

|

Latex

|

|

|

|

|

|

PVC

|

Plastisol

|

Thickening; Thixotropy; Anti-settling; Free-flow; Insulation

|

Fusil 200

|

0.3-2.5

|

|

|

|

Organosol

|

|

|

|

|

|

|

Plastisol PVC Mixture

|

|

|

0.1-1

|

|

|

|

Cable Compound

|

|

|

1.0-2.0

|

|

|

|

Membrane

|

|

|

0.1-1

|

|

|

Unsaturated Polyester Resin

|

Laminating Resin

|

Thickening; Thixotropy; Anti-settling;

|

Fusil 200,Fusil 300, Fusil 380

|

0.8~1.5

|

|

|

|

Gel coating

|

|

|

2.0-3.0

|

|

|

|

Grouting mixture

|

|

|

0.5-2.0

|

|

|

Print Ink

|

Relief Printing

|

Thickening; Thixotropy; Anti-settling; Sag Resistance; Rheology Control

|

Fusil 200, Fusil 300, Fusil 380

|

0.5-2.0

|

|

|

|

Intaglio Printing

|

|

|

|

|

|

|

Hectograph

|

|

Fusil 150, Fusil 200, Fusil 300,Fusil 380

|

0.5~2.5

|

|

|

Insulating Glue

|

|

Thickening; Thixotropy;

|

Fusil 200, Fusil 200V

|

5.0-10

|

|

Product packaging

Hot Searches