The flotation is widely used in mineral dressing. According to statistics, more than 90 % of non-ferrous metals are flotation processes.

In addition, it is also used for the processing of black metals, precious metals, and non-metallic minerals, and even in the field of water purification in recent years.

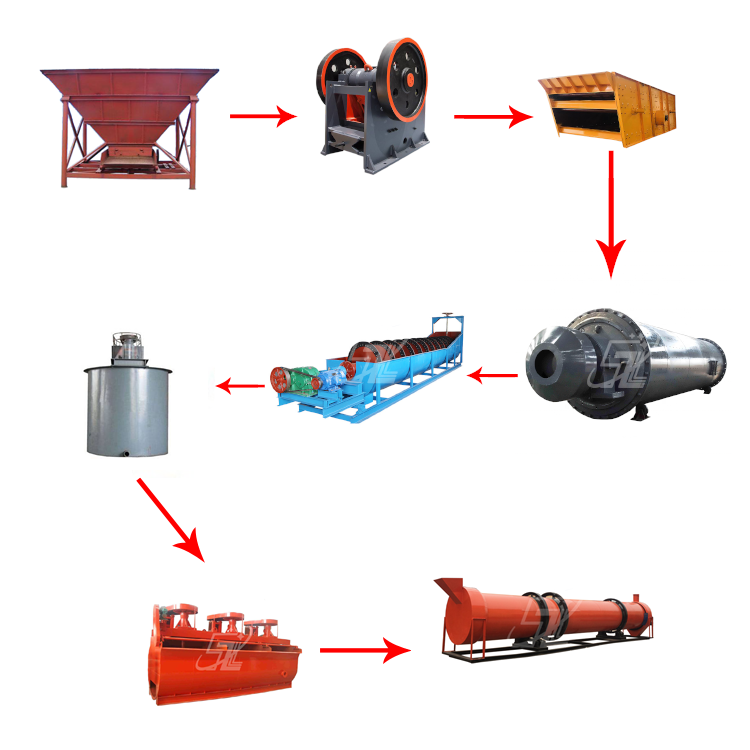

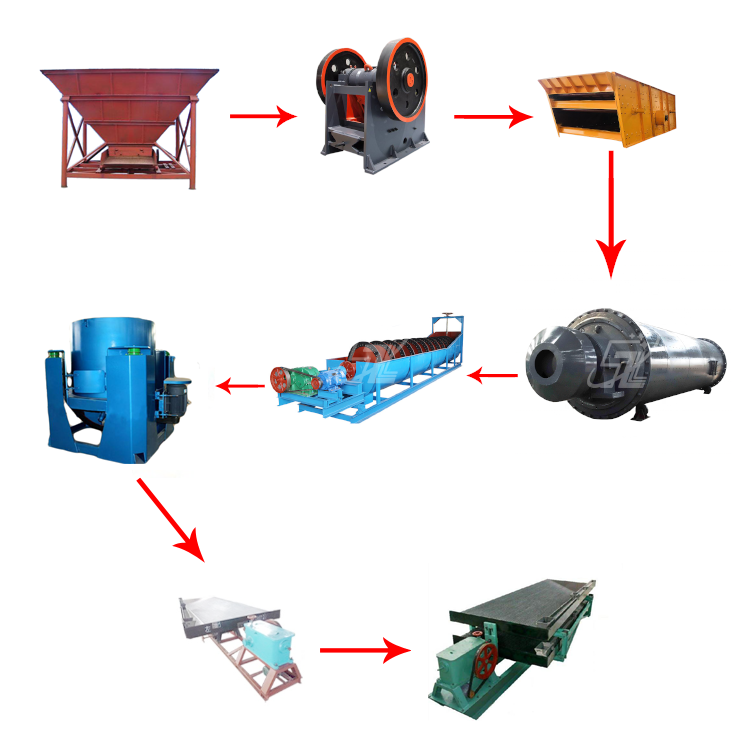

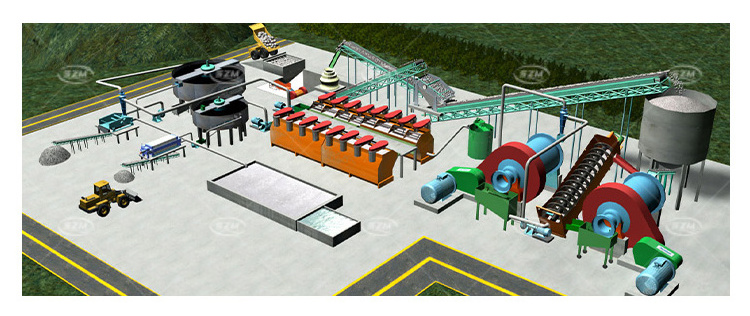

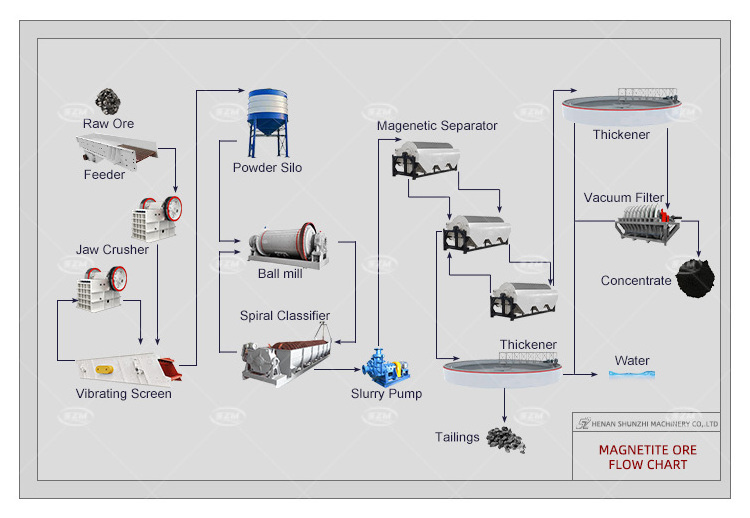

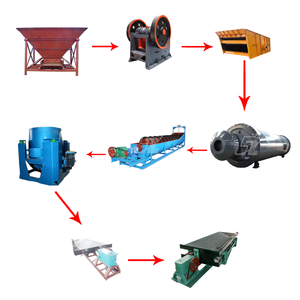

It mainly contains four part of the beneficiation area. The crushing stage, the grinding and separating stage, and the mixing and flotation stage, filtering and drying.

The crushing stage:

PE series crusher to crush the run-ore into small block, working at 8-10 hours one day. The crushed material is transported by belt conveyor to next stage, usually the ore store in storage for grinding. We hold the more crush less grinding to prolong the service time of the Ball mill. Also the capacity will extend the design ability.

The grinding and separating stage:

The Ball mill’s working atmosphere is wet, the water and crushed material will be grinded in the Ball mill, the spiral classifier with Ball mill makes a closed circuit, after spiral classifier’s classifying, the relatively big granularity will flow back to Ball mill, and standard size (120 mesh) will go to agitation tank and flotation machine for separating. This stage works for 24 hours in three shifts. The spiral classifier can be replaced by cyclone. The spiral classifier is more durable.

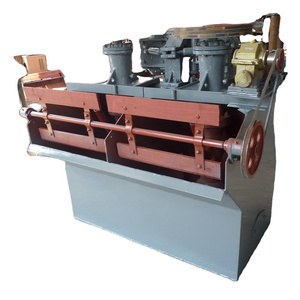

The mixing and flotation stage:

The slurry after treatment will go to the flotation machine for further separating. The slurry flow to the agitation tank to mix the chemicals and the in the flotation machine, the metal will attach on the bubbles, and bring by the scraper. It works for 24 hours in three shifts.

The filtering and drying stage:

After flotation machine, the concentrate slurry send to the thickener, and then the filter.After filter the moisture is about 30%, and then use the rotary dryer to remove the moisture.