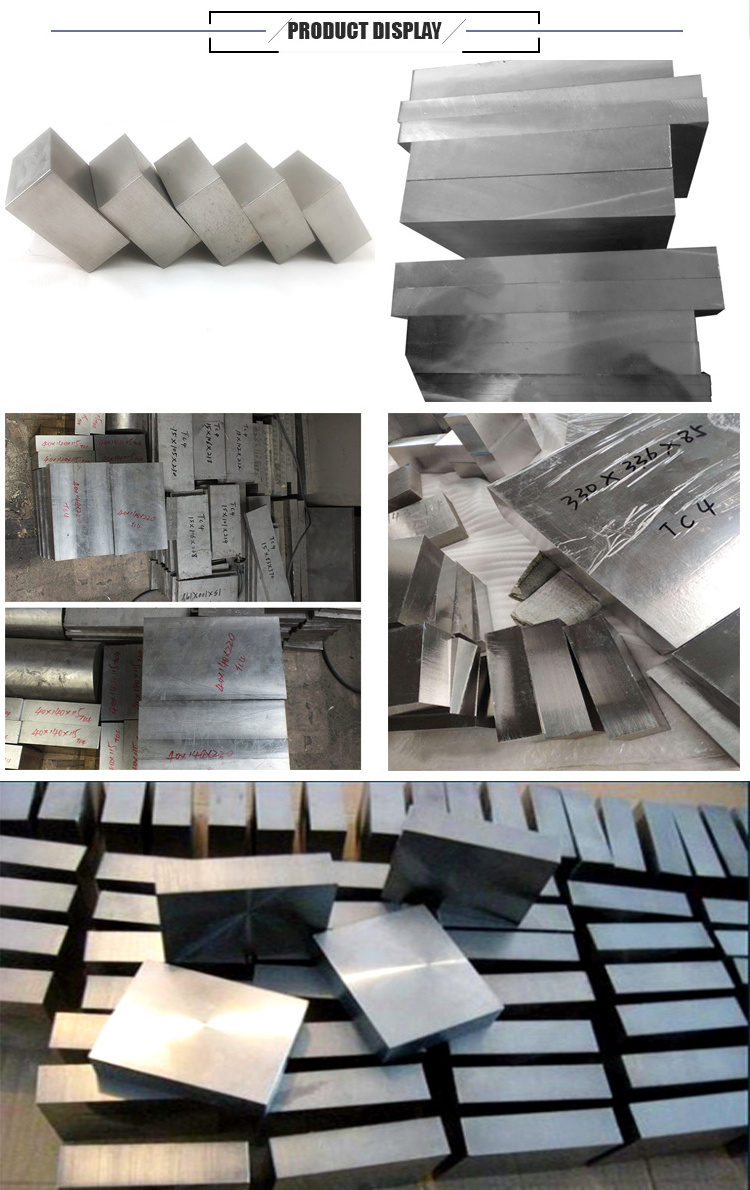

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

JYM

-

Model Number:

-

titanium block

-

Application:

-

industrial chemical medical

-

Technique:

-

sintering/rotary swaging

-

Grade:

-

titanium

-

Color:

-

Primary colors

-

Density:

-

about 4.51g/cm3

-

Technology:

-

sintering/rotary swaging

-

Material:

-

Gr1 Gr2 Gr3 Gr4 Gr5 Gr7 Gr5ELI

-

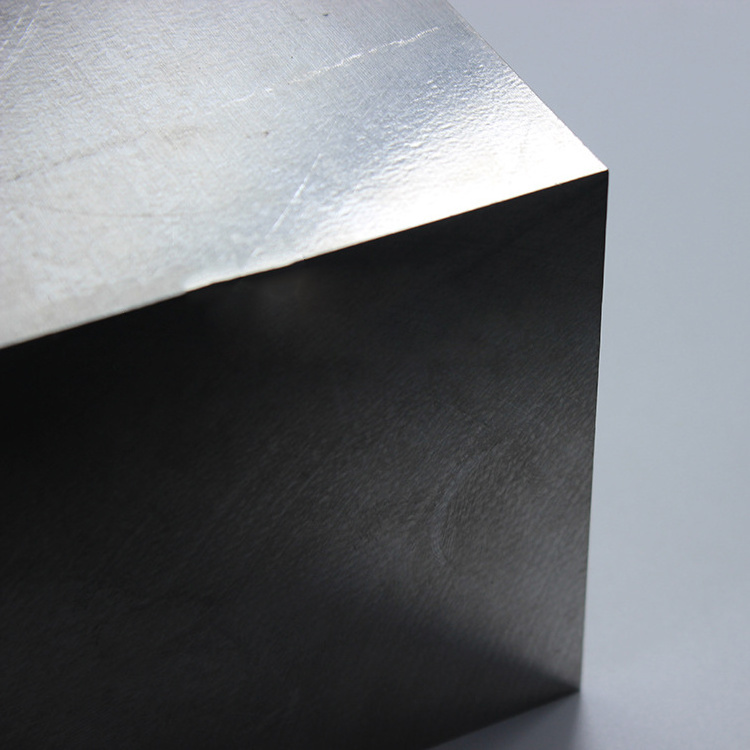

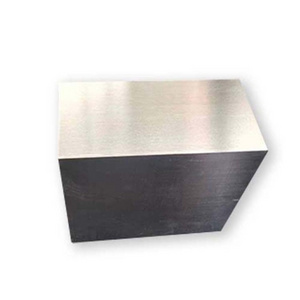

Surface:

-

polishing

-

Certificate:

-

ISO9001:2008

-

Shape:

-

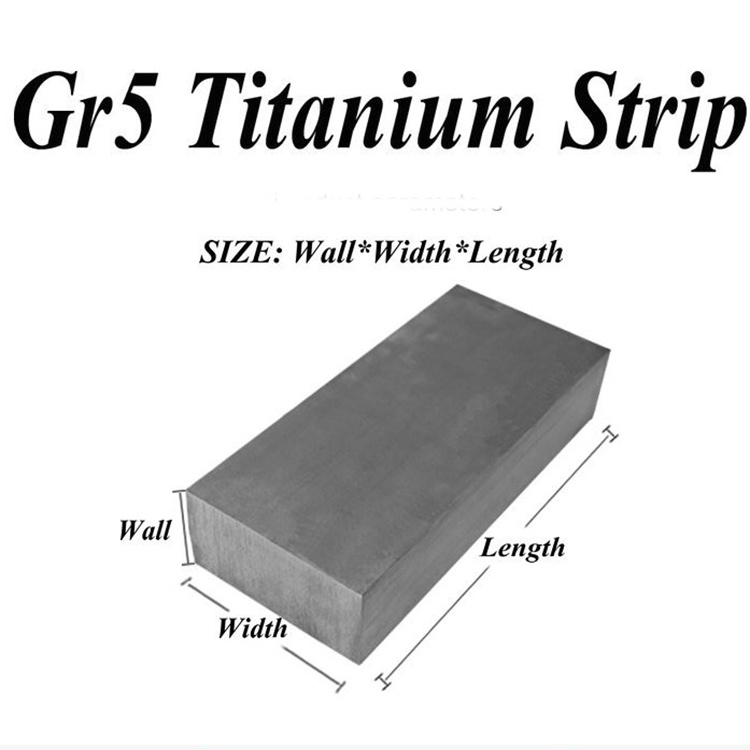

Titanium foil strip/titanium sheets plate/titanium coil

-

condition:

-

vacuum annealing/temper/quench

-

Advantage:

-

Corrosion resistance, high strength, light quality.

-

Product Name:

-

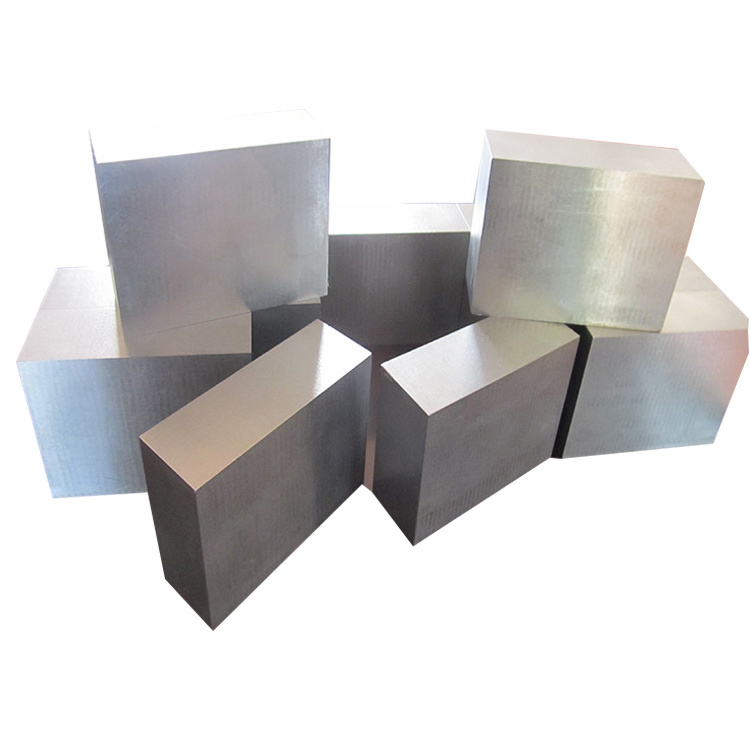

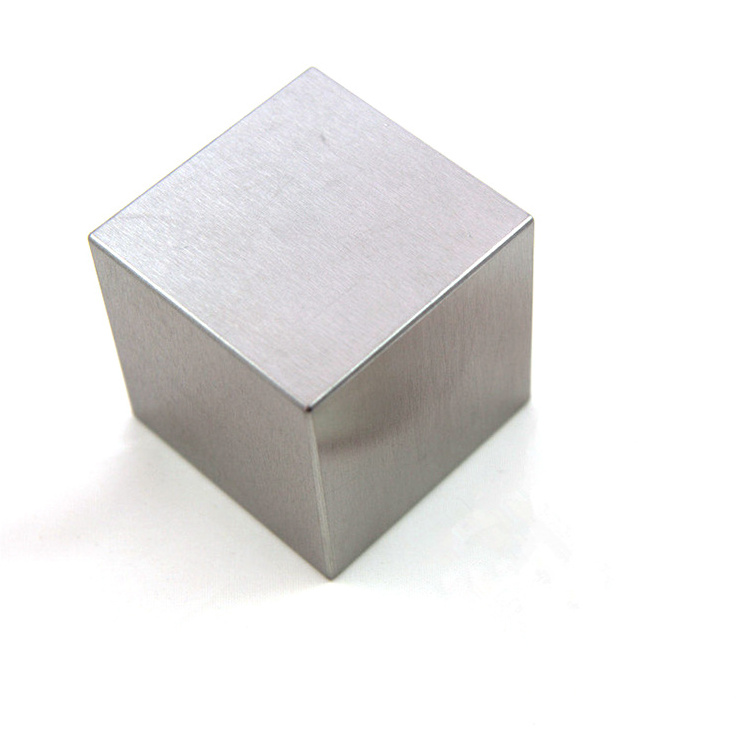

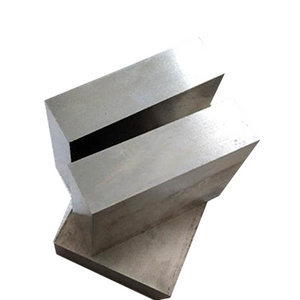

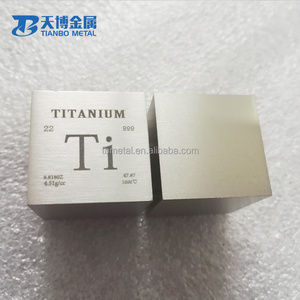

Customized Titanium Ti 6al 4v Block

Quick Details

-

Powder Or Not:

-

Not Powder

-

Ti Content (%):

-

>= 99.96%

-

Place of Origin:

-

Shaanxi, China

-

Brand Name:

-

JYM

-

Model Number:

-

titanium block

-

Application:

-

industrial chemical medical

-

Technique:

-

sintering/rotary swaging

-

Grade:

-

titanium

-

Color:

-

Primary colors

-

Density:

-

about 4.51g/cm3

-

Technology:

-

sintering/rotary swaging

-

Material:

-

Gr1 Gr2 Gr3 Gr4 Gr5 Gr7 Gr5ELI

-

Surface:

-

polishing

-

Certificate:

-

ISO9001:2008

-

Shape:

-

Titanium foil strip/titanium sheets plate/titanium coil

-

condition:

-

vacuum annealing/temper/quench

-

Advantage:

-

Corrosion resistance, high strength, light quality.

-

Product Name:

-

Customized Titanium Ti 6al 4v Block

| Description | Titanium block/ingot/billet |

| Material | Gr1 Gr2 Gr3 Gr4 Gr5 Gr6 Gr7 Gr9 Gr11 Gr12 Gr23 Ti15333 BT1-00 BT1-0 BT1-2 |

| Standard | ASTM B381,ASTM F67,ASTW F136 |

| Size | customed |

| MOQ | 1kg |

| Property | high strength fine corrosion resistance low density and low weight |

| Tehnique | Forging ,Machining |

| Application |

1. Low Density and High Specification Strength

2. Excellent Corrosion Resistance

6. Good Thermal Properties 7. Low Modulus of Elasticity |

Titanium Block Chemical Requirements:

|

|

N |

C |

H |

Fe |

O |

Al |

V |

Pa |

Mo |

Ni |

Ti |

|

Gr 1 |

0.03 |

0.08 |

0.015 |

0.20 |

0.18 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 2 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 3 |

0.05 |

0.08 |

0.015 |

0.30 |

0.35 |

/ |

/ |

/ |

/ |

/ |

bal |

|

Gr 4 |

0.05 |

0.08 |

0.015 |

0.50 |

0.40 |

/ |

/ |

/ |

/ |

/ |

|

|

Gr 5 |

0.05 |

0.08 |

0.015 |

0.40 |

0.20 |

5.5~6.75 |

3.5~4.5 |

/ |

/ |

/ |

bal |

|

Gr 7 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

0.12~0.25 |

/ |

/ |

bal |

|

Gr 9 |

0.03 |

0.08 |

0.015 |

0.25 |

0.15 |

2.5~3.5 |

2.0~3.0 |

/ |

/ |

/ |

bal |

|

Gr12 |

0.03 |

0.08 |

0.015 |

0.30 |

0.25 |

/ |

/ |

/ |

0.2~0.4 |

0.6~0.9 |

bal |

Titanium Block Tensile Requirements :

|

grade |

Tensil strength(min) |

Yeild strength(min) |

Elongation(%) |

||

|

ksi |

MPa |

ksi |

MPa |

||

|

1 |

35 |

240 |

20 |

138 |

24 |

|

2 |

50 |

345 |

40 |

275 |

20 |

|

3 |

65 |

450 |

55 |

380 |

18 |

|

4 |

80 |

550 |

70 |

483 |

15 |

|

5 |

130 |

895 |

120 |

828 |

10 |

|

7 |

50 |

345 |

40 |

275 |

20 |

|

9 |

90 |

620 |

70 |

438 |

15 |

|

12 |

70 |

438 |

50 |

345 |

18 |

Titanium Block Production Specifications:

|

Processing |

Sizes |

||

|

Thickness (mm) |

Width (mm) |

Length (mm) |

|

|

Hot Rolling |

>4.75 - 60.0 |

400 -3000 |

1000 - 10000 |

|

Cold Rolling |

0.30 - 6 |

400 - 2000 |

1000 - Max |