Note:

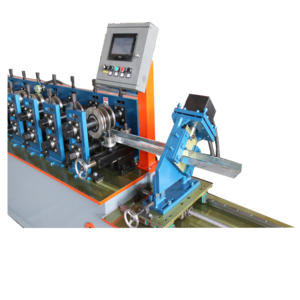

4)There is hand wheel on the feeding part, easy for you adjust the feeding size when produce different sizes of products

5)There is also guiding device, easy for the material go into the machine smoothly and quickly.

6)Please check the yellow box, there is oil drip device on the feeding part, it can make oils on the products, in case the finished studs are rust.

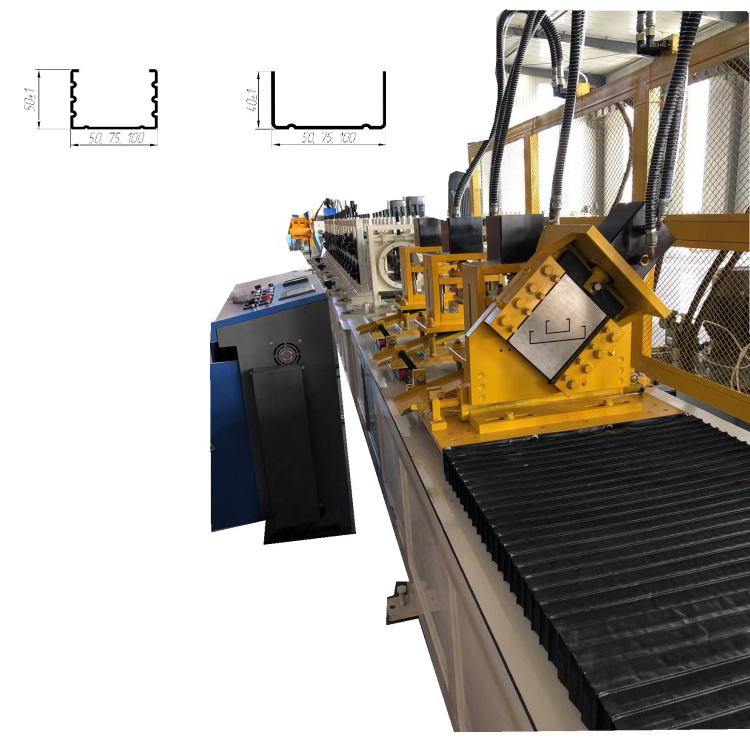

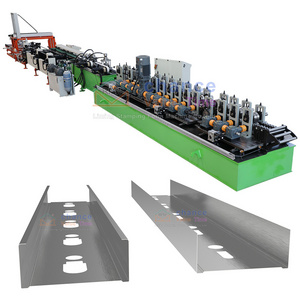

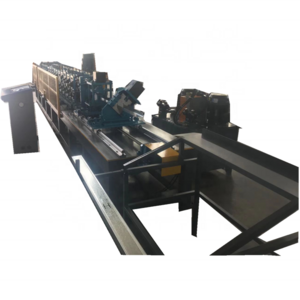

We use split rollers to realize one machine to produce different sizes of drywall studs, you can adjust the size automatically by PLC

Rolling shaft Shaft material: 45# steel Shaft diameter: 50.8 mm Tempering treatment Roller Roller material: Cr12 Quenched

treatment Rolling station number:17 stations Work speed:0-70 m/min(without knurling) 0-60m/min(with knurling) Machine frame:Base

use high quality H steel;Vertical iron arch casting frame structure. Bearing:Chinese famous brand Harbin ( high quality) Work

power:7.5 kw+11kw Transmission:By Gear box