CGI is lightweight and easily transported. It was and still is widely used especially in rural and military buildings such as sheds and water tanks. Its unique properties were used in the development of countries like Australia from the 1840s, and it is still helping developing countries today.

Corrugated iron is equivalent to tin roof.

- Product Details

- {{item.text}}

Quick Details

-

Width:

-

600mm-1250mm

-

Length:

-

1000-12000mm

-

Delivery Time:

-

15-21days

Quick Details

-

Grade:

-

DX51D/SGCC

-

Tolerance:

-

±10%

-

Place of Origin:

-

China

-

Width:

-

600mm-1250mm

-

Length:

-

1000-12000mm

-

Delivery Time:

-

15-21days

Product Description

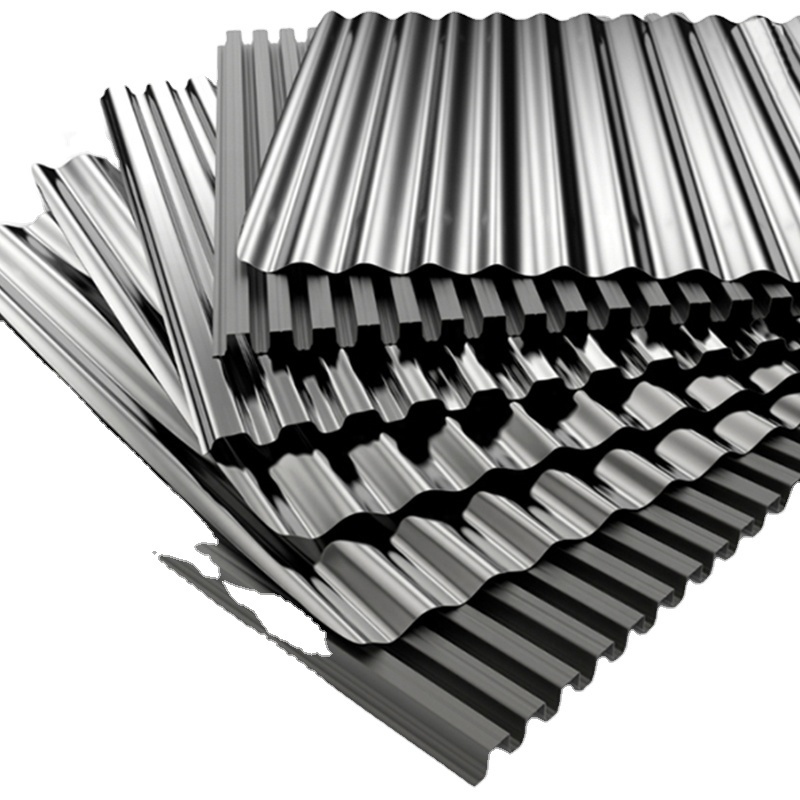

Cold rolled CGI corrugated galvanized steel

Corrugated galvanized iron or steel (colloquially corrugated iron (near universal), wriggly tin (taken from UK military slang),

pailing (in Caribbean English), corrugated sheet metal (in North America) and occasionally abbreviated CGI) is a building material composed of sheets of hot-dip galvanized mild steel, cold-rolled to produce a linear corrugated pattern in them. The corrugations increase the bending strength of the sheet in the direction perpendicular to the corrugations, but not parallel to them. Normally each sheet is manufactured longer in its strong direction.

pailing (in Caribbean English), corrugated sheet metal (in North America) and occasionally abbreviated CGI) is a building material composed of sheets of hot-dip galvanized mild steel, cold-rolled to produce a linear corrugated pattern in them. The corrugations increase the bending strength of the sheet in the direction perpendicular to the corrugations, but not parallel to them. Normally each sheet is manufactured longer in its strong direction.

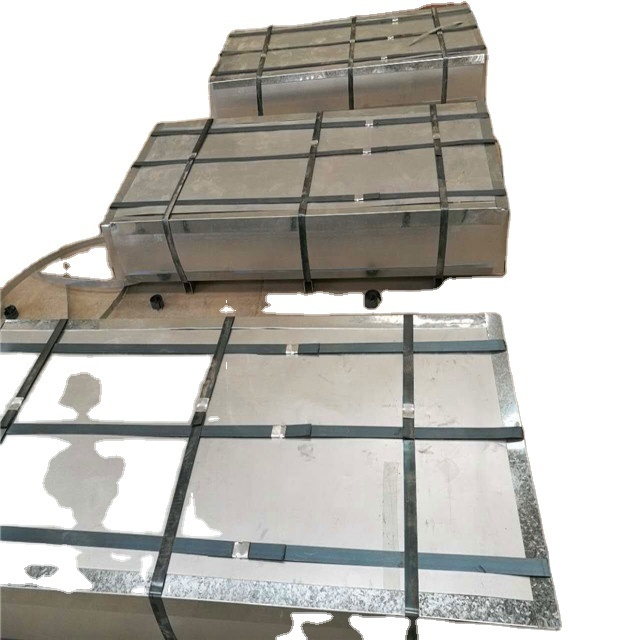

Hot-dip galvanization is a form of galvanization. It is the process of coating iron and steel with zinc, which alloys with the surface of the base metal when immersing the metal in a bath of molten zinc at a temperature of around 840 °F (449 °C).

Galvanized steel is widely used in applications where corrosion resistance is needed without the cost of stainless steel, and is considered superior in terms of cost and life-cycle. It can be identified by the crystallization patterning on the surface.

Specification

|

Corrugated Galvanized Roofing Sheet

|

|

|

|

|||

|

Material

|

SGCC, SGCH, JIS G3302, DX51D, DX52D, DX53D

|

|

|

|||

|

Thickness

|

0.10 - 1mm or as customer's requirement

|

|

|

|||

|

Width

|

600 - 1250mm or as customer's requirement

|

|

|

|||

|

Length

|

2 - 5 meters

|

|

|

|||

|

Tolerance

|

Thickness:+/- 0.02mm Width:+/-2mm

|

|

|

|||

|

Zinc Coating

|

30 - 275g/m2

|

|

|

|||

|

Surface Treatment

|

unoil, dry, chromate passivated, non-chromate passivated

|

|

|

|||

|

Certification

|

ISO 9001-2008, SGS, CE, BV

|

|

|

|||

|

Technique

|

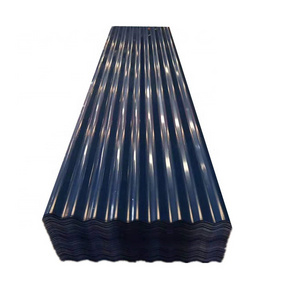

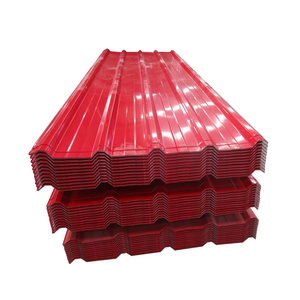

Cold rolled->hot dipped galvanizing->Color Coated -> corrugated

|

|

|

|||

|

Depth of corrugated

|

from 15mm to 18mm

|

|

|

|||

|

Pitch

|

from 75mm to 78mm

|

|

|

|||

|

Gloss

|

The gloss can changeable by Customers' Request.we can also do some High gloss.

|

|

|

|||

|

Standard

|

GB/T 12754-2006; ASTM A 755; EN 10169; JIS G 3312; AISI; BS; DIN

|

|

|

|||

|

Grade

|

CGCC/SGCC/SGCH/SPCC

|

|

|

|||

|

Yield Strength

|

550MPA/As required

|

|

|

|||

|

Tensile strength

|

600MPA/As required

|

|

|

|||

|

Hardness

|

Full hard/soft/As required

|

|

|

|||

|

Application

|

various roofs or walls referring to the large size factory buildings, storages, exhibition halls, gymnasiums etc.

|

|

|

|||

Hot Searches