- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

China

-

Dimension(L*W*H):

-

4200mm*1700mm*2000mm

-

Weight:

-

3500kg

-

Name:

-

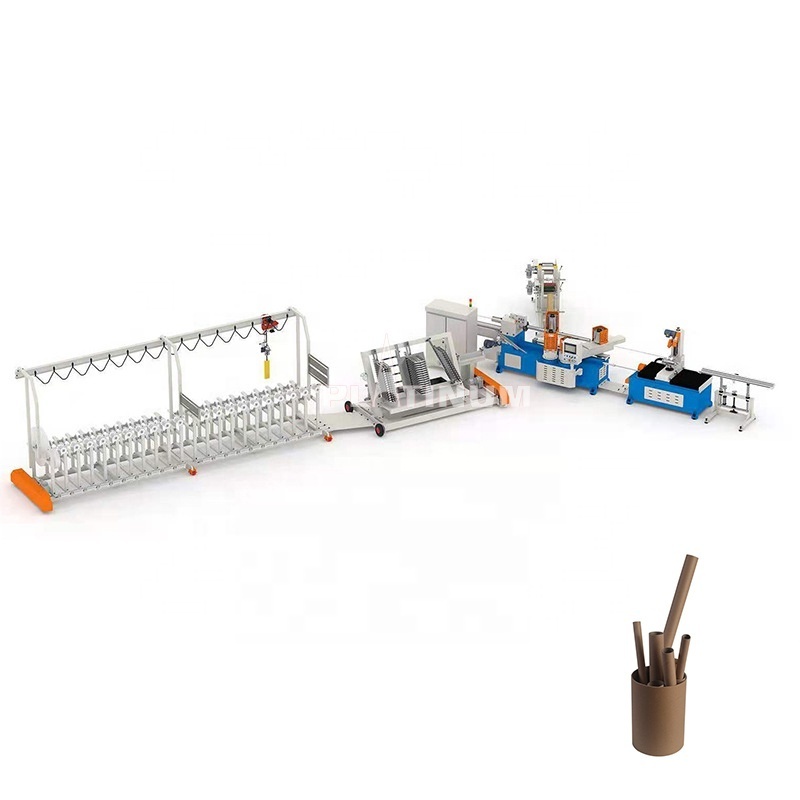

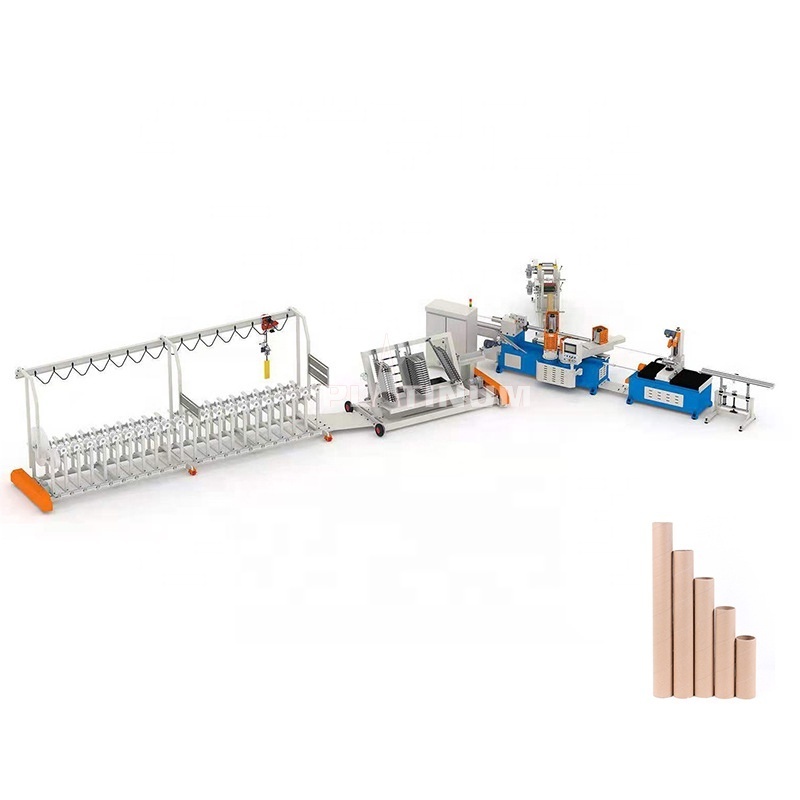

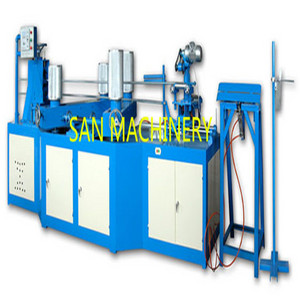

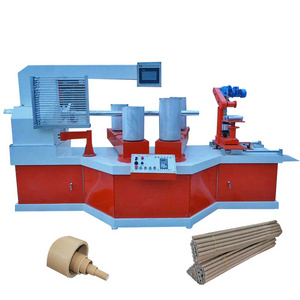

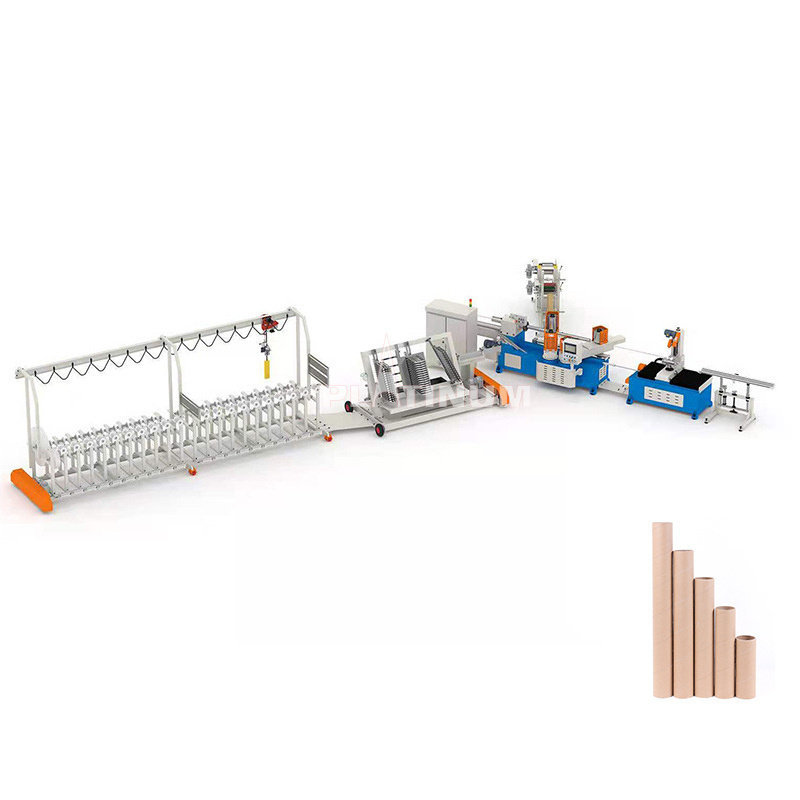

Paper Tube Making Machine

-

Finished Products:

-

Paper core

-

Function:

-

paper tube forming

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Free spare parts, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support

Quick Details

-

Type:

-

paper tube making machine

-

Production Capacity:

-

3-20m/min

-

Max. workable width:

-

Other

-

Place of Origin:

-

China

-

Dimension(L*W*H):

-

4200mm*1700mm*2000mm

-

Weight:

-

3500kg

-

Name:

-

Paper Tube Making Machine

-

Finished Products:

-

Paper core

-

Function:

-

paper tube forming

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Free spare parts, Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Online support

Product Description

The paper tube produced by the paper tube machine is used in various industries, such as chemical fiber industry tube, film industry tube, printing industry tube, paper industry tube, leather industry tube, food packaging tube, construction industry tube, exhibition industry Use tubes and so on. There are also many types of paper tube machines. The most common paper tube machines are spiral paper tube machines and flat roll paper tube machines.

Features:

1. The main body is made of thick and heavy steel plate after CNC cutting and welding, the frame is stable and not easy to deform, and the vibration is small.

2. The main drive adopts hard-toothed full oil bath gear for speed reduction, low noise, low heatgeneration, high speed and large torque.

3. The main motor adopts vector type high torque frequency converter for speedregulation.

4. Equipped with hydraulic belt tensioning device, belt tension sensor, and belt angle sensor, which can automatically

adjust the belt tension and angle.

adjust the belt tension and angle.

5. Equipped with a CNC synchronous follow-up shear system, and the cutting table is driven by a precision ball screw and a high-performance servo motor.

6. Equipped with pulse fixed-length control and feed-forward compensatio function to ensure the same cutting length under different host operating speeds.

7. Double PLC control system is adopted, IO output control and functional operation are controlled separately, which improves the cutting response speed, and the cutting length control is more accurate than before.

8. Equipped with a new type of operation panel and large-size color touch screen man-machine interface operation.

Specification

|

Number of winding paper layers

|

3-16 layers

|

|

Maximum coil diameter

|

200mm

|

|

Minimum coil diameter

|

20mm

|

|

Maximum coil thickness

|

10mm

|

|

Minimum coil thickness

|

0.5mm

|

|

Fixing method of core mold

|

Flange tightening

|

|

Winding head

|

Four-head single belt

|

|

Cutting method

|

Single round knife cutting without resistance

|

|

Gluing method

|

Double-sided glue

|

|

Fixed length method

|

Encoder (optional for photoelectric positioning)

|

|

Number of operators

|

1-2 people

|

|

Roll out paper tube speed

|

3-20m/min

|

|

Speed control

|

Frequency converter

|

|

Power

|

380v

|

|

Machine size

|

4200mm*1700mm*2000mm

|

|

Land area

|

18000mm*6000mm

|

|

Rim diameter

|

215mm

|

|

Rim height

|

200mm/350mm

|

|

Minimum track

|

750mm

|

|

Maximum track

|

950mm

|

|

Weight

|

3500kg

|

Product packaging

Packaging:

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like

to have seamless cooperation with your forwarder at your convenience.

Stable wooden package protects machine from strike and damage.

Wound plastic film keeps machine out of damp and corrosion.

Fumigation-free package helps the smooth customs clearance.

The big size machine will be fixed in container without package.

Shipping:

For LCL, we cooperated with reputable logistics team to send machine to sea port speedily and safely.

For FCL, we get the container and do container loading by our skillful workers carefully.

For forwarders, we have professional and long-term cooperated forwarders who can handle the shipment smoothly. Also we would like

to have seamless cooperation with your forwarder at your convenience.

Hot Searches