- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ENWEI

-

Voltage:

-

220

-

Gradeability:

-

14°

-

Rated power:

-

55kw

-

Overall size, traveling:

-

5280*2140*2650 mm

-

Rotating speed:

-

≥10 r/min

-

Max. dumping height:

-

≥3500 mm

-

Max. vertical wall digging depth:

-

≥2600mm

-

Max. traction:

-

70 Kn

-

Min. turning radius, front part:

-

≤1500 mm

-

Turning radius, rear part:

-

1300 mm

-

Certification:

-

CE

Quick Details

-

Power:

-

70 KW

-

Warranty:

-

1 Year

-

Width or Diameter:

-

less than 3000mm

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ENWEI

-

Voltage:

-

220

-

Gradeability:

-

14°

-

Rated power:

-

55kw

-

Overall size, traveling:

-

5280*2140*2650 mm

-

Rotating speed:

-

≥10 r/min

-

Max. dumping height:

-

≥3500 mm

-

Max. vertical wall digging depth:

-

≥2600mm

-

Max. traction:

-

70 Kn

-

Min. turning radius, front part:

-

≤1500 mm

-

Turning radius, rear part:

-

1300 mm

-

Certification:

-

CE

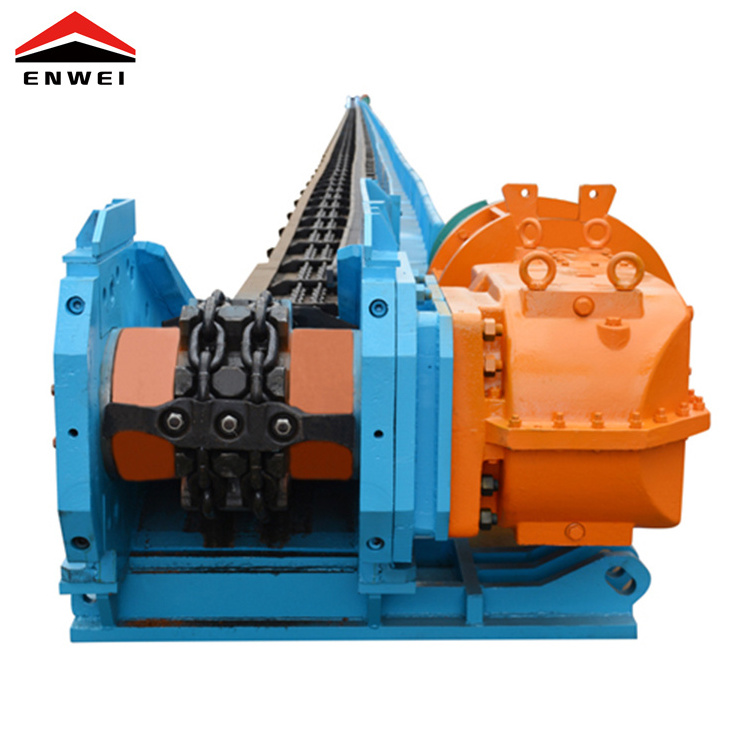

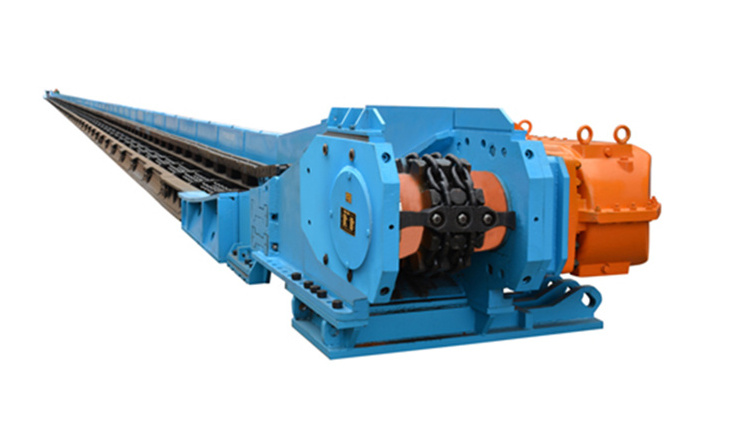

Products Description

It is used to convey coal, powder, granular or lumpy bulk materials widely in the industries of power stations, coal preparation plants, ports, mines, metallurgy, and chemical industry, gives first place to horizontal conveyance, and second to inclined conveyance, with the maximal inclination of 20 degrees. It has simple structure for achieving single or double layer or bidirectional conveying, convenient installation and maintenance, and multipoint loading and unloading, where in the maximum conveying length is 150m, its tank is lined with plates which commonly are cast stone or wear resistant steel plates. The heavy

scraper conveyor features advanced technology, strong power, large conveying capacity and excellent sealing property, also can be custom-made as required.

Features

1. Long time of warranty.

2. Full-closed,wear resistance structure.

3. Horizontal & whole inclined transport of bulk material.

Operating Principle

When scraper conveyor is conveying materials, the pressure which comes from the chains in conveying direction of materials and the weight function of materials themselves cause the internal friction.This friction assures the stable condition between material layers, and it can overcome the external frictional which caused by moving materials in the trough, then make the materials to form a continuous whole flow to be transported.

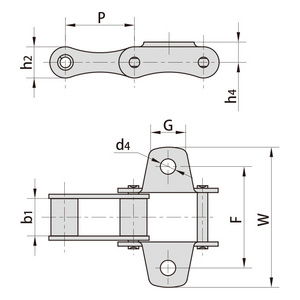

Special component

1. Scraper chain: alloy steel wear resistance forged links with carburizing heat treatment.

2. Head section: The head wheel is made of wheel hubs and head gear plate,head gear plate is made of alloy steel with quench heat treatment and has strong wear resistance.

3. Middle section: The rectangular closed case with upper and lower wear rail guides inside, the material is 65Mn or 60Si2Mn with heat treatment;the plate thickness of bottom and side plate is over 10mm, it can be customized.

4. Tail section: It has tension devices both sides to adjust the length of chains, to avoid the accident due to chain elongation.

scraper conveyor features advanced technology, strong power, large conveying capacity and excellent sealing property, also can be custom-made as required.

Features

1. Long time of warranty.

2. Full-closed,wear resistance structure.

3. Horizontal & whole inclined transport of bulk material.

Operating Principle

When scraper conveyor is conveying materials, the pressure which comes from the chains in conveying direction of materials and the weight function of materials themselves cause the internal friction.This friction assures the stable condition between material layers, and it can overcome the external frictional which caused by moving materials in the trough, then make the materials to form a continuous whole flow to be transported.

Special component

1. Scraper chain: alloy steel wear resistance forged links with carburizing heat treatment.

2. Head section: The head wheel is made of wheel hubs and head gear plate,head gear plate is made of alloy steel with quench heat treatment and has strong wear resistance.

3. Middle section: The rectangular closed case with upper and lower wear rail guides inside, the material is 65Mn or 60Si2Mn with heat treatment;the plate thickness of bottom and side plate is over 10mm, it can be customized.

4. Tail section: It has tension devices both sides to adjust the length of chains, to avoid the accident due to chain elongation.

Product Parameters

|

Model

(PE) |

Inlet size (mm)

|

Max feeding size (mm)

|

Capacity (t/h)

|

Motor (kw)

|

Weight

(t) |

Dimension

(L*W*H mm) |

|

PE-150*250

|

150*250

|

125

|

1-5

|

5.5

|

0.8

|

950*1100*1100

|

|

PE-200*300

|

200*300

|

180

|

2-10

|

7.5

|

1.2

|

1400*900*1200

|

|

PE-250*350

|

250*350

|

190

|

4-15

|

11

|

1.5

|

1400*930*1260

|

|

PE-250*400

|

250*400

|

210

|

5-22

|

15

|

2.8

|

1450*1350*1500

|

|

PE-400*600

|

400*600

|

350

|

18-60

|

30

|

7

|

1700*1800*1650

|

|

PE-500*750

|

500*750

|

425

|

43-102

|

55

|

10.6

|

2270*2370*2145

|

|

PE-600*900

|

600*900

|

500

|

51-180

|

75

|

16.5

|

3000*2500*2600

|

|

PE-750*1060

|

750*1060

|

630

|

80-195

|

110

|

29

|

2526*2410*2780

|

|

PE-900*1200

|

900*1200

|

780

|

140-270

|

132

|

52

|

2960*2760*3530

|

|

PE-1000*1200

|

1000*1200

|

850

|

190-310

|

132

|

55

|

3889*2826*3025

|

|

PE-1200*1500

|

1200*1500

|

1020

|

260-510

|

180

|

100.9

|

4930*3548*3702

|

|

PEX-150*750

|

150*750

|

120

|

8.5-28

|

18.5

|

3.8

|

1300*1750*1200

|

|

PEX-200*750

|

250*750

|

210

|

15-35

|

22

|

5.5

|

1400*1750*1400

|

|

PEX-250*1000

|

250*1000

|

210

|

20-65

|

37

|

7

|

1400*1980*1440

|

|

PEX-250*1200

|

250*1200

|

210

|

20-75

|

45

|

8.5

|

1400*2180*1440

|

|

PEX-300*1300

|

300*1300

|

250

|

30-105

|

70

|

11

|

1560*2350*1600

|

Company Certifications

Factory Show

Contact:

Mobile/ Wechat:+86-18660767011

Whatsapp:+86-15066371715

Hot Searches