- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

CHANDOR

-

Model Number:

-

1600

-

Type:

-

Two components Adhesive

-

Brand:

-

CHANDOR or Customized

-

Material:

-

A:Epoxy Resin+B:curing Hardener

-

Appearance of Part A B:

-

Transparent viscous liquid

-

Appearance after curing:

-

Transparent solid

-

Application:

-

Good adhesion for various substrates

-

Function:

-

Bonding /Sealing /Repairing /Filling

-

Certificate:

-

SGS/ROHS / REACH/ISO9001-2000

-

MOQ:

-

1200 kgs

-

Shelf life:

-

1 year

-

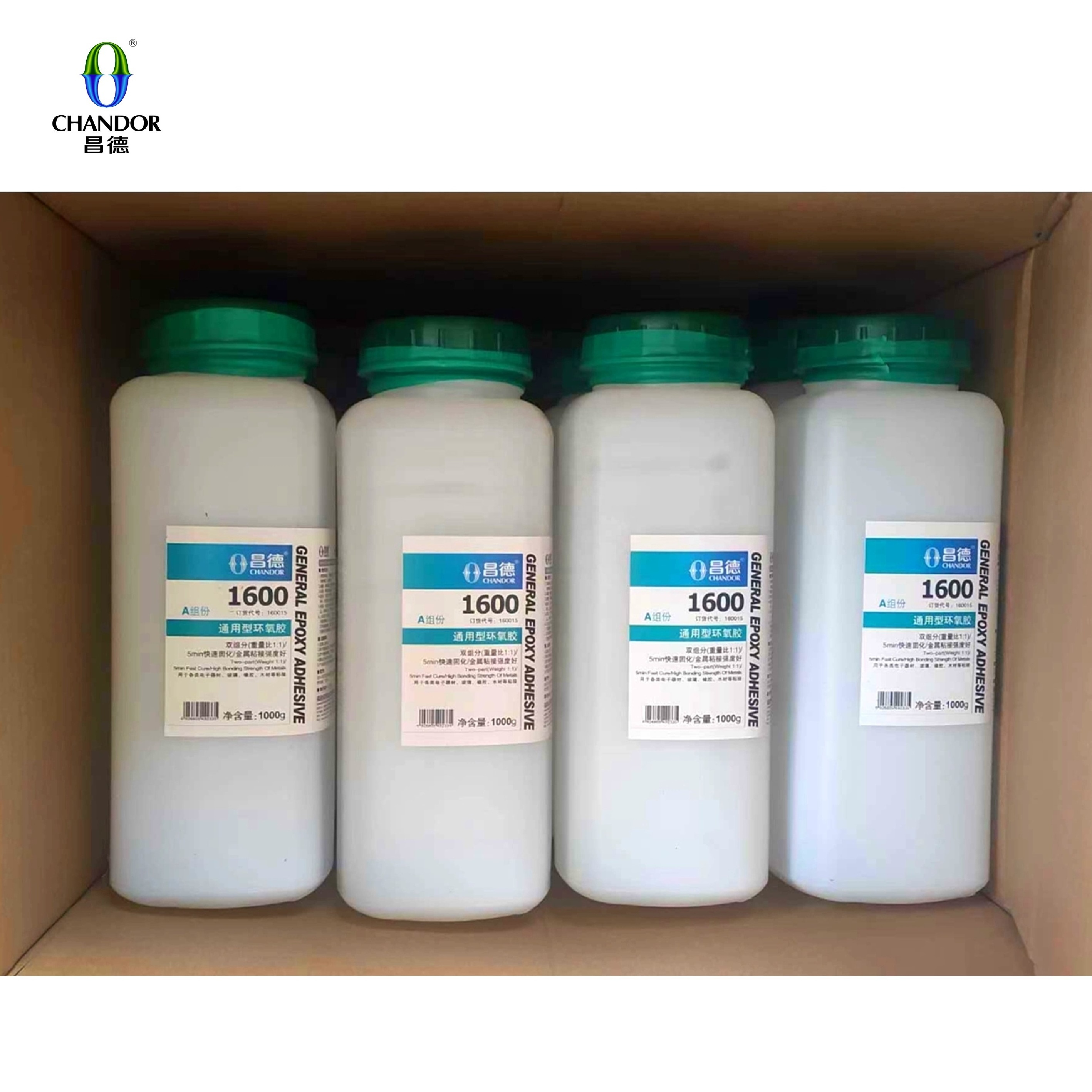

Package:

-

2kgs/set ,24kgs/carton

Quick Details

-

CAS No.:

-

N/A

-

Other Names:

-

Epoxy adhesive /Stone glue

-

MF:

-

N/A

-

EINECS No.:

-

N/A

-

Place of Origin:

-

Fujian, China

-

Brand Name:

-

CHANDOR

-

Model Number:

-

1600

-

Type:

-

Two components Adhesive

-

Brand:

-

CHANDOR or Customized

-

Material:

-

A:Epoxy Resin+B:curing Hardener

-

Appearance of Part A B:

-

Transparent viscous liquid

-

Appearance after curing:

-

Transparent solid

-

Application:

-

Good adhesion for various substrates

-

Function:

-

Bonding /Sealing /Repairing /Filling

-

Certificate:

-

SGS/ROHS / REACH/ISO9001-2000

-

MOQ:

-

1200 kgs

-

Shelf life:

-

1 year

-

Package:

-

2kgs/set ,24kgs/carton

Product Description

Two

part

s

transparent clear

m

odified epoxy adhesive,

5 minutes fast cure.

Solvent

free,

Good adhesion to various substrates.

Excellent

impact resistance and

excellent adhesive strength.

Low Temperature

curing to -40

℃ and

heat resistance to 100

℃.

A

cid and alkali

resistance.

Humidity proof

and waterproof

, oil -proof,

dust proof

and

chemical erosion proof.

Excellent for a myriad of purposes

including general purpose

adhesion and sealing, and for electronic device bonding, filling, repair, casting and impregnation.

|

5 Min Transparent Clear Epoxy 1600

|

PU - 8100

|

|

|

Waterproof Non-toxic Eco-friendly

Epoxy Adhesive For Muti- purposes

|

|

|

|

Features

|

Fast curing, high strength, waterproof, acid and alkali resistance, oil resistance, solvent resistance, excellent performance.

Non-flammable, non-shrinkable, can be filled, can be ground, can be drilled.

It is the best choice for bonding glass, decorative panels and bonding displays.

|

|

|

Typical use

|

1)Automotive Manufacturing

2)Consumer Electronics Industry

|

|

|

Packing

|

2kg/set , 24kgs/carton

|

|

|

Shelf Life

|

1 year

|

|

|

MOQ

|

1200 pcs

|

|

Instructions

1. Please

slightly polish, clean and completely dry the bonding parts before applying the adhesive.

2. Pre-heat

the adhesive to enhance the permeability of the adhesive, accelerate the curing process,and enhance the mechanical performance of cured epoxy resin.

3.Accurately measure part A and B by weight ratio, and sufficiently mix them well until the color of mixture is even without stripes,then equally coat the adhesive on the bonding parts with the scraper.

4.Impose some pressure after adhering the bonding parts, or adopt static curing. It's available for the next processing procedure 24 hours after curing at room temperature. When temperature is low in winter warm up the bonding compound to 50℃ ~ 60℃ to cure,and it's available for the next processing procedure after 3 ~ 4 hours.

5.Different colors can be prepared according to stone color , and the proper toner amount is no more than 0.3 ~ 3 ‰ of adhesive amount.

3.Accurately measure part A and B by weight ratio, and sufficiently mix them well until the color of mixture is even without stripes,then equally coat the adhesive on the bonding parts with the scraper.

4.Impose some pressure after adhering the bonding parts, or adopt static curing. It's available for the next processing procedure 24 hours after curing at room temperature. When temperature is low in winter warm up the bonding compound to 50℃ ~ 60℃ to cure,and it's available for the next processing procedure after 3 ~ 4 hours.

5.Different colors can be prepared according to stone color , and the proper toner amount is no more than 0.3 ~ 3 ‰ of adhesive amount.

Product Paramenters

Below relevant product data and descriptions provided in this document are based on a specific environment Under test or our current knowledge and experience. The actual application of products is affected by artificial or natural factors such as substrates, processes, equipment, environment, storage, transportation, user experience, etc.

|

Technical Indexes

|

|

|

||

|

Characteristics before curing

|

|

|

||

|

Items

|

Typical Parameters

|

Range

|

||

|

Component A

|

|

|

||

|

Appearance

|

Colorless transparent liquid

|

|

||

|

Base chemical composition

|

Epoxy resin

|

|

||

|

Viscosity (cps)(GB/T2794)

|

13,000

|

10,000 ~15,000

|

||

|

Component B

|

|

|

||

|

Appearance

|

Colorless transparent liquid

|

|

||

|

Base chemical composition

|

Amine curing agent

|

|

||

|

Viscosity (cps)(GB/T2794)

|

15,000

|

10,000 ~40,000

|

||

|

Mixing characteristics

|

|

|

||

|

Mixing weight ratio

|

A : B = 1 : 1

|

|

||

|

Applicable period (min)(6g @ 25℃)

|

2

|

1 ~ 2

|

||

|

Characteristics after curing

|

|

|

||

|

Appearance

|

Colorless transparent solid

|

|

||

|

Curing time (min)(1-3mm thin layer peeling time)

|

5

|

4 ~ 6

|

||

|

Shear strength (MPa)(GB/T7124)

|

14.21

|

≥7

|

||

|

Hardness (D)(GB/T2411)

|

75

|

≥70

|

||

|

Working temperature (℃)

|

- 40 ~ 100

|

|

||

Precautions

1.Please keep working condition ventilated and dry when processing.2.Wear protective mask and gloves.

3.Clean and dry the material surface before processing to make sure good bonding effort.

4.Please prepare A, B parts equally according to required ratio.

5.Do not prepare too much adhesive one time, the higher temperature cause faster curing which will shorter the usable time.

6.Do not move the adhesive-coated stones in case the overflow adhesive pollutes the stone surface.

7.Please stop using if the adhesive is too viscous or becomes gel.

8.Do not put the remaining mixed adhesive back to the packing barrel in case that it 'll affect the storage stability.

9.Do not misuse or mix the tools for A, B parts.

10. Pre-heat the stone before coating the adhesive or apply thermal curing after coating the adhesive to improve producing efficiency. The adhesive layer is not able to dissolved once cured, unless might or high temperature (≧ 200℃) is employed .

3.Clean and dry the material surface before processing to make sure good bonding effort.

4.Please prepare A, B parts equally according to required ratio.

5.Do not prepare too much adhesive one time, the higher temperature cause faster curing which will shorter the usable time.

6.Do not move the adhesive-coated stones in case the overflow adhesive pollutes the stone surface.

7.Please stop using if the adhesive is too viscous or becomes gel.

8.Do not put the remaining mixed adhesive back to the packing barrel in case that it 'll affect the storage stability.

9.Do not misuse or mix the tools for A, B parts.

10. Pre-heat the stone before coating the adhesive or apply thermal curing after coating the adhesive to improve producing efficiency. The adhesive layer is not able to dissolved once cured, unless might or high temperature (≧ 200℃) is employed .

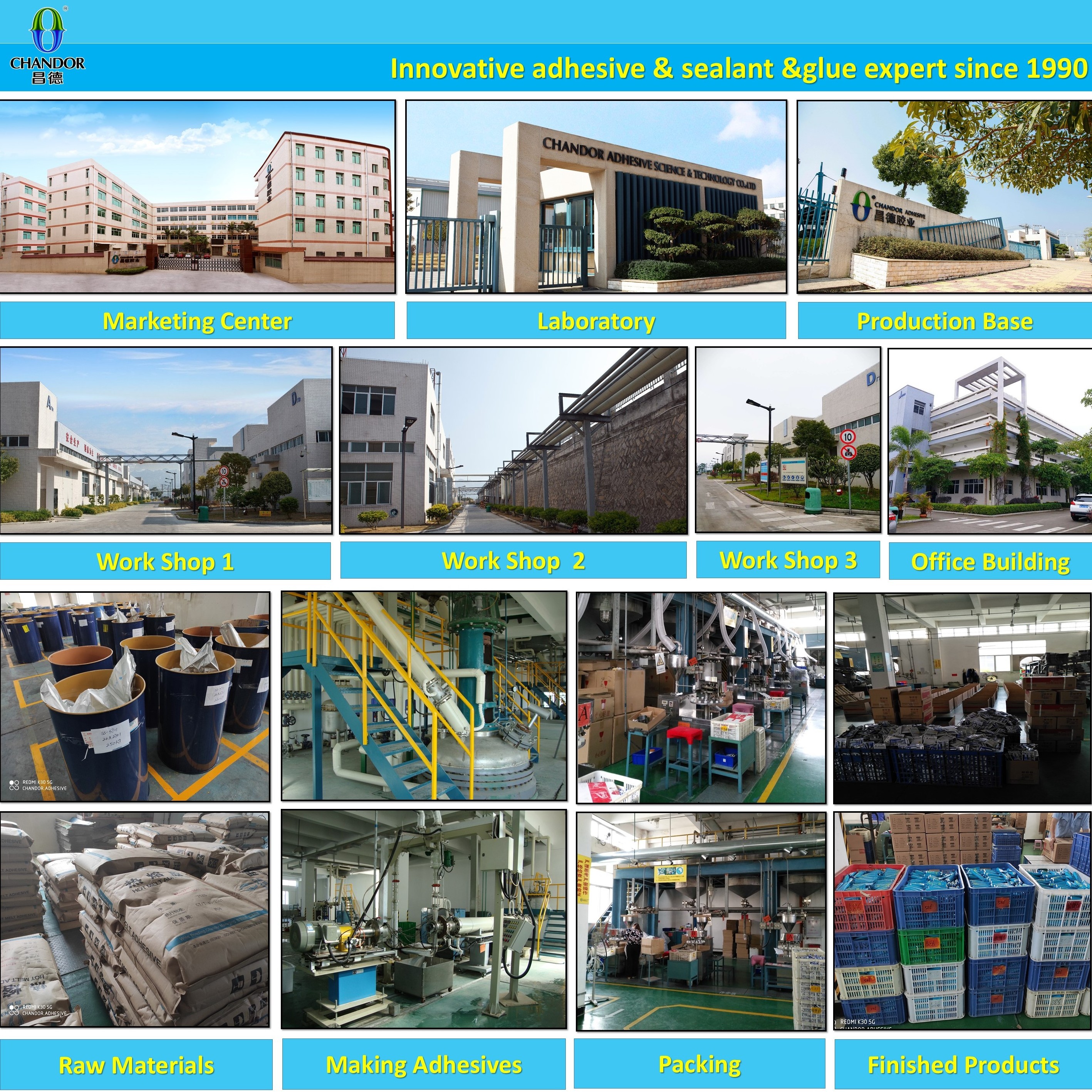

Company Introduction

Chandor is biggest ahesive manufacturer in China Fujian and established in 1990. We have 40,000 square meters production base, more than 50 professional technicians working together with 300 skilled workers to provide you high-tech products and professional technical services.

Our Services & Strength

1.Chandor

has established stable cooperation with global upstream suppliers of chemical raw materials to ensure the purity and stable performance of raw materials.

2.

Chandor has 30 years of technical accumulation and experience in the field of industrial adhesives.

3.Chandor R & D and application engineers work closely together during the product development and design phase, on-site application process and material matching test phase to ensure that all technical issues are properly resolved from the beginning.

Certifications

Chandor has passed ISO9001: 2000 quality management system certification; ISO14001: 2004 environmental management system certification; OHSAS18001: 1999 occupational health and safety management system certification

.

Related Products

FAQ

Q: Are you manufacturer or trading company?

A: Chandor is the biggest adhesive manufacturer in China Fujian and established in 1990. We have 40,000 square meters production base, more than 50 professional technicians working together with 300 skilled workers to provide you high-tech products and best technical services.

Q: How long can I get a quote?

A: The quotation can be provided not late than 24 hours on condition that we know all detailed requirements from your side.

Q: What is your payment terms?

A: T/T 30% in advance and 70% balance paid before delivery . For small order,100% deposit before production.

Q: What is the minimum order quantity?

A: 1000 to 1200 pcs for each sort of adhesives and sealants.

Q: What's the delivery time?

A: The Delivery time normally is 2-3 days after confirmation for samples, and for purchase orders, the delivery time is 15-45 days depend on variety of adhesives or as per customer's various request.

Q: How can you guarantee the quality?

A: Firstly ,Chandor has stable cooperation with global upstream suppliers of chemical raw materials to ensure the purity and stable performance of raw materials;The Secondly ,core raw materials of Chandor Adhesive are from international famous brand suppliers, such as Dupont, BASF, DOW, Sinopec,etc.

Secondly, Chandor has long-term project cooperation and technical exchanges with experts from Germany, Japan, and Taiwan and rigorous quality control for the mass production by our professional QC people.

Q: Can I get a sample?

A: Small doze of free samples is available and delivery cost is to be paid by clients.

Q: Can you provide OEM service?

A: Sure ,we can provide OEM service, Logo and design need to be provided so as to make customized brand-name,etc. Welcome to build a long relationship with us.

Hot Searches