- Product Details

- {{item.text}}

Quick Details

-

Power:

-

10Kw-70Kw

-

Weight:

-

2 KG

-

Dimension(L*W*H):

-

customized

-

Product name:

-

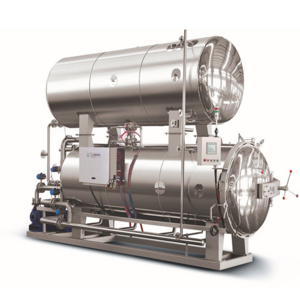

glass bottle beverage sterilization machine

-

Application:

-

beverage

-

Material:

-

Stainless Steel SUS304

-

Control system:

-

Fully Automatic

-

Sterilizing way:

-

Water spray

-

Heating way:

-

Steam

-

Design Temperature:

-

147 Degree Centigrade

-

Max pressure:

-

0.35 Mpa

-

Advantage:

-

High Efficiency, low consumption

-

cetificate:

-

CE

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Sterifood

-

Voltage:

-

Custimized

-

Power:

-

10Kw-70Kw

-

Weight:

-

2 KG

-

Dimension(L*W*H):

-

customized

-

Product name:

-

glass bottle beverage sterilization machine

-

Application:

-

beverage

-

Material:

-

Stainless Steel SUS304

-

Control system:

-

Fully Automatic

-

Sterilizing way:

-

Water spray

-

Heating way:

-

Steam

-

Design Temperature:

-

147 Degree Centigrade

-

Max pressure:

-

0.35 Mpa

-

Advantage:

-

High Efficiency, low consumption

-

cetificate:

-

CE

Products Description

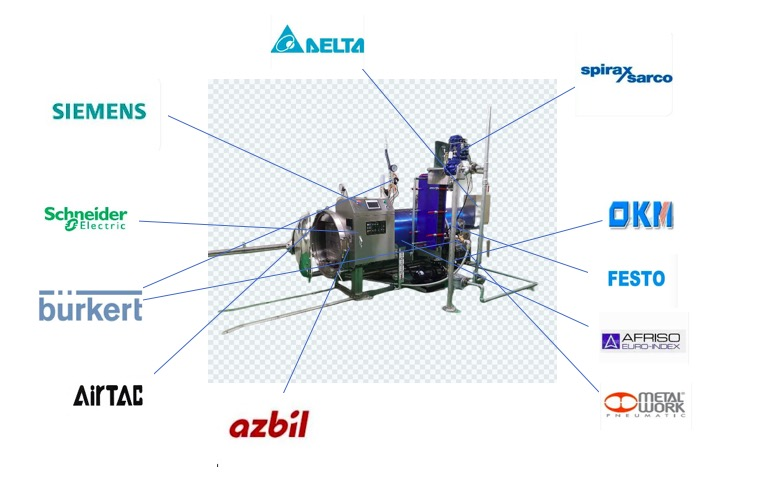

World well known Parts Assembled

This retort is perfectly suited for food sterilization. The Sterifood static is fitted with a powerful pump, for shorter and more homogeneous cycles. All the products inside the autoclave get the same thermal treatment, regardless of their position. The reduced cycle time also ensures better results.

Water sprays running over the entire shell length intensely mix the steam and water and create a homogeneous temperature distribution that results in a uniform process throughout the retort. Indirect, sterile cooling via a plate heat exchanger saves water and eliminates the need for water treatment chemicals.

Water sprays running over the entire shell length intensely mix the steam and water and create a homogeneous temperature distribution that results in a uniform process throughout the retort. Indirect, sterile cooling via a plate heat exchanger saves water and eliminates the need for water treatment chemicals.

Features & Benefits

* Reduced process time

* Efficient heat distribution

* High quality design and construction

* Micro cooling

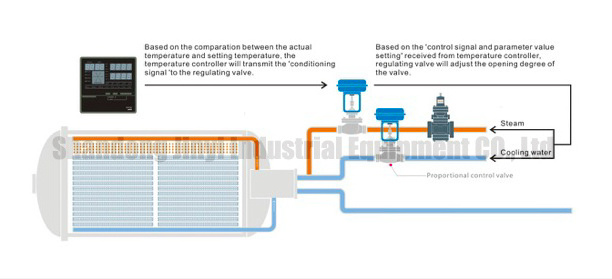

* Precise temperature and pressure control

* Precise, reproducible execution of pre-programmed recipes

* Automatic PID temperature controller, temperature error within±0.3℃

* Temperature contrast in the retort(heat distribution)±0.3℃

Applications

Retorts are at the heart of many shelf-stable food processing lines such as:

* Ready-meals

* Baby food, pet food, soups, sauces

* Mushrooms, vegetables, beans, and more

* Milk (plain, chocolate, milkshakes, cream, etc.)

* Fruits juices, non-carbonated beverages, tea, coffee, etc.

I nside pic for reference :

Diagram Map

(A low amount of water is kept in the bottom of the retort chamber. During all the process cycle (sterilization & cooling) this amount of water is recirculated by a high flow rate pump and uniformly distributed with one inlet per basket. Heating and cooling of this water is made through a plate heat exchanger.)

Design Drawing

Two Option (HE back or side location which can save the space )

Details Images

SPIRAXSARCO proportional valve

Special leg cover design for expand when heated

Manual and auto dual system

Multiple safety interlock designs

Model And Capacity Reference

Hot Searches