- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

channel letter bending machine

-

Keyword:

-

letter bending machine

-

Name:

-

channel letter bending machine

-

Machine Type:

-

cnc channel letter bending machine

-

Applier material:

-

S.S; Iron sheet; Flat aluminum

-

Material thickness:

-

iron, S.S, aluminum:0.3-1.2mm

-

Material width:

-

10mm-130mm

-

Precision:

-

0.05mm

-

Cutting/Bending way:

-

Double side cutting and bending

-

Input file format:

-

dxf , ai

Quick Details

-

Place of Origin:

-

Guangdong, China

-

Year:

-

New

-

Weight (KG):

-

480

-

Product name:

-

channel letter bending machine

-

Keyword:

-

letter bending machine

-

Name:

-

channel letter bending machine

-

Machine Type:

-

cnc channel letter bending machine

-

Applier material:

-

S.S; Iron sheet; Flat aluminum

-

Material thickness:

-

iron, S.S, aluminum:0.3-1.2mm

-

Material width:

-

10mm-130mm

-

Precision:

-

0.05mm

-

Cutting/Bending way:

-

Double side cutting and bending

-

Input file format:

-

dxf , ai

Note: This quotation is a deposit, please contact the salesperson for details of the customized machine.

Product Description

Specification

|

Applier material

|

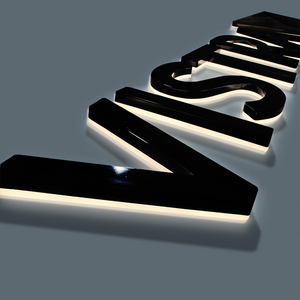

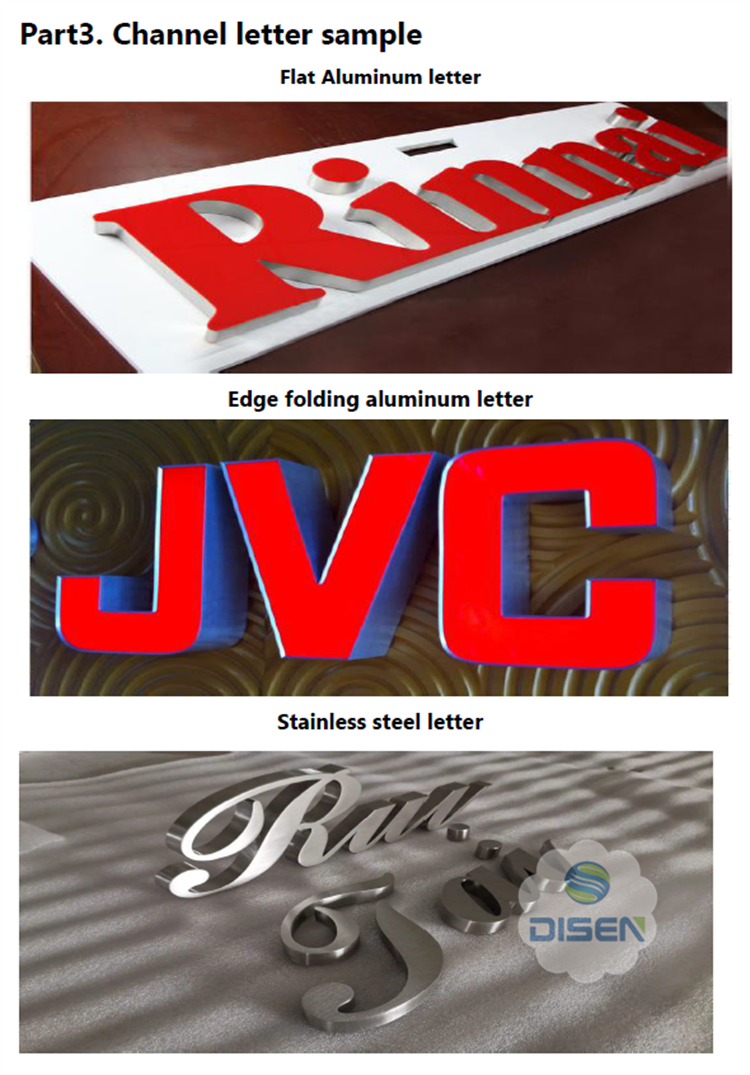

S.S; Iron sheet; Flat aluminum

|

|

Material thickness

|

iron, S.S, aluminum:0.3-1.2mm

|

|

Material width

|

10mm-130mm

|

|

Power

|

2000W

|

|

Voltage

|

AC220V,50HZ

|

|

Size

|

1700mm*800mm*1650mm

|

|

Weight

|

480kg

|

|

Motor

|

Two servo motors (one for cutting and one for bending) and tepper motor with nice stability

|

|

Precision

|

0.05mm

|

|

Cutting/Bending way

|

Double side cutting and bending

|

|

Input file format

|

dxf , ai

|

|

Feeding speed

|

60mm/s (it takes only 48 seconds to finish a letter “S” of 30cm)

|

|

Slotting angle

|

45°-135°

|

|

The min bending arc diameter

|

15mm

|

|

Roller

|

Rubber roller for feeding; copper roller for bending, which can protect the surface of material and make finished letter more

beautiful |

|

Working Principle

|

Auto-feeding; auto-slotting; auto-bending;auto-depth adjusting

|

Product advantages

1. The progressive clamping and feeding of double manipulators make the feeding more stable and precise.

2. The slotting drive and bending system are driven by high-power servo motors, and the bending is equipped with a 1:16 reducer, which greatly increases the bending torque.

3. The stainless steel and galvanized sheet adopt the cutting mode of imported planer granules, and the aluminum profile and flat aluminum material use a specially customized 90-degree milling cutter head.

4. After the cutting blade is worn out, it can be quickly replaced, which greatly improves the work efficiency.

5. Automatically detect the cutting depth, which can realize the function of multiple feeding and prolong the service life of the blade.

6. The original pneumatic clamping feeding structure can adjust the clamping force according to the thickness of the profile to reduce material indentation without adjusting parameters.

7. The fuselage adopts humanized design, which is convenient to operate.

8. The control system adopts Chengdu Lechuang dual-card system, which has strong stability and anti-interference ability. The integrated circuit board independently developed and designed by the power panel according to the equipment performance greatly reduces the probability of equipment failure caused by regional voltage instability.

9. Low energy consumption, the total power is 5000w, and the actual power used does not exceed 2000w.

10. Compatible with more software's DXF/AI file format, support. ARTCAM, CASMATE, TYPE3, CORELDRAW, ILLUSTRATOR, FLEXISIGN, ENROUTER, etc., match with engraving machine, plasma cutting machine, laser cutting machine.

11. Automatically identify the inner and outer frames of the graphics, automatically calculate the length, interrupt at any point, and change the overlapping form.

12. Dimensions: length 1760mm*width 700mm*height 1500mm

13. Processing materials: stainless steel, iron sheet, aluminum profiles. Processing width: 30mm-128mm.

Processing thickness: 0.4mm-1.2mm.

14.Special specifications and requirements can be customized.

Hot Searches