- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V, 380v 50hz

-

Power:

-

200kw

-

Dimension(L*W*H):

-

35*8*6m

-

Weight:

-

20 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

capacity:

-

2500pcs/hr

-

water comsumption:

-

280kg/h

-

moulding system:

-

roller and reciprocating type

-

gas consumption:

-

32m3/h

-

Raw material:

-

Waste paper

-

Processing type:

-

Pulp moulding machine

Quick Details

-

Production Capacity:

-

2500pcs/hr

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Clima

-

Voltage:

-

380V, 380v 50hz

-

Power:

-

200kw

-

Dimension(L*W*H):

-

35*8*6m

-

Weight:

-

20 kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

capacity:

-

2500pcs/hr

-

water comsumption:

-

280kg/h

-

moulding system:

-

roller and reciprocating type

-

gas consumption:

-

32m3/h

-

Raw material:

-

Waste paper

-

Processing type:

-

Pulp moulding machine

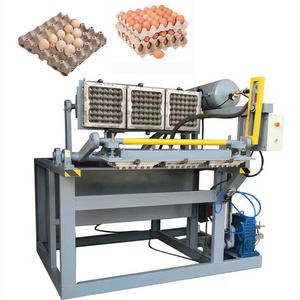

2000-3000pcs/hr ce approved 5000pcs/h paper pulp molding tray machine price

Egg carton paper pulp moulding machine uses waste paper as raw materials to produce different kinds of products according to your requirements, such as egg trays, egg cartons, egg boxes, apple trays, fruit trays, industrial trays, seeding trays etc. Our machine include pulp making system ,forming system and drying system.

Advantage of Recycling egg carton making machine:

1. Raw material: Any kind of waste paper like old newspaper,magazines,books,A4 paper etc, and easy to get

2. Automation: Fully-automatic control

3. Quality standard: CE

4. 100% environmentally production process.

5. Engineers available to service machinery overseas.

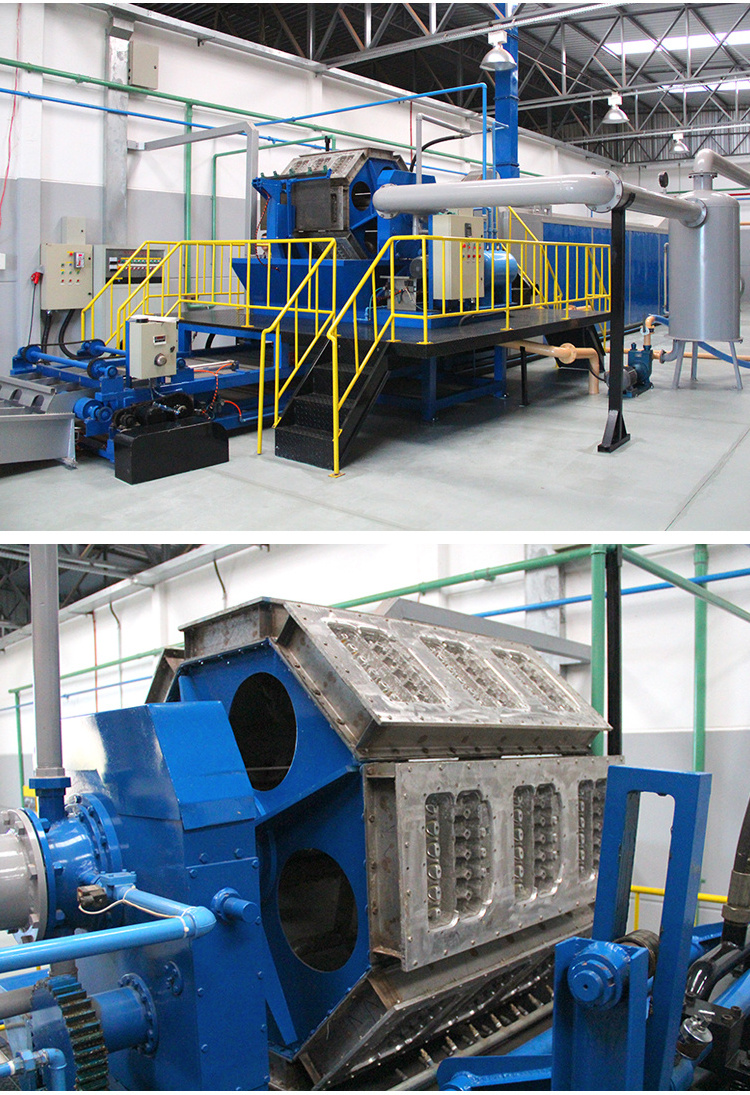

Pulp Making System:

Hydraulic, Pulp Pump, Pulp Screen Machine, Pulp Breaking Machine, Stirrer and so on.

Moulding System:

Rotary Type Molding Machine, Vacuum Pump, Air Compressor, Vacuum Tank, Water Pump and so on..

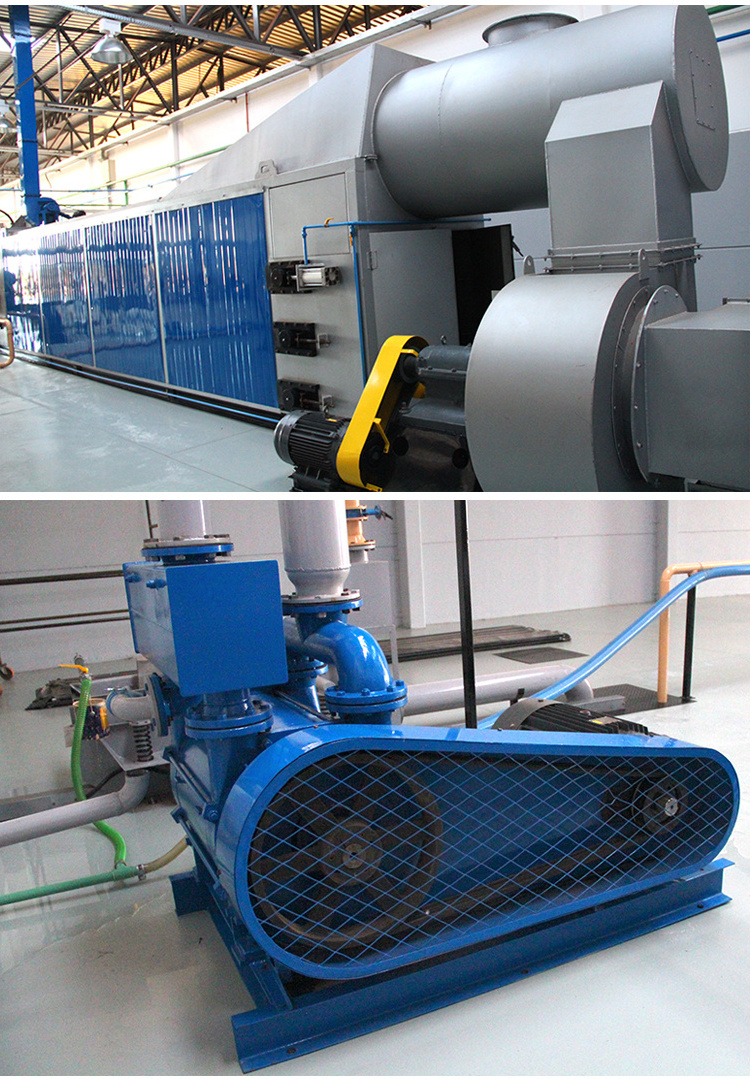

Drying System:

Bellows, Air Blower, Conveyer

Packaging Machine:

High quality of pulp molding machine for paper trays could design according to the customer’ requirement.

High speed egg carton machine production line flow chat

Egg tray production line parts details for your rerference.

Capacity:

720pcs/hr,1500pcs/hr,2000pcs/hr,3000pcs/hr,4000pcs/hr,5000pcs/hr,6 000pcs/hr, 8000pcs/hr,10000pcs/hr,12000pcs/hr

| Model Number | 10000 | 8000 | 6000 | 5000 | 4000 | 3000 | 2000 | 1500 | 720 |

| Floor space | 40m*15m*6m | 40m*15m*6m | 40m*10m*6m | 40m*10m*6m | 35m*8m*6m | 35m*8m*6m | 35m*8m*6m | 35m*8m*6m | 35m*8m*6m |

| Voltage | 380 V | 380 V | 380 V | 380 V | 380 V | 380 V | 380 V | 380 V | 380 V |

| Frequency | 50 Hz | 50 Hz | 50 Hz | 50 Hz | 50 Hz | 50 Hz | 50 Hz | 50 Hz | 50 Hz |

| Production capacity | 10000-12000pcs/h | 8000-10000pcs/h | 6000-7200pcs/h | 5000-6600pcs/h | 4000-5000pcs/h | 3000-4800pcs/h | 2000-3000pcs/h | 1500-2000pcs/h | 720-960pcs/h |

| Drying system | Six layers or eight layers | Six layers or eight layers | Six layers or eight layers | Six layers or eight layers |

Six layers or

Single layer |

Six layers or

Single layer |

Single layers | Single layers | Single layer |

| Water consumption | 1400kg/h | 1120kg/h | 840kg/h | 700kg/h | 560kg/h | 560kg/h | 280kg/h | 210kg/h | 100kg/h |

| Gas consumption | 160m3/h | 130m3/h | 97m3/h | 80m3/h | 65m3/h | 65m3/h | 32m3/h | 24m3/h | 12m3/h |

| Raw material | 700Kg/h | 560Kg/h | 420Kg/h | 350Kg/h | 280Kg/h | 210Kg/h | 140Kg/h | 105Kg/h | 50Kg/h Heating source |