- Product Details

- {{item.text}}

Quick Details

-

Keyword:

-

Stranding Dies

-

Hole size:

-

Hole 0.3-up to 25mm

-

Shaping Mode:

-

Extrusion Mould

-

Surface Finishing:

-

Polishing Treat

-

Die Case:

-

Stainless Steel or customized

-

Mould material:

-

Tungsten Carbide

-

Surface treatment:

-

Polishing

-

Application:

-

Household Product Mold

Quick Details

-

Place of Origin:

-

China

-

product name:

-

Dies for cable stranding and compacting | WIRE

-

Material:

-

Stainless steel outer case+ Tungsten carbide

-

Keyword:

-

Stranding Dies

-

Hole size:

-

Hole 0.3-up to 25mm

-

Shaping Mode:

-

Extrusion Mould

-

Surface Finishing:

-

Polishing Treat

-

Die Case:

-

Stainless Steel or customized

-

Mould material:

-

Tungsten Carbide

-

Surface treatment:

-

Polishing

-

Application:

-

Household Product Mold

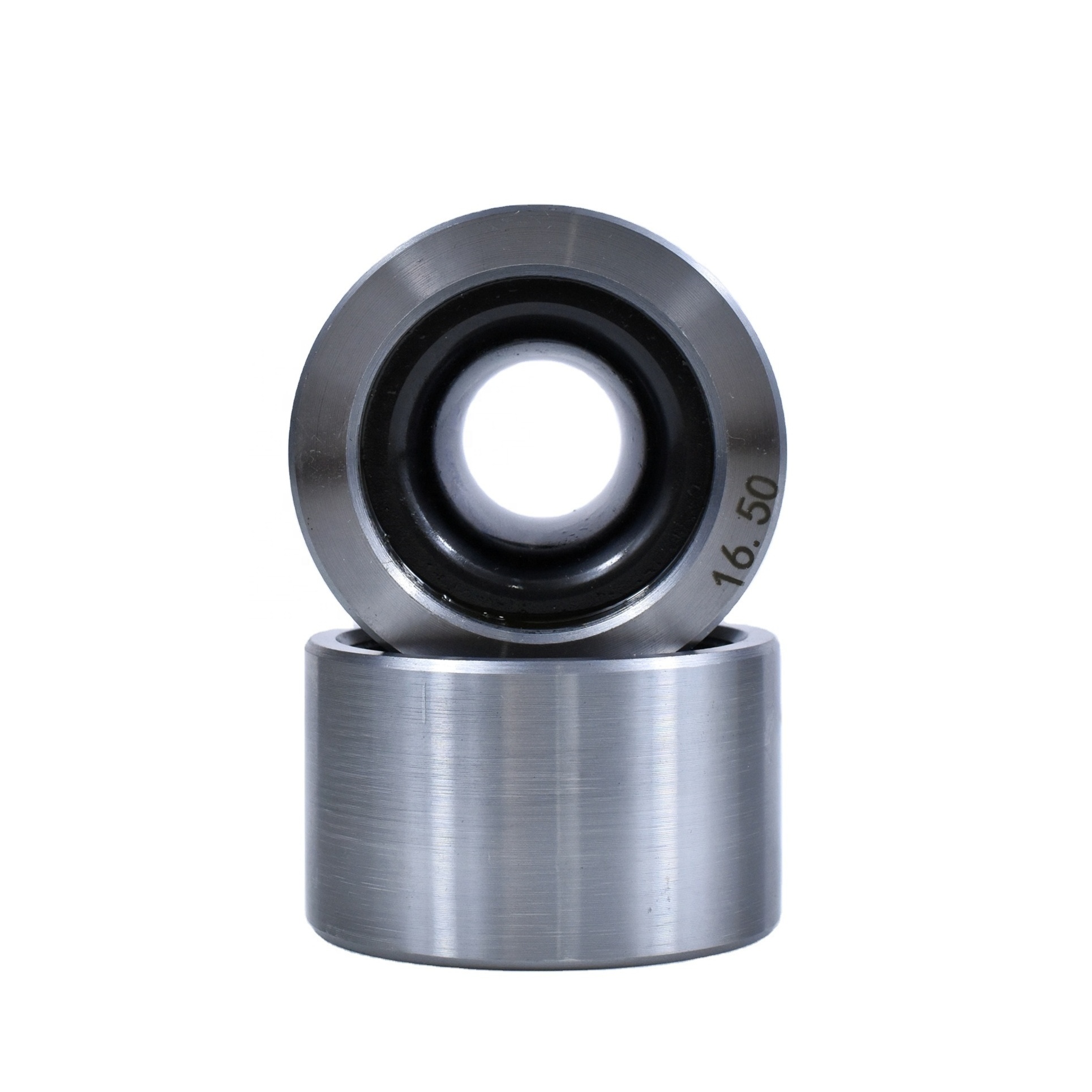

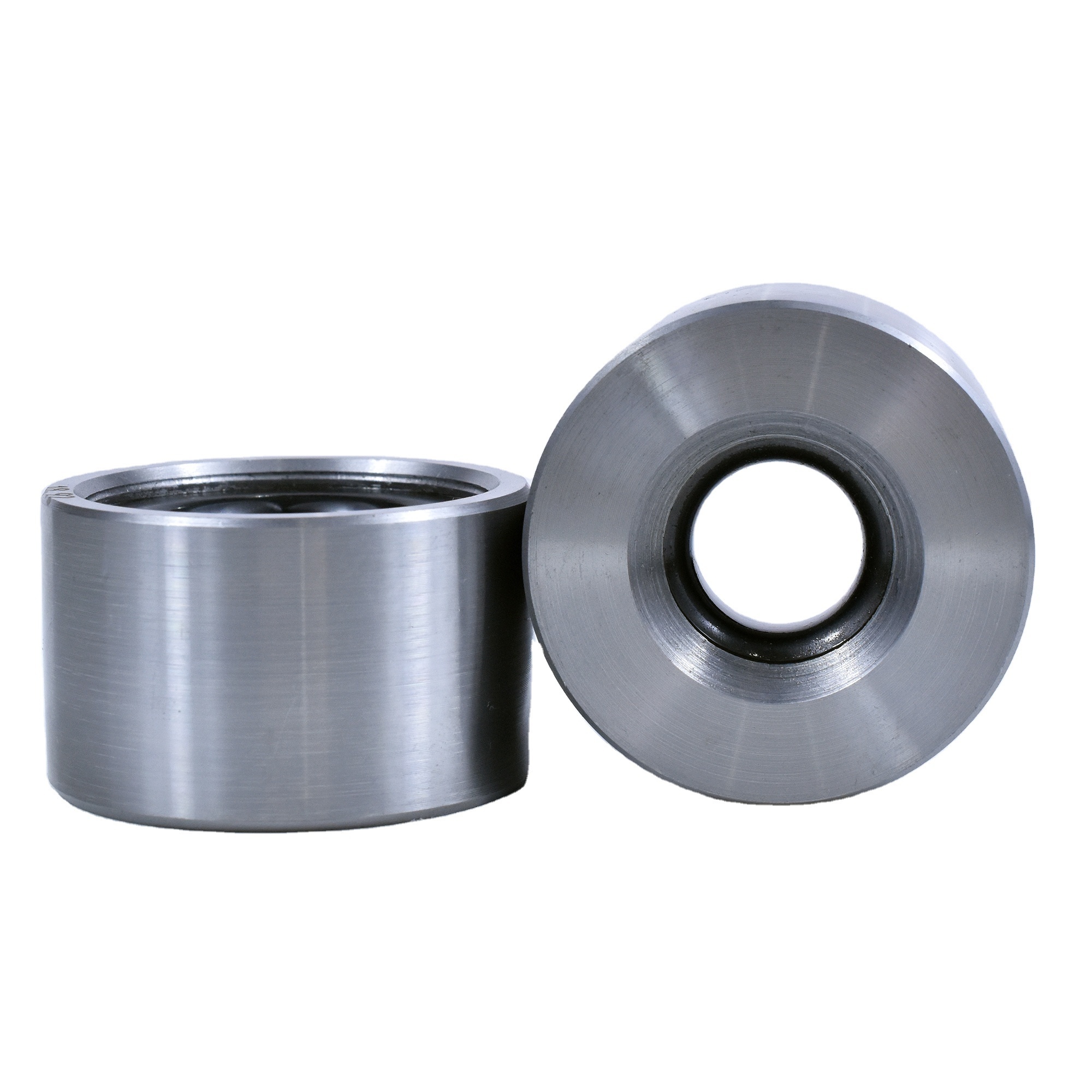

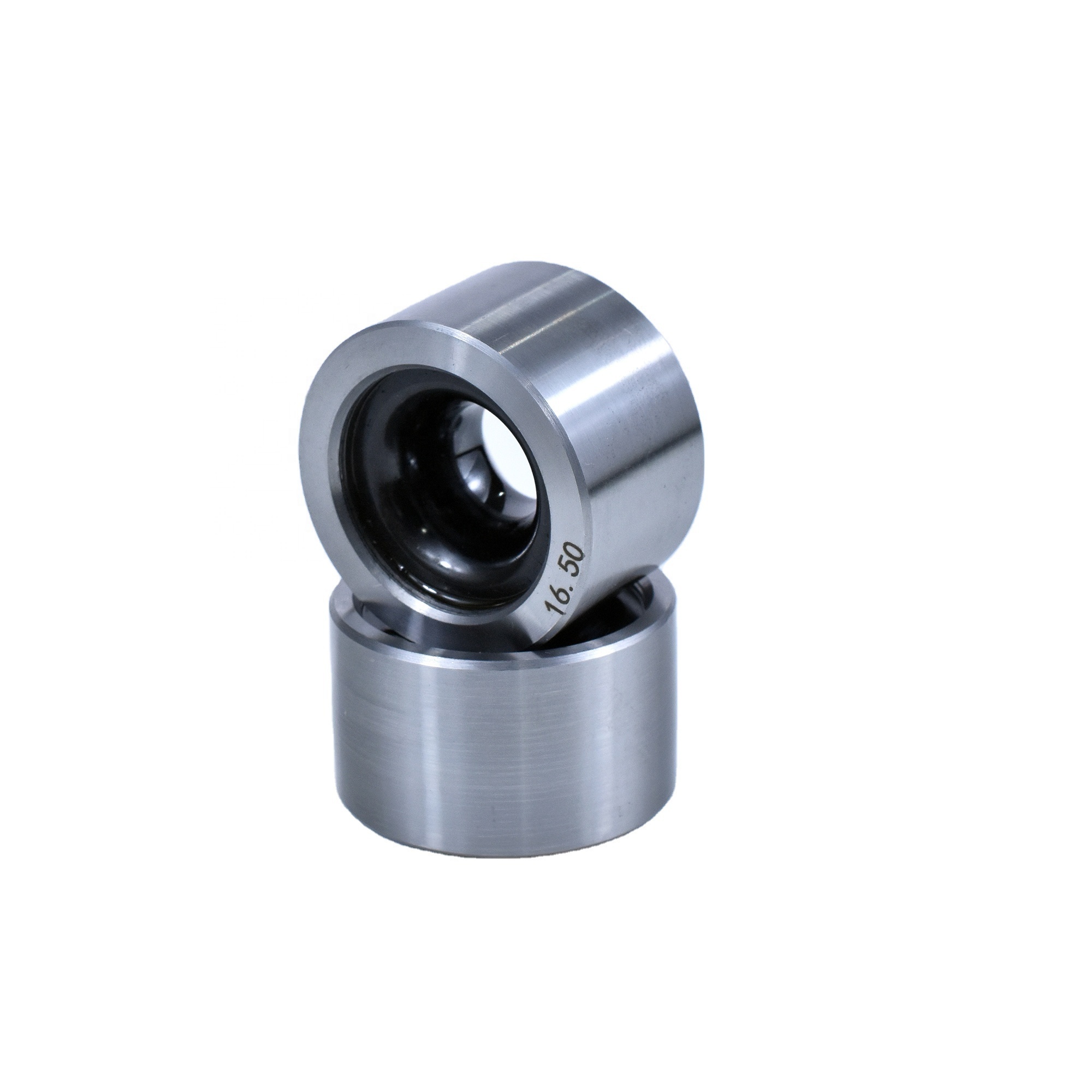

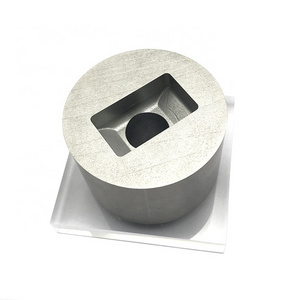

Dies for cable stranding and compacting | WIRE

The Description of Stranding Dies

The wire binding die and strand die are used to guide and / or organize metal wires through the wire binding machine and strand machine.The winding drum of double twist and single twist buncher is inside the machine, and the mold is fixed at the entrance of the machine to collect metal wires.We can provide stranded wire moulds of different materials: Tungsten carbide/PCD/Nano coated.

The advantages of Stranding Dies

- Tools suitable for stranding process.

- Wide range of application.

- Excellent performance and wire quality.

- Can be used for TC, PCD, and diamond coated molds (DC).

-

Lower die pull resistance for higher energy efficiency.

The spe cification of Stranding Dies

| Stranding dies sizes | |||||

| OD*Height | Hole Diameter Reduction | Reduction angle(°)-a | Reduction Zone Height(mm)- L1 | Bearing Length(mm)-L | β(°) |

| 20*17 | 4.9 | 28 | 5.5 | 1.5 | 65 |

| 22*18 | 7.2 | 28 | 5.5 | 2 | 65 |

| 25*18 | 8.2 | 28 | 5.5 | 2 | 65 |

| 30*18 | 11.5 | 28 | 7 | 2.5 | 70 |

| 30*18 | 13 | 28 | 7 | 2.5 | 70 |

| 35*22 | 15.9 | 28 | 7 | 2.5 | 70 |

| 38*22 | 18.3 | 28 | 7 | 3 | 70 |

The application of Stranding Dies

Applications include high, medium and low voltage cables and automotive wires. The wire diameter is accurately controlled and it is easy to obtain a bright wire surface. Aluminum, copper and other non-ferrous cable, dry-drawing of stainless steel, welding wire drawing and tube drawing.