As a daily chemical product, soap is popular in every family. Soap is made from natural materials, comparing with synthetic detergent, it is no harm to person and environment.

Soap is made from plant oil (or animal fat, or fatty acid) and caustic soda. The oil might be palm oil, coconut oil, palm kernel oil, tallow, cottenseed oil, etc. We offer the complete laundry soap line to customers who produce soaps starting from oil.

- Product Details

- {{item.text}}

Quick Details

-

Finally products:

-

Laundry Bar Soap

-

Machine Type:

-

Complete Soap Making Machine

-

Capacity:

-

1000~1500 kg/hr

-

Advantage:

-

Vacuum Dry System

-

Process:

-

Saponification

-

BRAND:

-

ZhongHui

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Zhonghui

-

Product name:

-

Bar Soap Making Machine

-

Finally products:

-

Laundry Bar Soap

-

Machine Type:

-

Complete Soap Making Machine

-

Capacity:

-

1000~1500 kg/hr

-

Advantage:

-

Vacuum Dry System

-

Process:

-

Saponification

-

BRAND:

-

ZhongHui

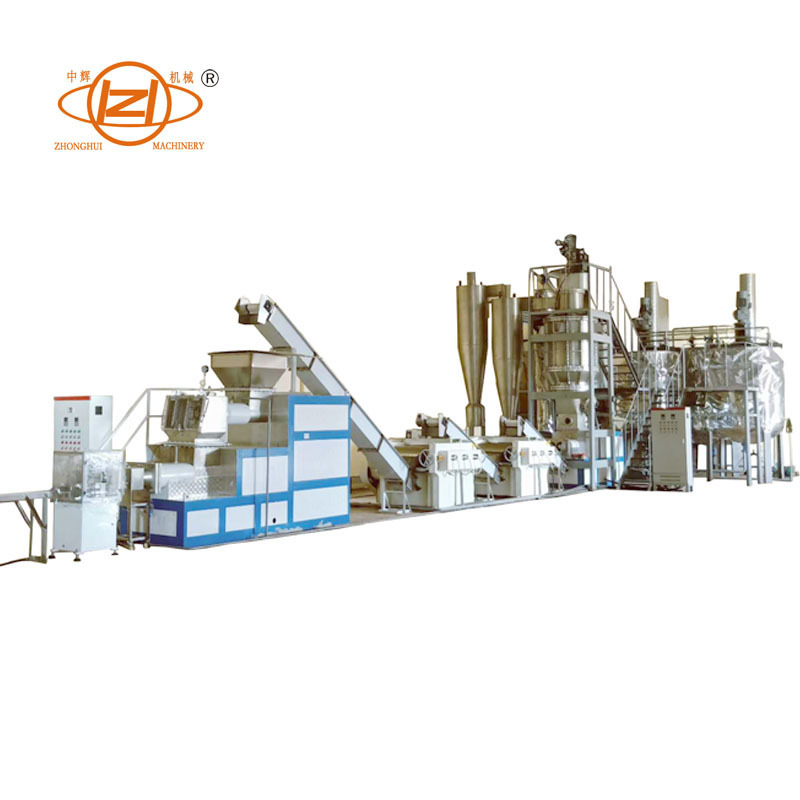

Complete soap production line

Product Description

This line is a soap complete line start from oil and caustic soda saponifying,vacuum drying to finishing line, its production process as following:

1. Melt & mix all kinds of oil.

2.Oils & caustic soda do saponifying

3.Vacuum drying & Extruding soap noodles

4.Finishing line: Mixonh-->>Grinding-->>Vacuum extrudeding-->>Stamping/Cutting to end bar soap.

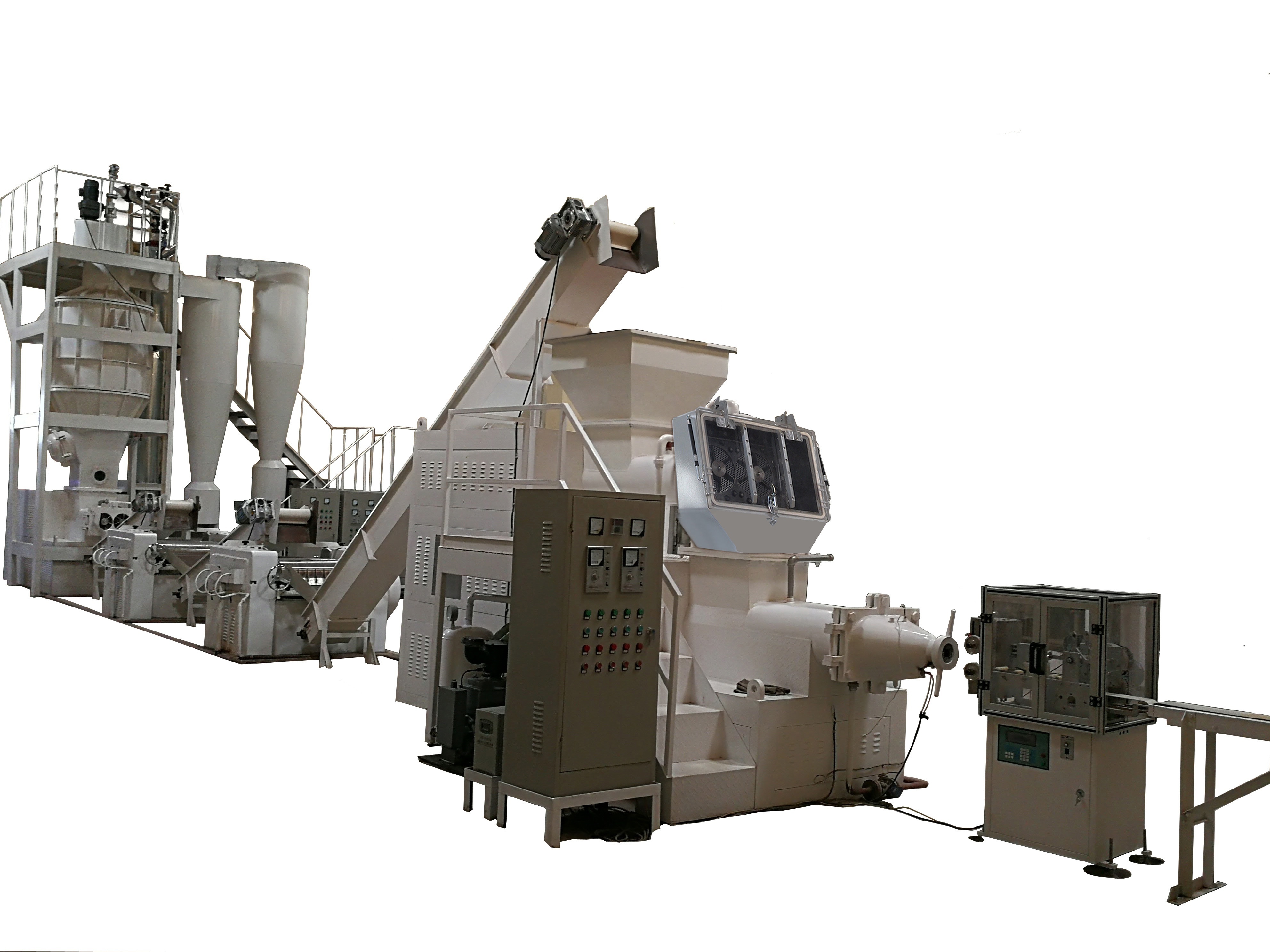

For the soap industry there have 2 steps as following:

Semi-product: soap noodles

Use all vegetanles oil or animal fat and caustic soda as material to produce semi-produce soap nooles

End bar soap: laundry soap

Use this semi-produce soap noodle to produce end bar soap. it can be laundry bar soap,toilet bar soap.

Details Images

Saponification & Neutralization Cauldron

Saponification between oil and caustic soda.

Neutrlization between factty acid and caustic soda.

Adopt undrained saponification,short reaction time,simple operation and less consumption of steam and water.

1.Material: stainless steel 304

2.Size: 1500,1800,2000

3.Structral features: built-in strring device.

4.Power: frequency conversion motor.

1 ton ~ 2 ton per hour 3 tans

2 ton ~4 tons per hour 4-5 tanks

|

Model

|

Capacity(kg/h)

|

Roll Diameter(mm)

|

Roll Speed(r/min)

|

Power(kw)

|

|

XSD-1000

|

1000-2000

|

1200

|

13

|

3.0

|

|

XSD-2000

|

2000-4000

|

1500

|

13

|

5.5

|

|

Model

|

Capacity(kg/h)

|

Screw Diamete(mm)

|

Power(kw)

|

Dimension(mm)

|

Weight(kg)

|

|

XSP-1000

|

1000-1500

|

Φ230

|

18.5

|

3200﹡1200﹡1500

|

2400

|

|

XSP-2000

|

1500-2500

|

Φ250

|

30

|

3400﹡1200﹡1500

|

2700

|

|

XSP-3000

|

2500-3000

|

Φ300

|

37

|

3600﹡1200﹡1600

|

3000

|

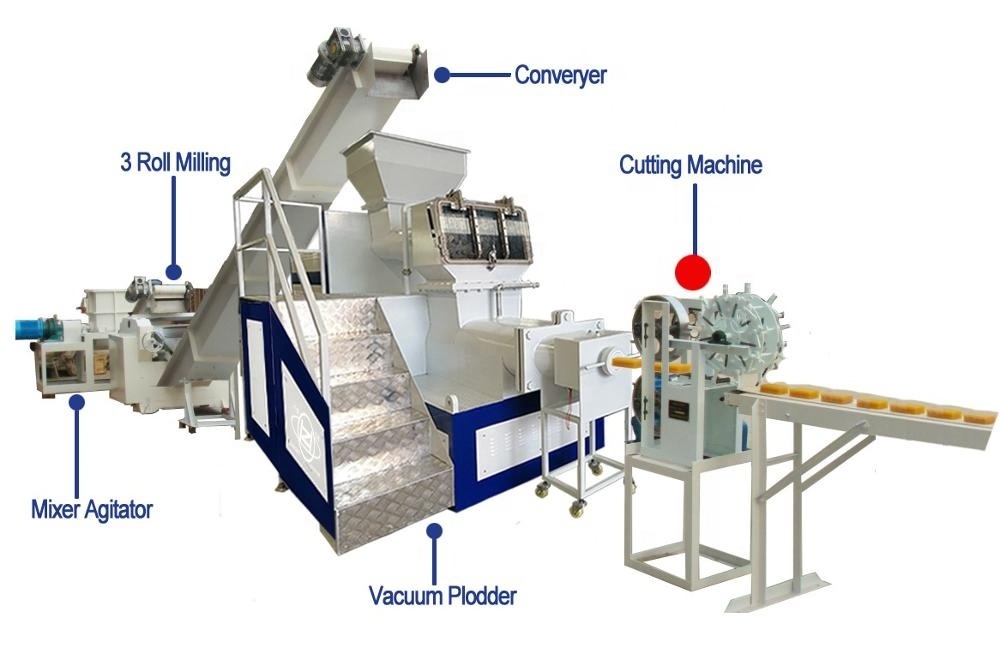

Mix soap noodle and other additives sufficiently.Adopt famous brand geared motor made in China

It's used to mix soap noodle and other additives sufficiently,make the soap structure tight and improve soap's density and quality.

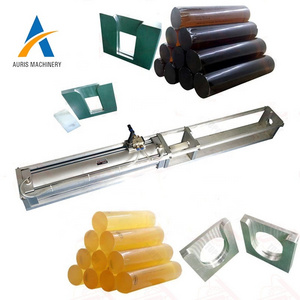

Soap electronic cutting machine is used to cut soaps into cakes and stamp pattern on the soap surface.

Our old design vacuum plodder

From 2006~ 2012 the first plodder, we are learning and developing all the time ,the product ungrade every year.

Our new design(update) vacuum plodder

Till 204 the new design was founed but there also ned some inner configuration are ungrade till 2019.

Installation Instructions

Why Choose Us

Our Advantages

Recommend Products

Hot Searches