Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

Screw Speed (rpm):

-

1200 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SEVENSTARS

-

Voltage:

-

220-460V

-

Dimension(L*W*H):

-

23x2x2m

-

Power (kW):

-

60

-

Weight:

-

7000 KG

-

Motor brand:

-

SIENEMS

-

Capacity/output:

-

80-300kg/hour

-

raw material:

-

PVC, Caco3, Stabilizer, CPE------

-

Caco3 ratio:

-

30%-200%

-

Further processing:

-

hot stamping, printing, laminating

-

Inverter brand:

-

SIENEMS

-

Auxiliary machines:

-

mixer, crusher, pulverizer

-

Machine color:

-

customized

-

Key words:

-

Pvc Sheet Production Line

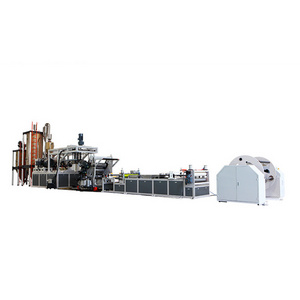

Quick Details

-

Screw Design:

-

Double-screw

-

Screw L/D Ratio:

-

33:1

-

Screw diameter (mm):

-

120 mm

-

Screw Speed (rpm):

-

1200 rpm

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

SEVENSTARS

-

Voltage:

-

220-460V

-

Dimension(L*W*H):

-

23x2x2m

-

Power (kW):

-

60

-

Weight:

-

7000 KG

-

Motor brand:

-

SIENEMS

-

Capacity/output:

-

80-300kg/hour

-

raw material:

-

PVC, Caco3, Stabilizer, CPE------

-

Caco3 ratio:

-

30%-200%

-

Further processing:

-

hot stamping, printing, laminating

-

Inverter brand:

-

SIENEMS

-

Auxiliary machines:

-

mixer, crusher, pulverizer

-

Machine color:

-

customized

-

Key words:

-

Pvc Sheet Production Line

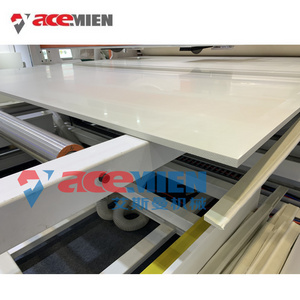

PVC ceiling panel board extrusion making machine

1.The equipment adapts to various formulations, the ratio of calcium can be increased up to 50%-250%, while the required accessories can be reduced by 30%

2.The ceiling the extruder products has an exquisite appearance and uniform plasticization

3. Laser tracking eliminates problems regarding the extrusion flow

rate, which helps achieve automation of the entire extrusion process

4 The PVC ceiling extrusion machine has auto-alarm functions in case of emergency, through the use of PID controller

Which is mainly used in the area of PVC ceiling, integrated ceiling, luggage

board, ceiling corner etc. the equipment consists of conical twin-screw extruder

vacuum shaping table, tractor, cutter and stacker, It has high-techlaser tracking

device exclusive, to ensure not only extrude PVC ceilings with high quality and

output also greatly reduce the cost of production, which get appreciations from

customers

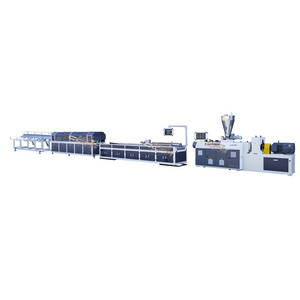

|

Model |

S JSZ48(50) |

S JSZ55 |

S JSZ65 |

|

M ain power(kw) |

1 5 |

2 2 |

3 7 |

|

P roduct width(mm) |

3 00 |

2 00-600 |

3 00-600 |

|

T otal Power(kw) |

3 4 |

4 7 |

6 6 |

|

O utput capacity(kg/h) |

1 10-160 |

1 20-190 |

1 50-210 |

|

L ength of line |

1 8.5 |

2 0 |

2 1.5 |

|

A ir compression(mpa/m3) |

0 .5 |

0 .6 |

0 .6 |