- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15-75KW

-

Dimension(L*W*H):

-

21.7m*18.6m*6.6m

-

Weight:

-

10000

-

Customization:

-

Yes

-

Processing material:

-

Polyethylene, PE

-

Scope of use:

-

Forming of large and medium-sized plastic hollow products

-

Forming method:

-

Rotary forming

-

Motor power:

-

55kW

-

Working volume:

-

20m ³

-

Working temperature:

-

280 degrees Celsius

-

Heating power:

-

30kw

-

Feed inlet diameter:

-

3000mm

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Jinxiu

-

Voltage:

-

220V/380V/440V, 380v

-

Power:

-

15-75KW

-

Dimension(L*W*H):

-

21.7m*18.6m*6.6m

-

Weight:

-

10000

-

Customization:

-

Yes

-

Processing material:

-

Polyethylene, PE

-

Scope of use:

-

Forming of large and medium-sized plastic hollow products

-

Forming method:

-

Rotary forming

-

Motor power:

-

55kW

-

Working volume:

-

20m ³

-

Working temperature:

-

280 degrees Celsius

-

Heating power:

-

30kw

-

Feed inlet diameter:

-

3000mm

Product Description

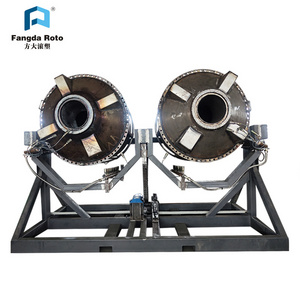

Shuttle type Rotational Molding machine

2A-3000 two arms Shuttle plastic molding rotational plastic molding machine

The rotational molding process offers several advantages. Manufacturing large, hollow parts such as our poly snouts is more easily done by rotational molding than any other method. Rotational moulds are considerably less expensive than other types of moulds. The products can be custom-designed to meet precise market requirements more economically than by conventional injection or blow molding.

Very little material is wasted using this process, and excess material can often be re-used, making it a very economically and environmentally viable manufacturing process. What material is wasted, through scrap or failed part testing, can be recycled.

The process also has fundamental design strengths, such as consistent wall thickness and strong outside corners that are essentially stress free.

rotational molding machine MATERIALS:

More than 80% of all the material used is from the polyethylene family:

Linear low-density polyethylene (LLDPE)

Cross-linked polyethylene (PEX)

Low-density polyethylene (LDPE)

High-density polyethylene (HDPE)

Regrind

Other compounds are PVC plastisols, nylons and polypropylene

The order of materials most commonly used by industry is:

Polyethylene

Polypropylene

Polyvinyl chloride

Specification

|

item

|

value

|

|

Place of Origin

|

China

|

|

|

Shandong

|

|

Brand Name

|

Jinxiu

|

|

Condition

|

New

|

|

Video outgoing-inspection

|

Provided

|

|

Machinery Test Report

|

Provided

|

|

Warranty of core components

|

2 years

|

|

Core Components

|

PLC, Engine, Gear

|

|

Voltage

|

220V/380V/440V

|

|

Power

|

15-75KW

|

|

Dimension(L*W*H)

|

21.7m*18.6m*6.6m

|

|

Weight

|

10000

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

Automatic

|

|

Applicable Industries

|

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Construction works , Energy & Mining, Other

|

|

Showroom Location

|

None

|

|

Customization

|

Yes

|

|

Processing material

|

Polyethylene, PE

|

|

Scope of use

|

Forming of large and medium-sized plastic hollow products

|

|

Forming method

|

Rotary forming

|

|

Motor power

|

55kW

|

|

Voltage

|

380v

|

|

Working volume

|

20m ³

|

|

Working temperature

|

280 degrees Celsius

|

|

Heating power

|

30kw

|

|

Feed inlet diameter

|

3000mm

|

Packing & Delivery

Products are tailored to customers, transport, packaging, etc. Several options are available for customers to choose

Product LWH reference only not as the actual size, weight according to the size of the material that you use to calculate the actual considerations do

Hot Searches