The machine will automatically produce the design for the house to be installed, simply by setting it up in CAD software and inputting it into the machine. The structures that need to be used are roll formed according to different sizes and styles. After starting production one by one based on this data, a code is also ejected on each section to facilitate the installation and erection. The machine standard production speed could be 300-900meter per hour.

- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.35-1.0mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KINGREAL

-

Voltage:

-

380v as your reuqired

-

Dimension(L*W*H):

-

4.7m * 1.0.2m * 1.5m

-

Weight:

-

6000 kg

-

Feeding width:

-

40-150mm

-

Product name:

-

LGS house frame roll forming machine

-

Usage:

-

Metal ceiling production

-

Raw material:

-

Gi Steel, Aluminum

-

Thickness:

-

0.3-1.0mm

-

Roller material:

-

Cr12 Steel quenched

-

Shaft material:

-

High Grade No.45 Forged

-

After-sales Services Provided:

-

Engineers

-

System language:

-

Multilingual

-

Machine inspection:

-

Online inspection

Quick Details

-

Type:

-

Roll forming machine

-

Tile Type:

-

Steel

-

Production Capacity:

-

100m/min

-

Rolling thinckness:

-

0.35-1.0mm

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

KINGREAL

-

Voltage:

-

380v as your reuqired

-

Dimension(L*W*H):

-

4.7m * 1.0.2m * 1.5m

-

Weight:

-

6000 kg

-

Feeding width:

-

40-150mm

-

Product name:

-

LGS house frame roll forming machine

-

Usage:

-

Metal ceiling production

-

Raw material:

-

Gi Steel, Aluminum

-

Thickness:

-

0.3-1.0mm

-

Roller material:

-

Cr12 Steel quenched

-

Shaft material:

-

High Grade No.45 Forged

-

After-sales Services Provided:

-

Engineers

-

System language:

-

Multilingual

-

Machine inspection:

-

Online inspection

Products Description

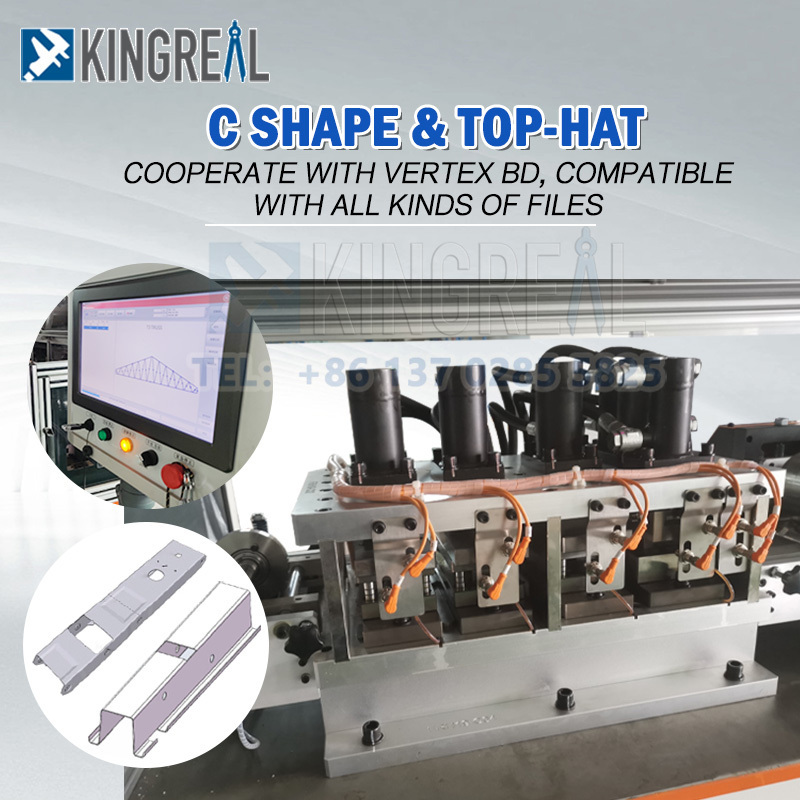

Light Steel Production Line L/Hat/U shape Profile Frame Roll Forming Machine

The production line could combine decoiler, strengthener, punching machine, roll forming machine, code inkjet machine, shearing machine, automatic control system. Running by hydraulic system and electronic system.

LGS house frame is easy to build a good quality house which is good for environment with earthquake resistant. The structural components produced in this way are quicker to construct, have a longer resistance life and are more environmentally friendly. It can significantly reduce the construction cycle time and increase construction efficiency

|

Item

|

Detail

|

|

Applicable Industries

|

Manufacturing Plant

|

|

Size

|

89,120,140 as customer required

|

|

Design software

|

Branded famous CAD software as your reuqired

|

|

Standard production speed

|

300-900m/h

|

|

Maximum production speed

|

50-60m/min

|

|

Automatic Grade

|

Automatic

|

|

Voltage

|

380V or customized as customer's request

|

|

Total Power

|

11kw

|

|

Machine size

|

4.7m * 1.0.2m * 1.5m

|

|

Machine weight

|

4600kg

|

|

Warranty

|

1 Year

|

|

Key Selling Points

|

High Productivity

|

|

Thickness of the plate

|

0.7-1.2mm

|

|

Section size

|

C89, C120, C140, or as your required

|

|

Suitable material

|

G350 / G550 galvalume steel

|

|

Usage

|

Making Light gauge steel frame for villa house

|

Applications

LGS is the fashion house frame construction solution. Use the CAD to design the house frame drawings and put data into the machine system, then the machine will produce the frame components automatically. The profiles it produce is easy to install. The LGS framing increase the efficient about house construction to next level.

Product Features

The LGS framing machine install our self-developed control system. Combine with the high-quality industrial level computer

processors that the machine can produce with good compatibility with CAD software.

processors that the machine can produce with good compatibility with CAD software.

After a long time of serving our customer, we have a library of high-quality design documents. We can provide our customer, the

standard profiles CAD program. For you customized profiles, we can provide the design CAD program service with extra cost. No

worries after you buy the machine.

Rigorous workmanship, products from materials to workmanship. strict technology, mature technology after strict inspection. Durable structure for stable production everywhere, making the work more efficient and safer. Can be combined with a mobile trolley for production on construction sites.

Related products

Hot Searches