* 24 hours professional technical consultation.

* View our Factory.

* Specification presentation.* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery online or overses.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

11-280KW

-

Weight:

-

1200

-

Dimension(L*W*H):

-

Selection

-

Description:

-

Solid-liquid Separation Machine

-

Discharge type:

-

Spiral Screw Discharge

-

Keyword:

-

Centrifugal Decanter LW 250

-

MOC:

-

SS304/SS316/DDS etc.

-

Application:

-

wastewater treatment

-

Feature:

-

High Efficiency

-

Control system:

-

PLC control

-

Motor:

-

Double Motor

-

Operation:

-

Automatical Continuous

-

Certification:

-

ISO/CE

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Hanpu

-

Voltage:

-

220/380/440/460V

-

Power:

-

11-280KW

-

Weight:

-

1200

-

Dimension(L*W*H):

-

Selection

-

Description:

-

Solid-liquid Separation Machine

-

Discharge type:

-

Spiral Screw Discharge

-

Keyword:

-

Centrifugal Decanter LW 250

-

MOC:

-

SS304/SS316/DDS etc.

-

Application:

-

wastewater treatment

-

Feature:

-

High Efficiency

-

Control system:

-

PLC control

-

Motor:

-

Double Motor

-

Operation:

-

Automatical Continuous

-

Certification:

-

ISO/CE

Product Description

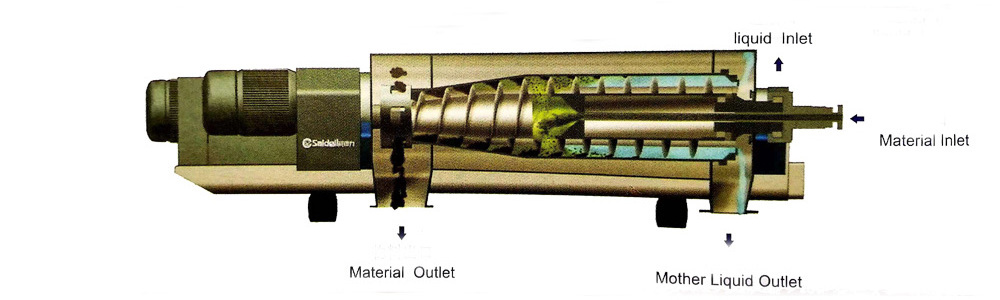

LW Sedimentation Centrifuge is a horizontal, continuously working and continuously spiral discharging sedimentation centrifuge. It is used in a variety or industries for separating all kinds of solid liquid suspension, defecating liquid phase with graded grains, and dehydrating sludge.

|

|

Main motor power(kw)

|

Processing capability(m³/h)

|

|

LW-250*1000

|

11

|

0.5-3

|

|

LW-350*1460

|

22

|

3-12

|

|

LW-450*1800

|

30-45

|

6-20

|

|

LW-520*2130

|

45-75

|

12-30

|

|

LW-650*2275

|

75-110

|

25-35

|

|

LW-720*2665

|

110-160

|

45-100

|

|

LW-900*2700

|

160-220

|

50-110

|

|

LW-1000*2500

|

280

|

50-120

|

Feature

1.Continuous working,spiral discharging,high capacity.

2.Controlled by two motors,rovolving drum can be adjustable two stage separately.

3.Wide applicability for chemical,oil,foodstuff,pharmacy industries and green industry in which solid-liquid separation is required.

4.Suitable for various products,capable for separating wide ranging solid phase grains(0.002-2mm),especially when separating solid phase has different size grains.

Application

|

Polyoxyethylene resin

|

Sulphate

|

Diatomite

|

Starch

|

|

Soy Protein

|

Peanut protein

|

Fruit juice

|

Ammonium acid

|

|

Barium carbonate

|

Barium sulfate

|

Lit powder

|

Titanium dioxide

|

|

Ore

|

China clay

|

Vegetable oil

|

Citric acid

|

|

Waste oil purification

|

Washing water purification

|

Distiller's grains

|

Animal fat

|

|

Blood meal

|

Power plant sludge

|

Printing and dyeing sludge

|

Paper sludge

|

|

Weather desulfurization sludge

|

Power plant sludge

|

Activated sludge

|

Ammonia sludge

|

|

Car wash sludge

|

Sludge drilling mud

|

Coal flotation waste

|

Cryolite flotation liquid

|

Working Principle

The machine starts and speeds up automatically.When the proper working condition are met and the revolving drum reaches the feeding speed,the feeding valve opens and allows suspension which will be separated to enter into the product compartment of the spiral feeder through the feeding pipe.After the preliminary speed-up,the suspension passes the outlet of compartment and into the drum.Because of centrifugal force,the suspension in the drum is quickly divided into two phases;the heavier solid phase deposits to the inner wall of the drum and driven by the differential gear which results in the non-cynchronous movement between the spiral feeder and the drum.the solid phase will be transferred into the small end for further dehydration and finally discharged through solid phase outlet.The separated liquid flows out though the big end or will be driven out by centrifugal pump.

Detailed Images

Exhibition

Company Introduction

Jiangsu Hanpu Mechanical Technology Co., Ltd. is a project engineering company jointly established by Jiangsu Saideli

Pharmaceutical Machinery Co., Ltd., Jiangsu Zhongyi Environmental Technology Co., Ltd., FERREO A/S in Denmark, Shanghai Jiaotong University and Nanjing Kingreat Machinery Co., Ltd. Hanpu main projects include but are not limited to: MVR evaporation system, powder washing salt and vacuum salt production project, oil tank sludge cleaning project, landfill leachate treatment project, plant/animal oil processing production line, urban wastewater treatment project, various wastewater treatment projects, and CBD oil extraction production line. Technical support and transfer of API product technology package. The main products are centrifuge series, multi-effect and MVR evaporation and crystallization equipment, laser welding heat transfer board, lithium battery material mixing equipment, pressure vessel and titanium, zirconium, nickel, and other non-standard special equipment.

Pharmaceutical Machinery Co., Ltd., Jiangsu Zhongyi Environmental Technology Co., Ltd., FERREO A/S in Denmark, Shanghai Jiaotong University and Nanjing Kingreat Machinery Co., Ltd. Hanpu main projects include but are not limited to: MVR evaporation system, powder washing salt and vacuum salt production project, oil tank sludge cleaning project, landfill leachate treatment project, plant/animal oil processing production line, urban wastewater treatment project, various wastewater treatment projects, and CBD oil extraction production line. Technical support and transfer of API product technology package. The main products are centrifuge series, multi-effect and MVR evaporation and crystallization equipment, laser welding heat transfer board, lithium battery material mixing equipment, pressure vessel and titanium, zirconium, nickel, and other non-standard special equipment.

After Sales Service

Related Products

FAQ

1. Do you have OEM service?

Do you supply the parts?

Yes, we do, as long as you provide us your drawing and detailed requirements.

2. How can we easily find out the most fit centrifuges?

We have experienced engineer team to help you make the model selection, as long as you provide us the detailed processing material characteristics.

3. Will you dispatch technicians for installation and commissioning?

Yes, we can, we do lots of service, please refer to our after sales part.

4. What is your advantage compared with your competitors?

Quality and experience. We are the top centrifuge supplier in China, our designs and structures are similar to world leader Alfa Laval, Westfaliar, Flottweg etc.

5. How do you protect the quality?

My factory is a state owned enterprise with more than 100 years experience, strict operation policy is performed, advanced processing machines guarantee the precision of all components, workers with operation license, parts get multiprocessing, transmission&electrical parts are of international famous brand. Series of test and inspection are done in the whole producing stage.

6. Can we visit your end user or contact them?

Yes,users are in domestic and abroad, we can provide you the name list. You can go there or contact to get more info.

Hot Searches