- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dingchen Machinery

-

Voltage:

-

380V/440V

-

Power:

-

400kw

-

Dimension(L*W*H):

-

15*6.5*5.5meter

-

Weight:

-

92 kg

-

Name:

-

Toilet Paper Making Machine

-

Output paper:

-

Toilet tissue paper

-

Raw material:

-

recycle papers

-

After Warranty Service:

-

Spare parts

-

After-sales Service Provided:

-

Online support

Quick Details

-

Production Capacity:

-

5000kgs per 24hours

-

Product Type:

-

Toilet Paper Making Machine

-

Processing Type:

-

Toilet Paper Making Machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Dingchen Machinery

-

Voltage:

-

380V/440V

-

Power:

-

400kw

-

Dimension(L*W*H):

-

15*6.5*5.5meter

-

Weight:

-

92 kg

-

Name:

-

Toilet Paper Making Machine

-

Output paper:

-

Toilet tissue paper

-

Raw material:

-

recycle papers

-

After Warranty Service:

-

Spare parts

-

After-sales Service Provided:

-

Online support

Products Description

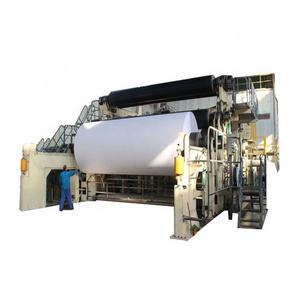

1880mm 5 TPD Paper Recycling Machine

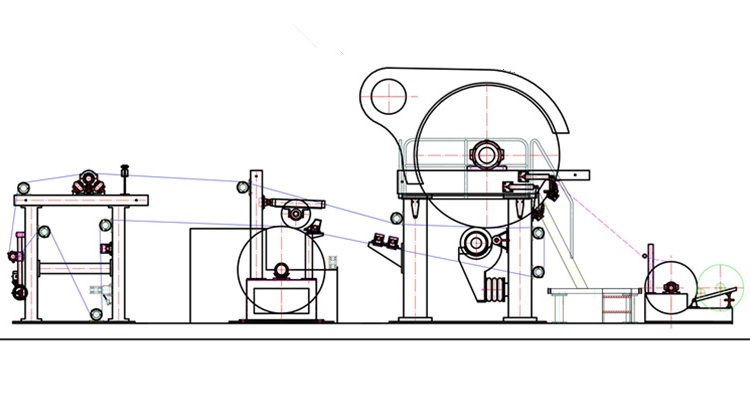

Technical parameter:

1.Output paper: toilet tissue paper

2.Raw material:waste office paper,waste books,white paper scrap from printing factory

3.Capacity: 5 tons per day

4.Net paper width: 2000mm

5.Rail gauge: 2800mm

6.Drive way: AC frequency converter speed adjusting, section drive.

7.Layout type:right hand machine.

Toilet paper making machine which recycle waste white papers to be new white toilet tissue paper roll

through pulping,cleaning,forming,drying,converting.

|

No.

|

Item

|

Function

|

||

|

Pulp making section

|

|

|

||

|

1

|

High Consistency Hydra-pulper

|

To break the waste paper into pulp and drop down the impurity and ink

|

||

|

2

|

High frequency vibrating screen

|

To separate and remove the small impurity(such as broken plastic tape,staples,etc) in the pulp through vibrating

|

||

|

3

|

Bleacher

|

To whiten the pulp through bleaching

|

||

|

4

|

Pulp refiner

|

To grind pulp fiber

|

||

|

5

|

Low concentration pulp cleaner

|

To remove the sand and tiny impurity in the water and pulp

|

||

|

6

|

Centrifugal screen

|

To screening pulp fiber

|

||

|

7

|

Impeller

|

To stir the pulp and make sure the pulp and water mixed well

|

||

|

8

|

Pulp pump

|

To provide the pulp for the needed machine

|

||

|

Paper making section

|

|

|

||

|

9

|

Cylinder mold part

|

To forming wet paper web

|

||

|

10

|

Dryer section part

|

To dry wet paper

|

||

|

11

|

Winding part

|

To reeling output paper be a jumbo paper roll

|

||

|

12

|

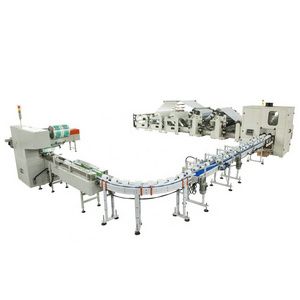

Paper converting part

|

To rewinding,perforating,cutting and packing

|

||

Details Images

Recommend Products

Product packaging

Carefully Packing,Reliable Fixing for Safety Delivery to Each Client

Hot Searches