- Product Details

- {{item.text}}

Quick Details

-

MF:

-

C3H5NO)n

-

EINECS No.:

-

208-750-2

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Evergreen

-

Model Number:

-

K909CC

-

Appearance:

-

light yellow viscous liquid

-

Viscosity, 25℃:

-

0.8-1.2

-

Solid Content:

-

63-70

-

Gel time, 25℃:

-

3.5-7

-

Acid Value(mgKOH/g):

-

13-21

-

Thermal stability at 80℃:

-

≥24

-

Net weight:

-

220kg

-

packaging:

-

metal barrel

Quick Details

-

CAS No.:

-

25608-12-2

-

Purity:

-

100%

-

Other Names:

-

unsaturated polyester resin

-

MF:

-

C3H5NO)n

-

EINECS No.:

-

208-750-2

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Evergreen

-

Model Number:

-

K909CC

-

Appearance:

-

light yellow viscous liquid

-

Viscosity, 25℃:

-

0.8-1.2

-

Solid Content:

-

63-70

-

Gel time, 25℃:

-

3.5-7

-

Acid Value(mgKOH/g):

-

13-21

-

Thermal stability at 80℃:

-

≥24

-

Net weight:

-

220kg

-

packaging:

-

metal barrel

Product description

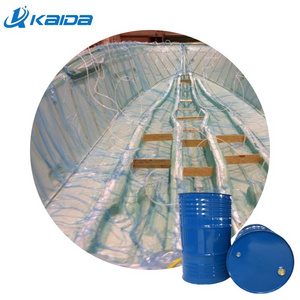

1) It is a solution of o-benzene type unsaturated polyester resin in styrene, with accelerant and thixotropic agent added

Low reaction exothermic temperature, good construction performance. It has good water resistance and excellent mechanical strength, which is suitable for FRP fishing

Ships, yachts, lifeboats and other large shaped products;

2) It has been approved by Lloyd's, China Classification Society and Japan Maritime Association;

3) TC-K909CC (n) w is suitable for winter use from November to February (below 15 ℃);

TC-K909CC (n) m belongs to spring and autumn type, which is suitable for March to May and September to October (15-25 ℃);

TC-K909CC (N) S belongs to summer type, which is suitable for June to August (above 25 ℃);

TC-K909CC-W, TC-K909CC-M and TC-K909CC-S contain wax and have air dryness;

TC-K909CC-(N)W, TC-K909CC-(N)M and TC-K909CC-(N)S do not contain wax and are non air drying.

Technical index of liquid resin

| Item | TC-K909CC-(N)W | TC-K909CC-(N)M | TC-K909CC-(N)S | remarks |

| viscosity(Pa.S) | 0.15-0.29 | 0.26-0.40 | 0.30-0.50 | test method |

| Thixotropy index | 1.2-2.8 | 1.2-2.8 | 1.2-2.8 | JIS-K-6901 |

| Gelation time*(min.) | 10.0-24.0 | 15.0-45.0 | 25.0-55.0 | *55%MEKP:1% |

Physical properties of casting body and FRP

| Item | Measured value | Test method | |

| Casting body | FRP | ||

| proportion | 1.2 | -- | JIS-K-7112 |

| Shrinkage rate (%) | 7.8 | -- | Recalculation based on liquid / solid ratio |

| Hot deformation temperature (℃) | 65 | -- | JIS-K-7207 |

| Water absorption rate (%) | 0.22 | 0.17 | JIS-K-7209 |

| Barco hardness (hbi-a) | 42 | 45 | JIS-K-7060 |

| Tensile strength (MPA) | 62 | 107 | JIS-K-7113 |

| Tensile modulus (MPA) | 3900 | 8800 | JIS-K-7113 |

| Tensile elongation (%) | 2 | -- | JIS-K-7113 |

| Bending strength (MPA) | 120 | 191 | JIS-K-7203 |

| Bending modulus (MPA) | 3800 | 6800 | JIS-K-7203 |

| Compressive strength (MPA) | 137 | 142 | JIS-K-7208 |

| Hammer impact strength (kJ / m2) | 2.1 | -- | JIS-K-7111 |

| V-type impact strength (kJ / m2) | -- | -- | JIS-K-7110 |

| Glass fiber content (%) | -- | 30.1s | JIS-K-7052 |

Remarks:

1) Curing agent dosage: 55% MEKP 1%;

2) Casting body: 3mm thick, post curing at 110 ℃ for 2 hours;

3) FRP: 3 layers of chopped mat (450g / m2), and then cured at 40 ℃ for 16 hours.

|

Step1: entering raw materials. Feed the raw materials from the tanker truck into the raw material storage tank.

|

|

|

Q: I want to find the most suitable resin for my product.

Can you make it customized?

A: Yes,as long as it is the needs of customers,we will do our best to satisfy,please contact our customer service,introduce your company's products and requirements,we first introduce or arrange to sample the most close to the parameters of the product,after you test we'll discuss the specific modification parameters.

Q: What is your company's transportation form?

A: Samples generally deliver by international express,a large number of goods can be transported by land or water.

Q: How long is the delivery time?

A: The products in our product list are basically in stock.If the customer needs to purchase the original specifications,it will be within 1-2 weeks.If you need to arrange special packing or change product parameters,we will also help you with the production and delivery as soon as possible.

Q: Can I get a low price if I order a large quantity ?

A: Sure,The price of the Alibaba is just a reference,because of the raw material price floating is bigger,before purchasing,you need contract with our sales,according to your purchase quantity and request,we will give you the lowest price.

Q: What's shelf life of the liquid fiberglass unsaturated polyester resin 191 frp resin?

A: At least 3 months ,but if add accelerator , that is 50 days .