- Product Details

- {{item.text}}

Quick Details

-

Torque Capacity:

-

20 or OEM

-

Model Number:

-

OEM

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Wangli

-

Product name:

-

large gear shaft

-

Color:

-

Customer Requirement

-

Certification:

-

ISO

-

Diameter:

-

Min.120mm

-

Length:

-

Min.500mm

-

Surface Treatment:

-

Surface Hardening or others

-

Machining Tolerance:

-

+/-0.01mm

-

Accuracy Grade:

-

6~8 or customer request

-

Heat Treatment:

-

Q+T

-

MOQ:

-

2 Piece

Quick Details

-

Weight (KG):

-

755

-

Marketing Type:

-

Hot Product 2023

-

Material:

-

alloy steel or other

-

Torque Capacity:

-

20 or OEM

-

Model Number:

-

OEM

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Wangli

-

Product name:

-

large gear shaft

-

Color:

-

Customer Requirement

-

Certification:

-

ISO

-

Diameter:

-

Min.120mm

-

Length:

-

Min.500mm

-

Surface Treatment:

-

Surface Hardening or others

-

Machining Tolerance:

-

+/-0.01mm

-

Accuracy Grade:

-

6~8 or customer request

-

Heat Treatment:

-

Q+T

-

MOQ:

-

2 Piece

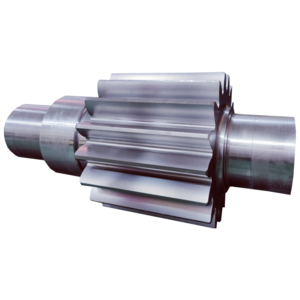

Product Name

Large helical gear shaft

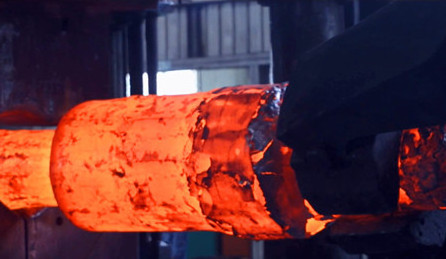

Production process

Forging

We can make relevant blanks according to the needs of customers.

Rough machining

Rough machining can cut off most of the surplus materials in a short time as possible, provide positioning precision benchmark for semi finish and finish machining, and find the blank defects in time.

Heat treatment

We strictly control the parameters of each product to ensure the accuracy.QT can adjust the properties and materials to a great extent, and its strength, plasticity and toughness are good.

Finish machining

Through finishing, we can better control the accuracy and surface roughness of products.

Related Products

Hot Searches