- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

220V

-

Power:

-

1.5kw

-

Weight:

-

25 KG

-

Dimension(L*W*H):

-

270x270x680mm

-

Product name:

-

Slurry separation soybean milk grinder

-

Capacity:

-

70 kg/h

-

screen:

-

120mesh

-

Keywords:

-

Soybean milk grinder

-

Feature:

-

soybean milk maker price

-

Machine material:

-

304 Stainless Steel

-

Function:

-

soybean milk making machine

-

After Warranty Service:

-

Video technical support

Quick Details

-

Marketing Type:

-

New Design

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HS

-

Voltage:

-

220V

-

Power:

-

1.5kw

-

Weight:

-

25 KG

-

Dimension(L*W*H):

-

270x270x680mm

-

Product name:

-

Slurry separation soybean milk grinder

-

Capacity:

-

70 kg/h

-

screen:

-

120mesh

-

Keywords:

-

Soybean milk grinder

-

Feature:

-

soybean milk maker price

-

Machine material:

-

304 Stainless Steel

-

Function:

-

soybean milk making machine

-

After Warranty Service:

-

Video technical support

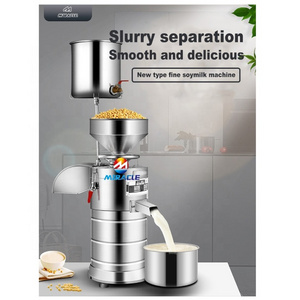

Mini 70kg/h Slurry separation soybean milk grinder

Stainless steel Soybean milk extractor/Soybean milling machine is a new type of soybean processing machinery,Which is characterized by the grinding of raw materials at the same time, pulp and slag can be

separated in the body itself.

The machine structure is reasonable, beautiful appearance, easy to operate. With a small size, light weight, low noise, the provincial staff, provincial power, stable performance, reliable quality.Easy to clean, easy to move, and other advantages;

Operating instructions

1.Soaking material:

Remove material iron, gravel and other debris; soaked with warm water to no hard core Can be. (Note: high-temperature water immersion materials easily lead to large viscosity, sub-slag effect Fruit poor).

2.Sart:

Loosen the lock nut and turn the adjustment handle in the coarse direction until it is pushed by hand Slag mouth exposed when the filter rack without block, turn the flexible start to power machine.

3.Adjust the gap:

Adjust the handle to the fine direction until you hear a slight fric- tion. Do not adjust Too small, too easy to grind the beans, blocking filter mesh, there slag belt Pulp, and significantly reduce the production efficiency, increase power consumption. Clearance is too large Slag rate is too high, the same low productivity and material waste, (empirical dataFor each kg of dry soybeans; soak for 2 kg or so, the operation by adding 2.5Kg of water; said wet weight of about 1.3 kg, the concentration of soy milk, a slag Rate, hour yield, separation and other indicators for the best value).

In order to further improve the utilization of soybean residue, can be transferred to the bean dregs water,Nephew into the hopper, repeat the processing can be.

4. Cleaning:

End of the work should be promptly cleaned filter, machine residue to ensure good

Sub-slag effect and machine health. Here's how:

1. Unscrew the fastening bolts on the feeder, remove the filter rack, moving wheel Such as

cleaning, filter must be cleaned to no clogging.

2. With a cloth to wipe the body, outside, prohibited water scouring to prevent electricity Machine

into the water.

3. In accordance with the structure of the order in accordance with the filter frame and other

relevant parts recovery, by Fastening bolts fasten; prepare next time.