- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Active vacuum brazing silver solder paste AgCuTi and AgCuInTi

-

Application:

-

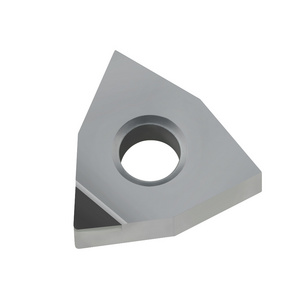

diamond single crystal or PCD vacuum welding

-

Material:

-

flux, binder, alloy powder

-

Color:

-

deep brown

-

Appearance:

-

paste

-

Quality:

-

Super

-

Brand name:

-

Yuanjie

-

Delivery:

-

within 7 days

Quick Details

-

Warranty:

-

6 months

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YJ

-

Product name:

-

Active vacuum brazing silver solder paste AgCuTi and AgCuInTi

-

Application:

-

diamond single crystal or PCD vacuum welding

-

Material:

-

flux, binder, alloy powder

-

Color:

-

deep brown

-

Appearance:

-

paste

-

Quality:

-

Super

-

Brand name:

-

Yuanjie

-

Delivery:

-

within 7 days

Active vacuum brazing silver solder paste AgCuTi and AgCuInTi Special solder paste for welding ceramic metal and diamond

Description of AgCuTi silver brazing paste.

Ag Cu Ti system solder contains "Ti" active elements.

When brazing with active solder, the protection of active elements is a very important aspect. These elements are very easy to oxidize, and can no longer react with ceramics after being oxidized.

Therefore, the vacuum degree of the furnace is required to be very high, less than 10e-2.

What is the usage of the silver brazing paste?

Brazing paste is suitable for welding between non-ferrous metals and ferrous metals such as copper and copper alloys, aluminium and aluminium alloys, steel and stainless steel, diamond and alloy cutting tools.

Copper pipes, valves, condensers and evaporators have been widely used in refrigerators, air conditioners, refrigerators and other products for welding; aluminium heat sinks and aluminium pipes, expansion valves, water tanks for automobile air conditioning; various diamond saw blades, tools, knife moulds; electric heating pipes, bathroom water heating, temperature control appliances, stainless steel utensils, electrical machinery and appliances, glasses, lighting, furniture; transformers and heating systems. Welding between copper and aluminium.

Main type of our silver brazing paste?

| Brazing paste type | AWS | Ag | Cu | Zn | Others | Melting temperature℃ | Brazing temperature ℃ | Specification |

| EBN560 | BAg-7 | 56 | 22 | 17 | 5 Sn | 618-652 | 652-760 | Cadmium-free silver solder at the lowest melting temperature has excellent fluidity and wettability, and is used for brazing of food equipment that matches the color of base metal. |

| EBN720 | BAg-8 | 72 | 28 | 779 | 779-899 | Suitable for brazing in furnace under protective atmosphere, usually for joining copper or copper alloys | ||

| EBN495 | BAg-22 | 49 | 16 | 23 | 4.5Ni 7.5Mn | 680-699 | 699-830 | Low temperature solder, good fluidity, especially suitable for brazing cemented carbide tools |

| EBN505 | BAg-24 | 50 | 20 | 28 | 2Ni | 660-707 | 707-843 | It is used to connect carbide cutters in 300-series stainless steel (mainly food processing equipment and medical equipment) and cutting tools. Nickel in solder is helpful to retard interfacial corrosion |

| EBN380 | BAg-34 | 38 | 22 | 28 | 2Sn | 649-721 | 721-843 | Good liquidity, ideal substitutes for BAg-2 and BAg-2a |

| EBN452 | BAg-36 | 45 | 27 | 35 | 3Sn | 646-677 | 677-813 | Low temperature solder, good fluidity. Used to connect ferrous and non-ferrous metal joints |

| EBN255 | BAg-37 | 25 | 40 | 33 | 2Sn | 688-779 | 779-885 | Economic brazing filler metal for brazing of steel, copper and brass; |

| Brazing Alloys | Metal content % | Solid phase temperature ℃ | Liquid phase temperature ℃ |

| Ag-Cu-Ti | 70.5-27.5-2 | 780 | 805 |

| Ag-Cu-In-Ti | 59.5-24-15-1.5 | 605 | 755 |

| Ti-Zr-Cu-Ni | 57-13-21-9 | 910 | 920 |

| Ti Zr is often used as active element in active solder. Active solder brazing is usually carried out in vacuum or high purity protective gas. | |||

PACKING of our silver brazing paste:

Normal packaging:

Other packing can be customized according to customer's requirement

| Product | Dimension | Packing |

| Brazing Alloy Rod | 500 mm | 1 kg/bag, 20 kg/box,10 kg/bag |

| Brazing Alloy Rod | 1000 mm | 5 kg/bag, 30 kg/box |

| Brazing Alloy Wire | Roll | 5 kg/roll, 10 kg/roll, 20 kg/roll |

| Brazing Alloy Sheet/Strip | All kinds | 1 kg/bag, 10 kg/box, 20 kg/box |

| Brazing Alloy Ring | All kinds | 1 kg/bag, 10 kg/box, 30 kg/box |

| Brazing Alloy Powder | 5 kg/bag, 10 kg/box, 30 kg/barrel | |

| Brazing Alloy Paste | 1 kg/can, 10 kg/barrel, 30 kg/barrel | |

| Brazing Flux Powder | 500 g/can, 500 g/bag, 20 kg/box | |

| Brazing Flux Paste | 1 kg/can, 1 kg/bag, 40kg/box | |

| Brazing Flux Paste-Auto | 1 kg/can, 1.5 kg/can, 9kg/box | |

| Brazing Flux-liqui/gas | 3 liter/barrel, 3.5 kg/barrel, 12kg/box, 200 liter/barrel |

Service of our silver brazing paste:

1.Customized products

2. Free sample

3. Brazing technology communication