- Product Details

- {{item.text}}

Quick Details

-

Return Force (kN):

-

200 kN

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Kaichuang

-

Year:

-

2023

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

3100x1800x3500mm

-

Weight (T):

-

15 T

-

Motor Power (kw):

-

18.5 kw

-

Marketing Type:

-

Hot Product 2023

-

After-sales Service Provided:

-

1 Year

-

Function:

-

Pressing

-

Application:

-

Hydraulic Press Bending Machine

-

Advantage:

-

High Efficiceny

-

Certification:

-

CE ISO

-

Feature:

-

High Sensitive

-

Automation:

-

Configurable Automated Production Line

-

Brand:

-

Kaichuang

-

Service life:

-

Ordinary Models

-

Package:

-

Wooden Case

Quick Details

-

Machine Type:

-

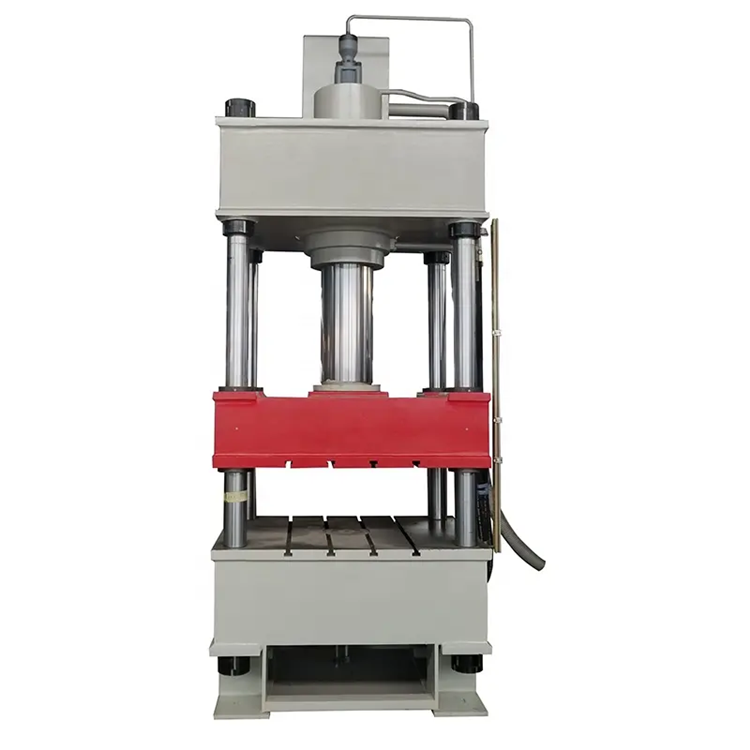

Four-column Three-beam Hydraulic Press

-

Slide Stroke (mm):

-

600, 800

-

Ejector Force (kN):

-

250-1000

-

Return Force (kN):

-

200 kN

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Kaichuang

-

Year:

-

2023

-

Voltage:

-

220V/380V/440V

-

Dimension(L*W*H):

-

3100x1800x3500mm

-

Weight (T):

-

15 T

-

Motor Power (kw):

-

18.5 kw

-

Marketing Type:

-

Hot Product 2023

-

After-sales Service Provided:

-

1 Year

-

Function:

-

Pressing

-

Application:

-

Hydraulic Press Bending Machine

-

Advantage:

-

High Efficiceny

-

Certification:

-

CE ISO

-

Feature:

-

High Sensitive

-

Automation:

-

Configurable Automated Production Line

-

Brand:

-

Kaichuang

-

Service life:

-

Ordinary Models

-

Package:

-

Wooden Case

Full semi automatic hydraulic track press

Product Description

1. It is suitable for the press fitting and stretch forming of metal and plastic products as well as the movements of coining and overprinting.

2. Hydraulic press machine mainly applies to the fields of plastic bricks, machine tool, engineering machinery, bearings, washing machine, automobile parts, motor components and powder metallurgy.

3. Hydraulic press machine is suitable for the molding of plastic products, such as DMC and BMC.

4. The machine is highly automatic, especially suitable for mass production of parts. And it can be used as assembly line with several such equipment.

Specification

Advantage

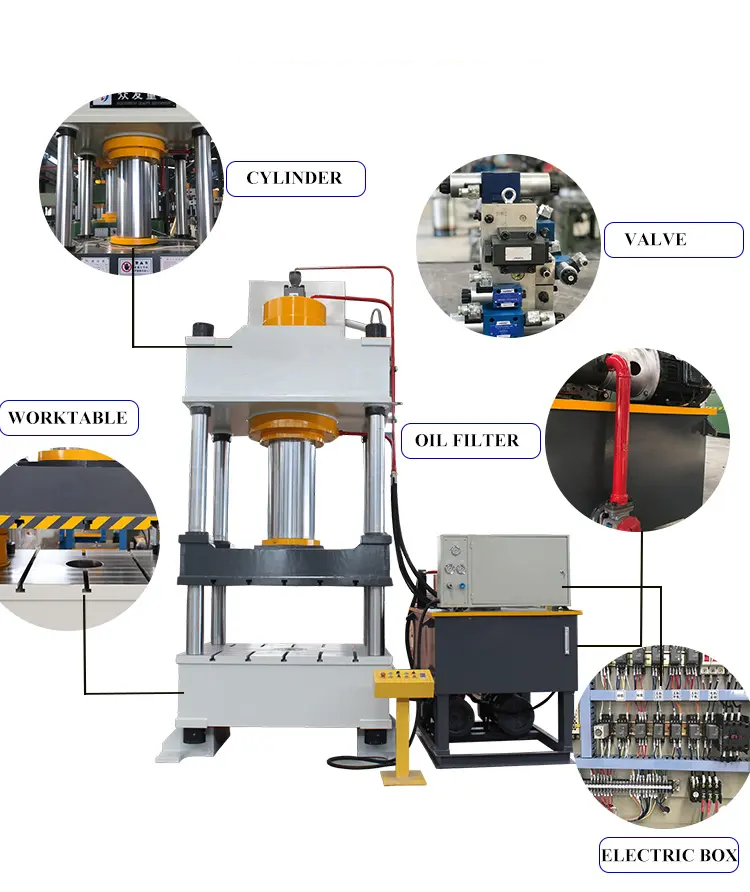

1. The hydraulic control system adopts integrated cartridge valve system and reliability, long life.

2. The hydraulic impact is small, reducing the connection between the pipe and the leak point.

3. Independent electrical control system, reliable, intuitive, easy to maintain.

4. Centralized control design, two operation modes.

5. Setup can be easily implemented.

6. Work pressure, according to the technical requirements within the scope of adjustment.

|

Model

|

100t-A

|

100t-B

|

200t-A

|

200t-B

|

315t-A

|

315t-B

|

315t-C

|

|

|

Nominal Force

(KN)

|

1000

|

1000

|

2000

|

2000

|

3150

|

3150

|

3150

|

|

|

Ejector Force

(KN)

|

250

|

250

|

350

|

350

|

630

|

630

|

630

|

|

|

Slide Stroke

(mm)

|

600

|

600

|

600

|

600

|

600

|

600

|

800

|

|

|

Ejection Stroke

(mm)

|

200

|

200

|

260

|

260

|

260

|

260

|

260

|

|

|

Maximum Working Force of Liquid

(Mpa)

|

25

|

25

|

25

|

25

|

25

|

25

|

25

|

|

|

Maximum Opening Height

(mm) |

1000

|

1000

|

1000

|

1000

|

1000

|

1000

|

1250

|

|

|

Effective Area of Table(mm)

|

700

(L-R)

|

560

(L-R)

|

800

(L-R)

|

1000

(L-R)

|

800

(L-R)

|

1000

(L-R)

|

1260

(L-R)

|

|

|

|

620

(Front and Rear Edges)

|

560

(Front and Rear Edges)

|

800

(Front and Rear Edges)

|

1000

(Front and Rear Edges)

|

800

(Front and Rear Edges)

|

1000

(Front and Rear Edges)

|

1200

(Front and Rear Edges)

|

|

|

Speed

(mm/s)

|

120

(Descent)

|

120

(Descent)

|

120

(Descent)

|

120

(Descent)

|

120

(Descent)

|

|

120

(Descent)

|

120

(Descent)

|

|

|

30

(Slow Descent)

|

30

(Slow Descent)

|

25

(Slow Descent)

|

25

(Slow Descent)

|

35

(Slow Descent)

|

35

(Slow Descent)

|

35

(Slow Descent)

|

|

|

|

75

(Ejection)

|

75

(Ejection)

|

75

(Ejection)

|

75

(Ejection)

|

75

(Ejection)

|

75

(Ejection)

|

75

(Ejection)

|

|

|

|

100

(Return)

|

100

(Return)

|

90

(Return)

|

90

(Return)

|

100

(Return)

|

100

(Return)

|

100

(Return)

|

|

|

Motor Power

(kw)

|

5.5

|

5.5

|

7.5

|

7.5

|

15

|

15

|

15

|

|

|

Model

|

400t-A

|

500t-A

|

500t-B

|

630t

|

|

Nominal Force

(KN)

|

4000

|

5000

|

5000

|

6300

|

|

Ejector Force

(KN)

|

800

|

1000

|

1000

|

1000

|

|

Slide Stroke

(mm)

|

600

|

800

|

800

|

800

|

|

Ejection Stroke

(mm)

|

260

|

300

|

300

|

300

|

|

Maximum Working Force of Liquid

(Mpa)

|

25

|

25

|

25

|

25

|

|

Maximum Opening Height

(mm)

|

1200

|

1200

|

1200

|

1200

|

|

Effective Area of Table(mm)

|

1200

(L-R)

|

1200

(L-R)

|

1400

(L-R)

|

1600

(L-R)

|

|

|

1200

(Front and Rear Edges)

|

1200

(Front and Rear Edges)

|

1400

(Front and Rear Edges)

|

1600

(Front and Rear Edges)

|

|

Speed

(mm/s)

|

120

(Descent)

|

120

(Descent)

|

120

(Descent)

|

120

(Descent)

|

|

|

35

(Slow Descent)

|

35

(Slow Descent)

|

35

(Slow Descent)

|

35

(Slow Descent)

|

|

|

75

(Ejection)

|

75

(Ejection)

|

75

(Ejection)

|

75

(Ejection)

|

|

|

100

(Return)

|

100

(Return)

|

100

(Return)

|

100

(Return)

|

|

Motor Power

(kw)

|

16

|

19

|

22

|

27

|

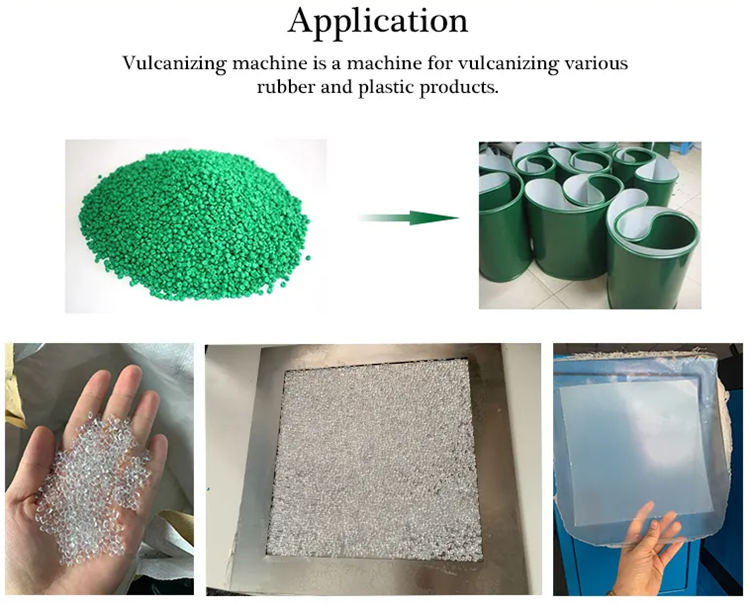

Application

1. This machine applies to cut edge for plastic or rubber products.

2. It has a wide application in many industries like packing, light industry, hardware electron and so on.

Packing & Delivery

Packing:

The normal package is wooden box. We will use pe film for packing or pack it according to customers special request.

Delivery:

Delivery within 15 days after receipt of deposit.

Our Service

Pre-sale service:

Act as a good adviser and assistant of clients,enable them to get rich and competitive from the returns of their investment.

1. Select suitable equipment model.

2. Design and manufacture products according to clients’ special requirements.

3. Train technical personnel for clients.

4. Professional suggestion for customer.

After-sale service:

Provide considerate service to minimize clients worries.

1. Provide civil engineering drawings of the equipment.

2. Free training(including installation, maintenance) to every customer.

3. Install and debug the equipment,ensure the dryer running smoothly.

4. Examine the equipment regularly.

Note: The machine can be customized according to your needs, and good products will satisfy customers. Please feel free to contact us for detailed information or special request.

Customer Feedback

Hot Searches