Retort is an indispensable processing machinery for food processing plants, through high temperature sterilization, canned food can reach a shelf life of more than one year without the use of preservatives. Whether you're making canned spam, canned sardines, or canned pets, you'll need it.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

2000 KG

-

Product name:

-

autoclave for food small continuous retort machine

-

Sterilizing way:

-

Steam 121C Sterilization

-

After-sales Service Provided:

-

Overseas Service Provided

-

Material:

-

Stainless Steel SUS304

-

Control system:

-

Automatic Control System

-

Processing Types:

-

Cannned Food

-

Function:

-

High Temperature High Pressure Sterilizing

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

ANTAI

-

Voltage:

-

380

-

Weight:

-

2000 KG

-

Product name:

-

autoclave for food small continuous retort machine

-

Sterilizing way:

-

Steam 121C Sterilization

-

After-sales Service Provided:

-

Overseas Service Provided

-

Material:

-

Stainless Steel SUS304

-

Control system:

-

Automatic Control System

-

Processing Types:

-

Cannned Food

-

Function:

-

High Temperature High Pressure Sterilizing

fish canning production line Canned fish sterilizer retort

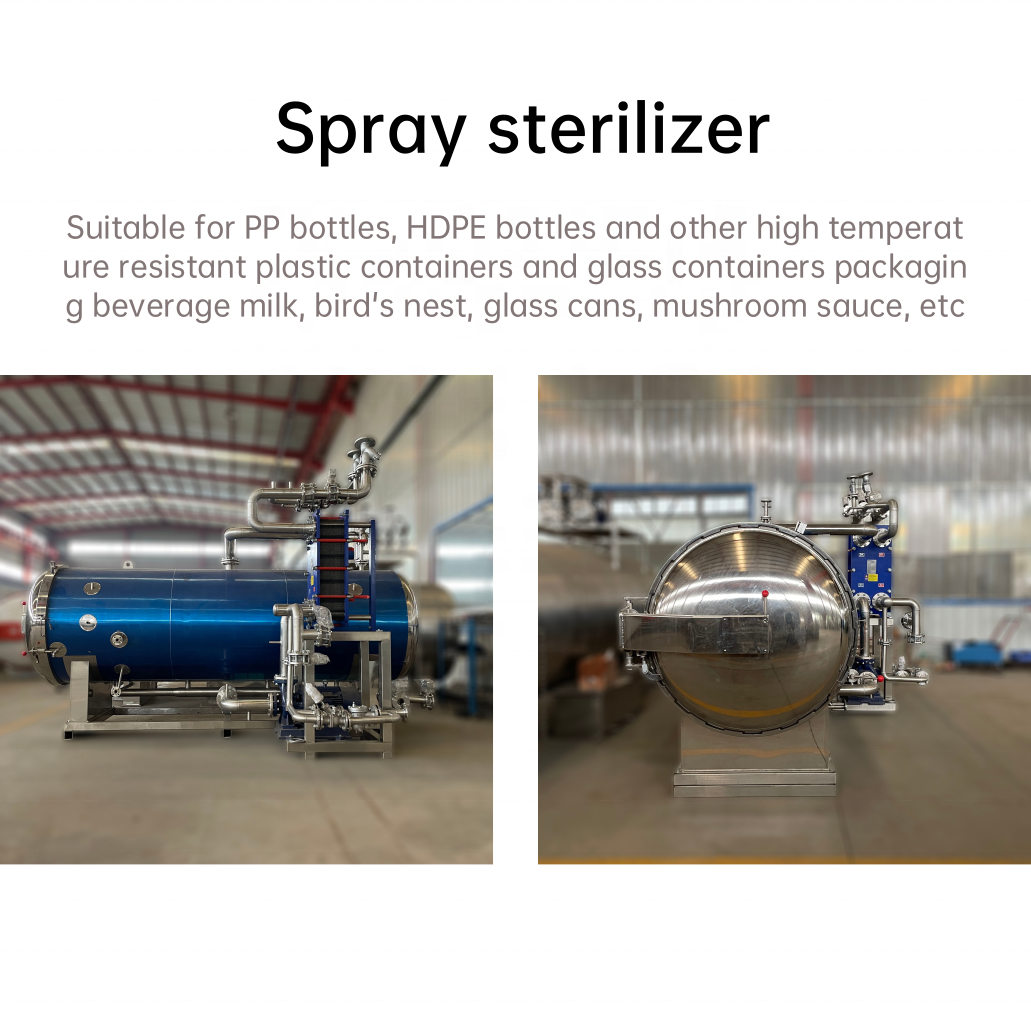

Product Application

Food packaged in tinplate cans of various sizes

Pet food, lunch meat, sardines and other food packaged in tinplate cans.

Food packaged in glass cans of various sizes

Food such as sauces, drinks, fruits, etc. packaged in glass cans

Products Description

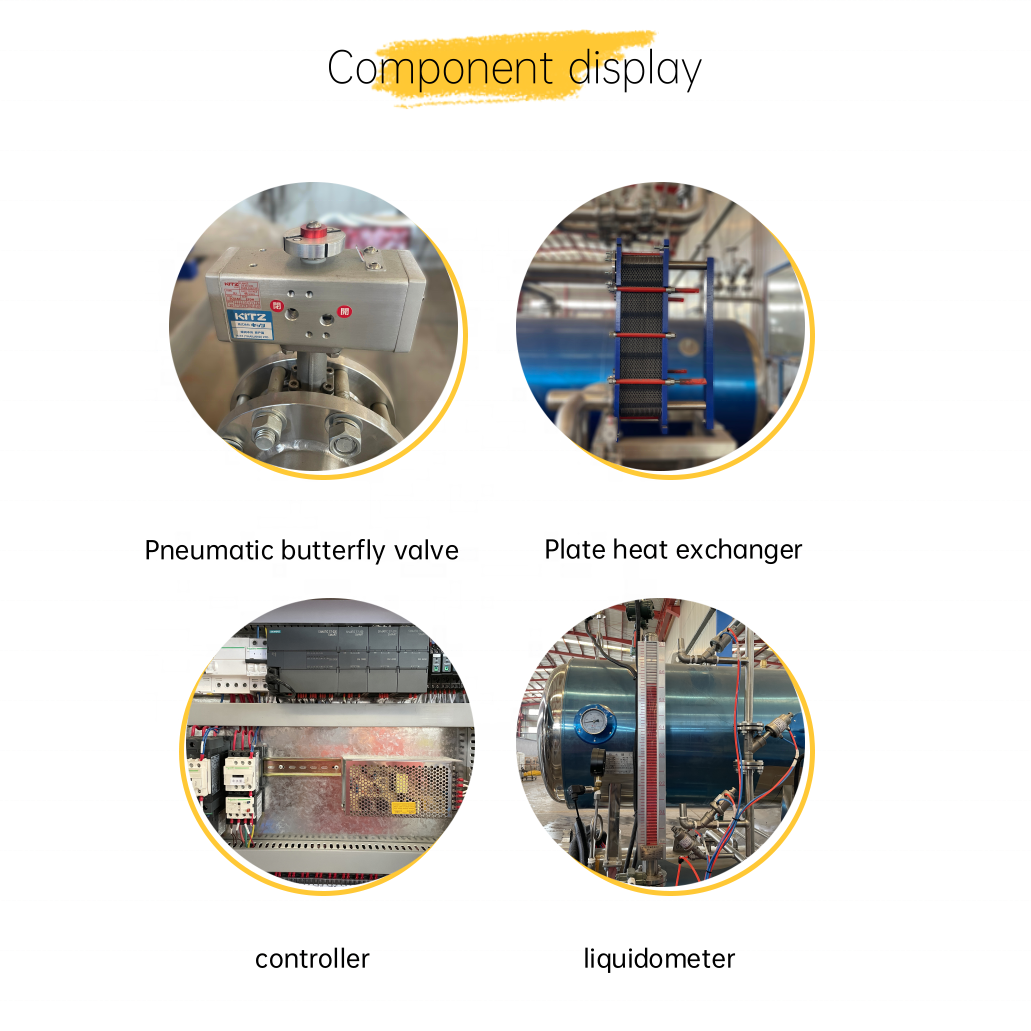

Plate heat exchanger

The key components of curve heating and cooling

Pot door interlock

Ensure the balance of internal and external air pressure when opening the sterilizer

electric heating tube

Suitable for plants without steam source

pneumatic butterfly valve

The switch valve is controlled by PLC

Boiler door cylinder

Seal the boiler door to ensure stable internal pressure.

angle seat valve

Control the amount of exhaust and compressed air

safety valve

Ensure that the pressure inside the pan does not exceed the service limit

PLC

Detect temperature and pressure and control valve switch in real time

level gauge

Instantly see the height of the liquid level in the pan

Details Images

Laser cut sheet

Using laser cutting SUS304 plate to ensure the accuracy of equipment assembly.

Automatic laser welding

The pressure tank is welded using an automatic welding robot, which is inspected four times after welding to ensure its bearing capacity.

Product Paramenters

|

|

700*1200

|

900*1800

|

1000*2400

|

1200*3600

|

|

Yield (KG)

|

100

|

200

|

500

|

800

|

|

size

|

2310*1478*1361

|

3556*1213*2800

|

4242*1500*2800

|

6258*1796x*2664

|

|

volume(m³)

|

0.6

|

1.3

|

2.1

|

4.5

|

Matching equipment

Bottle washing and blowing machine

dry machine

filling machine

RGV

palletizing robot

Loading cage

conveyor line

can seamer

Can cleaner

labeling machine

Inkjet printer

Unpacking machine

As a provider of the entire equipment line, we can customize equipment to increase your output. Please contact customer service for details.

Hot Searches