- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Chengda

-

Outer Diameter:

-

4 - 2420 mm

-

Thickness:

-

4mm-70mm

-

Length:

-

1-12M, 1-12m

-

Grade:

-

X42 X46 X52 X60

-

MOQ:

-

1 Ton

-

Packing:

-

Standard Seaworthy Packing

-

Technology:

-

Hot Rolled Cold Rolled Erw

-

Shape:

-

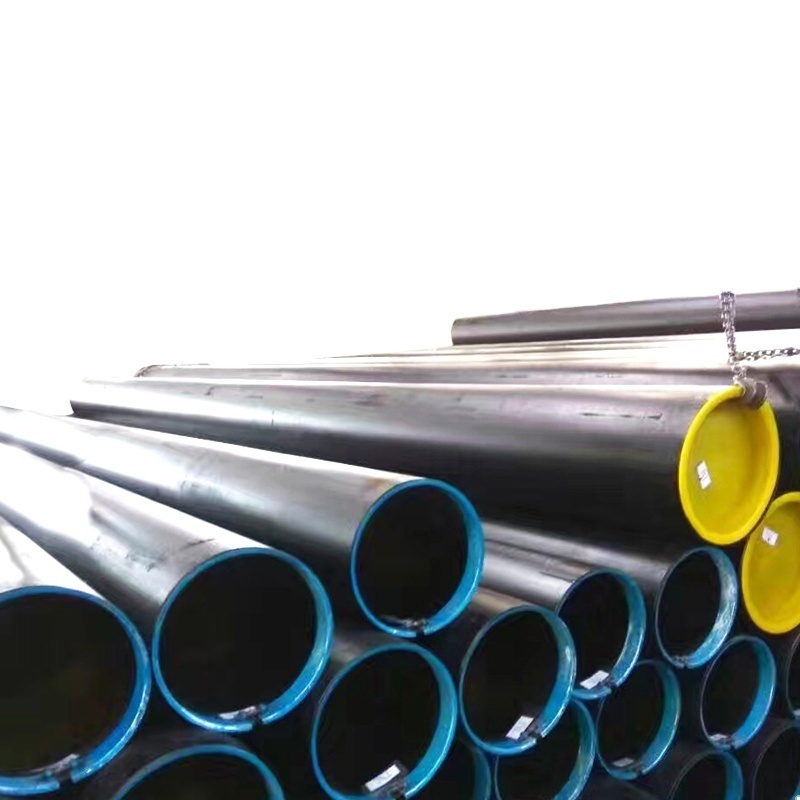

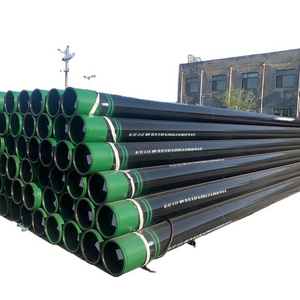

Round Pipe Tube

-

Payment terms:

-

30%TT Advance + 70% Balance

-

Usage:

-

Oil Gas Sewage Transport

-

Delivery term:

-

7-10days

-

Surface:

-

Black Painted

-

Process:

-

Hot Rolled Steel Pipe

Quick Details

-

Section Shape:

-

Round

-

Surface Treatment:

-

Hot Rolled

-

Tolerance:

-

±1%

-

Oiled or Non-oiled:

-

Non-oiled

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Chengda

-

Outer Diameter:

-

4 - 2420 mm

-

Thickness:

-

4mm-70mm

-

Length:

-

1-12M, 1-12m

-

Grade:

-

X42 X46 X52 X60

-

MOQ:

-

1 Ton

-

Packing:

-

Standard Seaworthy Packing

-

Technology:

-

Hot Rolled Cold Rolled Erw

-

Shape:

-

Round Pipe Tube

-

Payment terms:

-

30%TT Advance + 70% Balance

-

Usage:

-

Oil Gas Sewage Transport

-

Delivery term:

-

7-10days

-

Surface:

-

Black Painted

-

Process:

-

Hot Rolled Steel Pipe

|

Description of seamless steel pipe by Chengda steel

|

|

|

|

Product Name

|

ASTM AISI API 5L Seamless steel tube with Pipeline Transport

|

|

|

Standard

|

API,ASME, ASTM, EN ,BS,GB,DIN, JIS,AISI,SAE

|

|

|

Outer Dia:

|

4mm-2420mm

|

|

|

Wall Thickness

|

4mm-70mm

|

|

|

Shape

|

round

|

|

|

Materials

|

X42 X46 X52 X60

|

|

|

Inspection

|

ISO,BV,SGS,MTC

|

|

|

Packing

|

Waterproof paper, and steel strip packed. Standard Export Seaworthy Package.Suit forall kinds of transport,or as required

|

|

|

Supply Ability

|

20000 tons/month

|

|

|

MOQ

|

1metric ton,sample order accepted

|

|

|

Shipment time

|

3-15days and Depend on Customer&primes Order

|

|

|

Payments

|

T/T,L/C

|

|

Products Description

Manufacturing process

【1】 Low temperature tempering (150-250 ℃)

The microstructure obtained by low temperature tempering is tempered martensite. The purpose is to reduce the quenching internal stress and brittleness of the quenched steel on the premise of maintaining the high hardness and high wear resistance of the quenched steel, so as to avoid cracking or premature damage during use. It is mainly used for various high carbon cutting tools, measuring tools, GB / t9711.1 pipeline steel pipes, rolling bearings and carburized parts. The hardness after tempering is generally hrc58-64.

【2】 Medium temperature tempering (250-500 ℃)

The microstructure obtained by tempering at medium temperature is tempered troostite. The aim is to obtain high yield strength, elastic limit and high toughness. Therefore, it is mainly used for the treatment of various GB / t9711.1 pipeline steel pipes and hot work dies. The hardness after tempering is generally hrc35-50.

【3】 High temperature tempering (500-650 ℃)

The microstructure obtained by high temperature tempering is tempered sorbite. The heat treatment combining quenching with high-temperature tempering is commonly called quenching and tempering treatment. Its purpose is to obtain comprehensive mechanical properties with good strength, hardness, plasticity and toughness. Therefore, it is widely used in automobile, GB / t9711.1 pipeline steel pipe, machine tool and other important structural parts, such as connecting rod, bolt, gear and shaft. The hardness after tempering is generally hb200-330.

Product packaging

production process

Packaging & transportation

Hot Searches