- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

HSDZJ

-

Voltage:

-

380V

-

Power:

-

Customize

-

Dimension(L*W*H):

-

Customize

-

Weight (KG):

-

7000

-

Core box curing mode 1:

-

Triethylamine gas

-

Core box curing mode 2:

-

CO2

-

Mode of mould separation:

-

Vertical parted

-

Drive mode 1:

-

Hydraulic Drive

-

Drive mode 2:

-

Pneumatic Drive

-

Program control:

-

Fully automatic or Manual

-

Method of adding sand:

-

Automatic feed truck

-

Maximum core box size:

-

Can be customized

-

Total power of equipment:

-

According to the type of equipment

-

Weight of equipment:

-

According to the type of equipment

Quick Details

-

Place of Origin:

-

Shandong, China

-

Machine Type:

-

Casting Machinery

-

Marketing Type:

-

Hot Product 2022

-

Brand Name:

-

HSDZJ

-

Voltage:

-

380V

-

Power:

-

Customize

-

Dimension(L*W*H):

-

Customize

-

Weight (KG):

-

7000

-

Core box curing mode 1:

-

Triethylamine gas

-

Core box curing mode 2:

-

CO2

-

Mode of mould separation:

-

Vertical parted

-

Drive mode 1:

-

Hydraulic Drive

-

Drive mode 2:

-

Pneumatic Drive

-

Program control:

-

Fully automatic or Manual

-

Method of adding sand:

-

Automatic feed truck

-

Maximum core box size:

-

Can be customized

-

Total power of equipment:

-

According to the type of equipment

-

Weight of equipment:

-

According to the type of equipment

Product Overview

Z94L Series Automatic Core Shooting Machine

Z94L series

is a high efficiency Vertical parting cold box core shooting machine This machine uses cold core box resin sand, shotsand into the mold after the injection of triethylamine gas or CO2 gas,so that resin sand instant curing to get the core, themaximum core weight can reach 100kg.

The machine is driven by a combination of pneumatic and hydraulic,the hydraulic cylinder uses

overflow valve and buffer valve, which can make the machine run fast and smoothly. Positioning by proximity switch or motor signal can make the working table or sand bucket run accurately. Sand shooting and blowing amine mechanism with large flow pressurized air source, can make the cold core box coated sand reach every corner of the mold, gas is fully circulating, fast solidification of the sand core.

Cold core box method does not need electric heating, low energy consumption, short curing time, high efficiency.Widely used inengine, pump valve, railway and aerospace industries.

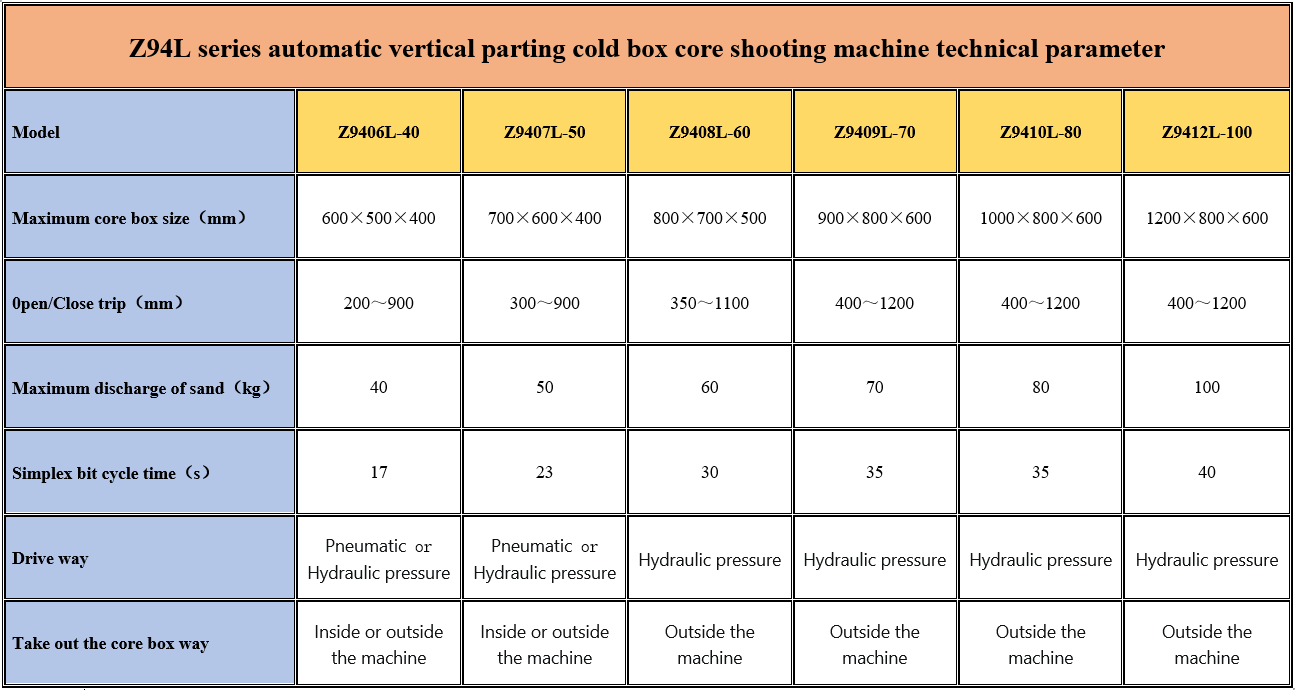

Product Specifications

Product Advantages

1.Curing Mode:

This machine is suitable for cold core box resin sand through triethylamine or CO2 gas catalyzed and quickly solidified, the production of sand core or sand model, advantages of high efficiency, low cost, less initiating amount.

2 . Program Control:

2 . Program Control:

PLC and intelligent display screen to achieve parameter setting, process display, fault diagnosis, temperature display and control and other functions.

3.Operation Mode:

(1)Manual/click/automatic operation mode can be set on the smart display.

(2)Driving mode: pneumatic, hydraulic or pneumatic hydraulic combined drive, choose electromagnetic overflow air-cooled hydraulic station, and equipped with buffer device.

4.Equipment Advantage:

(1)Equipped with high performance triethylamine gas generator, high gasification efficiency, less triethylamine consumption, no need for secondary blowing amine. The core box produced is of high strength and precision, with good finish.

(2)Suitable for multi-opening core box, optional multi-direction pulling block function, can realize 2~6 direction opening mold.

(3)It has the functions of vibration feeding, pressurized sand shooting, automatic blowing amine curing, sand shooting head cleaning, mold cleaning and so on.

(4)The work table adopts linear guide rail, the sand core and the lower die are automatically moved out of the machine, the structure runs smoothly and the guidance is accurate.

(5)Guide shaft adopts high frequency hardening chrome plated hard shaft, and with efficient dust-proof sealing structure, high precision of mold closing, long service life.

(6)Adopt automatic lubrication system, each sliding friction mechanism is equipped with lubrication device, maintain the accuracy of equipment, prolong the service life.

(7)Air bag for professional welding inspection, with special equipment safety inspection certificate, equipment equipped with a complete set of air source treatment system.

5.Product Customization:

(1)Fully automatic open door closed/safety housing.

(2)Sand shot template quick change device.

(3)Core shooting machine supporting sand mixing, feeding and triethylamine flavor removal system.

This series of products can be customized according to customer requirements.

3.Operation Mode:

(1)Manual/click/automatic operation mode can be set on the smart display.

(2)Driving mode: pneumatic, hydraulic or pneumatic hydraulic combined drive, choose electromagnetic overflow air-cooled hydraulic station, and equipped with buffer device.

4.Equipment Advantage:

(1)Equipped with high performance triethylamine gas generator, high gasification efficiency, less triethylamine consumption, no need for secondary blowing amine. The core box produced is of high strength and precision, with good finish.

(2)Suitable for multi-opening core box, optional multi-direction pulling block function, can realize 2~6 direction opening mold.

(3)It has the functions of vibration feeding, pressurized sand shooting, automatic blowing amine curing, sand shooting head cleaning, mold cleaning and so on.

(4)The work table adopts linear guide rail, the sand core and the lower die are automatically moved out of the machine, the structure runs smoothly and the guidance is accurate.

(5)Guide shaft adopts high frequency hardening chrome plated hard shaft, and with efficient dust-proof sealing structure, high precision of mold closing, long service life.

(6)Adopt automatic lubrication system, each sliding friction mechanism is equipped with lubrication device, maintain the accuracy of equipment, prolong the service life.

(7)Air bag for professional welding inspection, with special equipment safety inspection certificate, equipment equipped with a complete set of air source treatment system.

5.Product Customization:

(1)Fully automatic open door closed/safety housing.

(2)Sand shot template quick change device.

(3)Core shooting machine supporting sand mixing, feeding and triethylamine flavor removal system.

This series of products can be customized according to customer requirements.

Optional product configuration

Residual sand cleaning

Triethylamine deodorizing equipment

Sand handling and feeding system

The main supporting parts brand

SIEMENS

Control System

SMC Pneumatic System

YOUKEN Hydraulic System

FAQ

Q1:

Whether the template size can be customized?

A1:

Template size can be designed according to the size of the mold.

Q2

:

How to debug the equipment?

A2

:

The equipment is debugged before leaving the factory. It has remote debugging function and can be debugged on site.

Q3

:

H

ow long is the warranty? What does it contain?

A3

:

The warranty period is one year. Free replacement of non-human damaged parts within one year, excluding wearing parts.

Similar Products

Hot Searches