- Product Details

- {{item.text}}

Quick Details

-

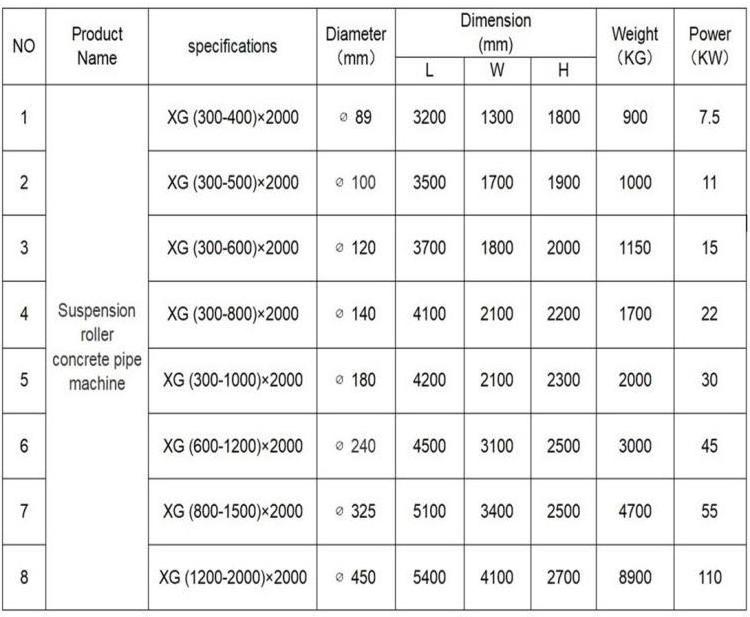

Power:

-

11KW

-

Dimension(L*W*H):

-

3500mmx1400mmx1900mm

-

Weight:

-

1000 kg

-

Raw material:

-

concrete

-

Pipe application:

-

Drainge

-

Production speed:

-

1set/5-10min

-

Key word:

-

pipe jacking machine

-

Pipe shape:

-

cylinder

-

Pipe diameter:

-

300-500mm

-

Usage:

-

Drain Pipe

-

Pipe Length:

-

0-3500mm

-

Steel grade:

-

General Carbon Steel

Quick Details

-

Pipe Material:

-

CONCRETE

-

Production Capacity:

-

1set/5-10min

-

Place of Origin:

-

Shandong, China

-

Power:

-

11KW

-

Dimension(L*W*H):

-

3500mmx1400mmx1900mm

-

Weight:

-

1000 kg

-

Raw material:

-

concrete

-

Pipe application:

-

Drainge

-

Production speed:

-

1set/5-10min

-

Key word:

-

pipe jacking machine

-

Pipe shape:

-

cylinder

-

Pipe diameter:

-

300-500mm

-

Usage:

-

Drain Pipe

-

Pipe Length:

-

0-3500mm

-

Steel grade:

-

General Carbon Steel

Product Description

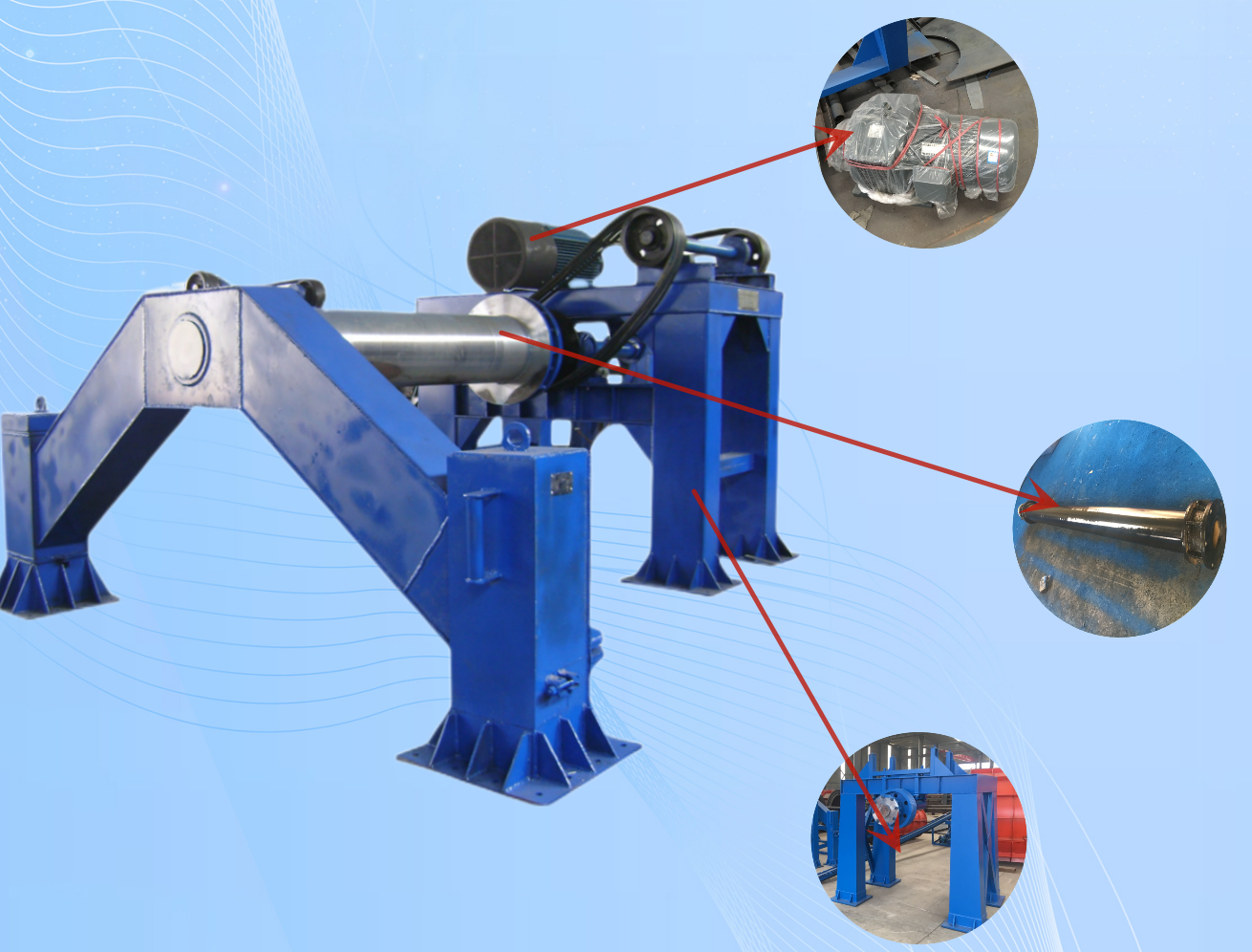

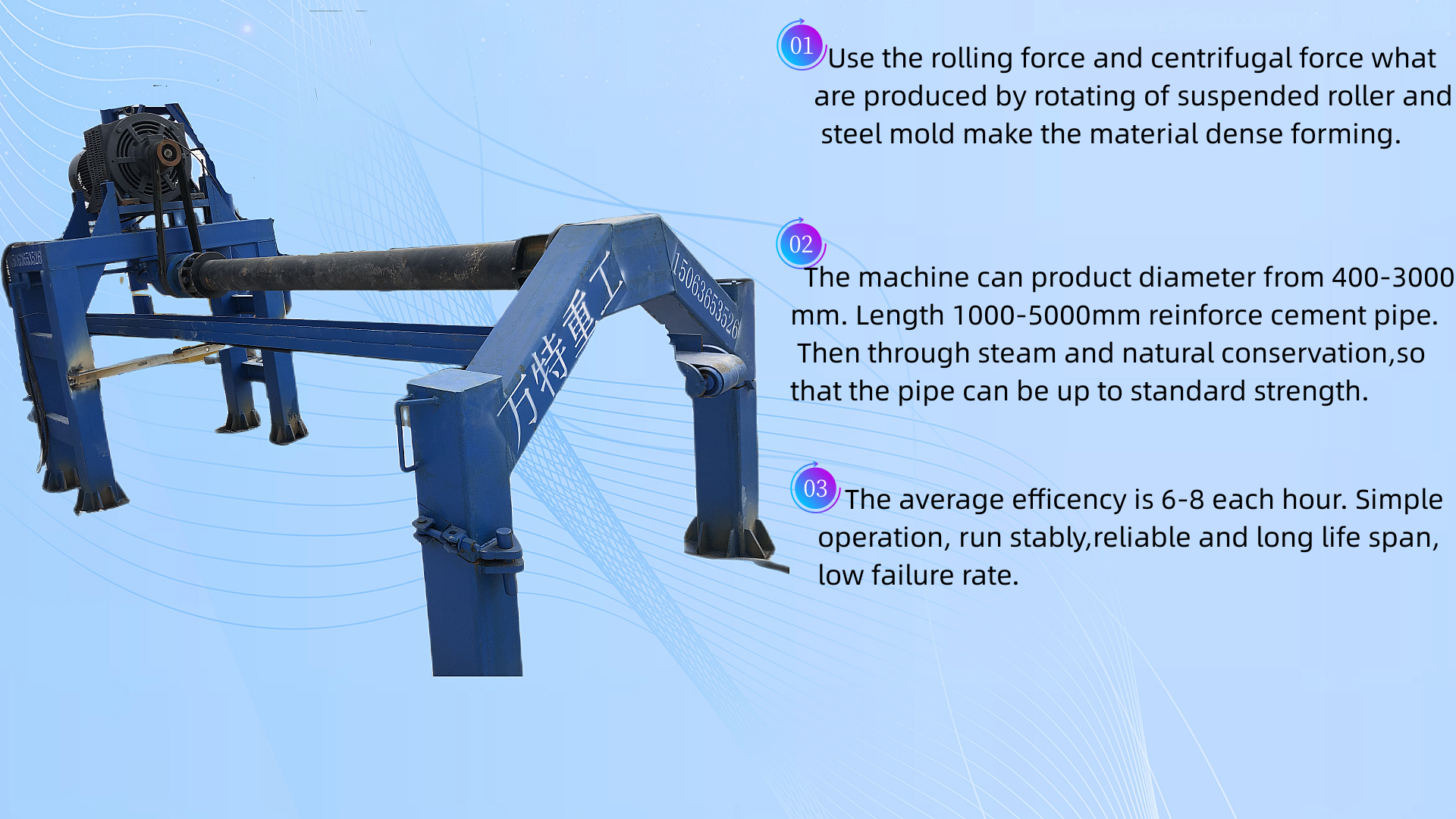

Suspended roller pipe making machine is a molding equipment that uses the suspended roller method to produce drainage pipes and water pipes. It is the main force in cement pipe production, manufacturing, and prefab rication equipment.

The machine has high production efficiency, low material consumption, low noise, easy operation, and the final product has good compactness and beautiful appearance.

Specification List

Working Principle

This machine uses the Roller to support the pipe mould, and produce the roller force to concrete in the mould.

When the roller rotate at a high speed, the concrete in the mould will spread in the inner wall of the pipe mould and form a cement pipe with the centrifugal force, and when the mould with the inner concrete pass on the roller, the concrete between the mould and the roller will be compacted solid to form a pipe.

Supporting equipment

1.Gantry crane

2. Concrete Mixing Machine

3.Concrete Batching Machine

4.Pipe Cage Welding Machine