- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V 50HZ

-

Power:

-

7.5KW

-

Dimension(L*W*H):

-

3mX1.9mX1.6m

-

Weight:

-

2500 kg

-

Marketing Type:

-

New Product 2023

-

Name:

-

paper tube machine

-

Output paper:

-

paper core,paper tube

-

Finished Products:

-

toilet tissue paper tube

-

Application:

-

toilet tissue paper

-

Raw material:

-

craft paper roll

-

cutting paper core max thicknes:

-

15mm

-

Control system:

-

PLC+Touch Screen

-

Advantage:

-

Easy Operation Aoto Cutting

-

After-sales Service:

-

Professional Technical Guidance

-

Certification:

-

CE

Quick Details

-

Production Capacity:

-

50 sets/month

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Fuyuan

-

Voltage:

-

380V 50HZ

-

Power:

-

7.5KW

-

Dimension(L*W*H):

-

3mX1.9mX1.6m

-

Weight:

-

2500 kg

-

Marketing Type:

-

New Product 2023

-

Name:

-

paper tube machine

-

Output paper:

-

paper core,paper tube

-

Finished Products:

-

toilet tissue paper tube

-

Application:

-

toilet tissue paper

-

Raw material:

-

craft paper roll

-

cutting paper core max thicknes:

-

15mm

-

Control system:

-

PLC+Touch Screen

-

Advantage:

-

Easy Operation Aoto Cutting

-

After-sales Service:

-

Professional Technical Guidance

-

Certification:

-

CE

Product Description

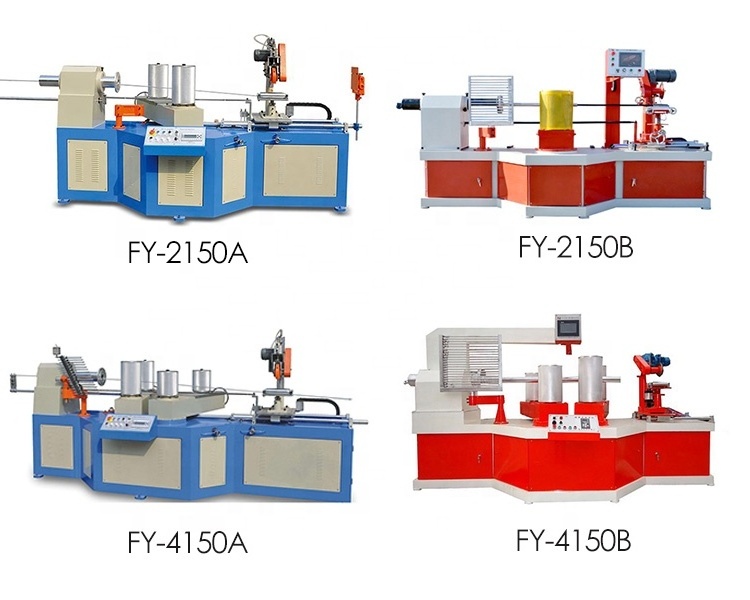

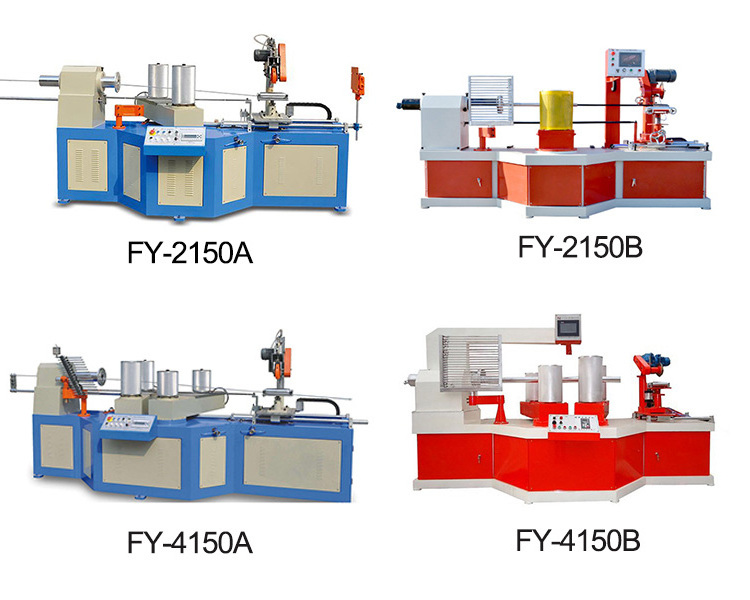

paper core tube making machine

paper core tube making machine is mainly used for making paper tube. The tubes made can be used as core of toilet paper roll.We have different model of paper core machine for choice, can make paper tube with different diameter and thickness. The finished tube can be cut and discharged automatically. Infrared and automatic transmission make cutting length more accurate.

Equipment Parameter

|

Machine Type

|

FY-2150A

|

FY-2150B

|

FY-4150A

|

FY-4150B

|

|||

|

Tube Layer

|

3~16ply

|

3~16ply

|

3~21ply

|

3~24ply

|

|||

|

Tube Diameter

|

20~100mm

|

20~150mm

|

40~200mm

|

40~250mm

|

|||

|

Tube Thickness

|

1~6mm

|

1~8mm

|

1~20mm

|

1~20mm

|

|||

|

Working Speed

|

3~15m/min

|

3~20m/min

|

3~20m/min

|

3~20m/min

|

|||

|

Power

|

4KW

|

5.5KW

|

11KW

|

11KW

|

|||

|

Host size

|

2.9*1.8*1.7m

|

2.9*1.9*1.7m

|

4*2*1.95m

|

4*2*1.9m

|

|||

|

Weight

|

2100kg

|

2800kg

|

3200kg

|

3200kg

|

|||

|

Winding head

|

Two winding heads single belt

|

|

Four winding heads double belt

|

|

|||

|

Gluing Method

|

Single/Double side gluing

|

|

|

|

|||

|

Cutting Method

|

Single round knife cutting without resistance

|

|

|

|

|||

|

Fixed length Method

|

Infrared precise length determination

|

|

|

|

|||

|

Paper Gramme

|

80-600GSM

|

|

|

|

|||

|

Control System

|

Frequency and PLC control, touch screen operation

|

|

|

|

|||

|

Voltage

|

380V,50hz or 220V,50hz

|

|

|

|

|||

|

Operator

|

1-2 Workers

|

|

|

|

|||

|

Area Space

|

20m*10m

|

|

|

|

|||

|

Reel

|

1 Set

|

|

|

|

|||

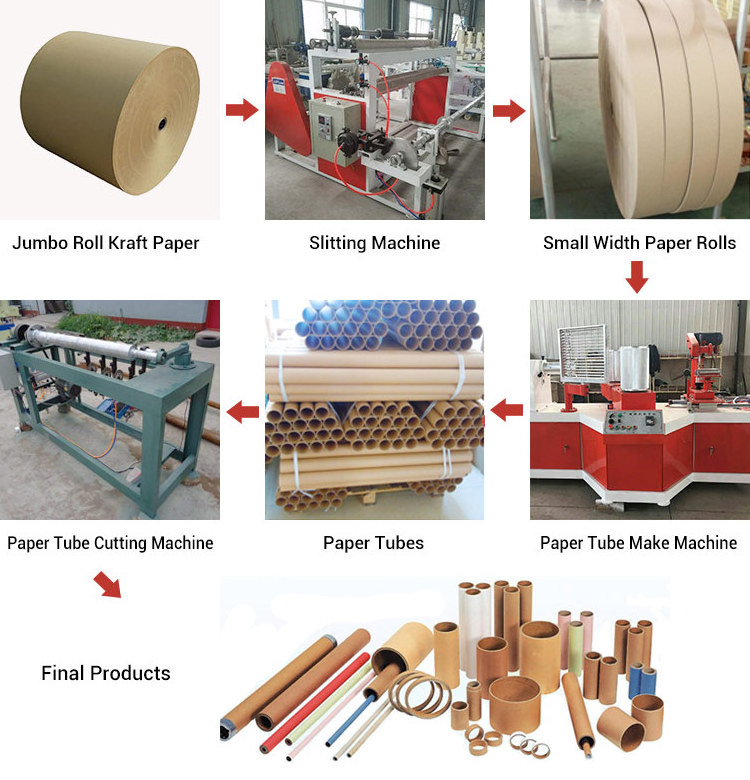

Production process

Detail Images

Features:

1. Strong versatility and high-performance configuration.

2. Using PLC logic control system touch screen man-machine interface operation.

3. The main motor adopts vector-type high-torque frequency converter for speed regulation.

4. Length of photoelectric positioning meter + computer length control, precise cutting of length.

5. Modular electrical layout design makes it more convenient and scientific to use, maintain and repair.

6. It is more convenient to operate and use (for example, it can automatically stop when the paper breaks).

7. Low noise transmission design.

8. Adopting double-sided gluing independent stainless steel glue tank, the finished paper tube has good hardness.

9 Servo screw cuts synchronously, with even gaps, suitable for the production of paper tubes of various tapes, roll paper chemical fiber tubes, and packaging paper cans.

Packaging &Delivery

Packaging:

1. Fixed all the movable parts with plastic films.

2. Polystyrene foam plate wrapped around.

3. Wrapped with tighted plastic films several circles.

4. Fixed machine on the fumigated plywood pallet with iron wire.

5. Wrapped with wooden board around and nailed on.

Shipment:

1. Sea transportation is from Qingdao port or other ports.

2. The delivery time is decided by your needed machines or machine parts. But it also follows your needs.

After Sales:

1.Highly inspecting equipments in every working procedure, quality comes first;

2. Fast Safe Delivery;

3. Assisting our clients for foundation construction of equipments;

4. Dispatching engineers to install and debug equipments;

5.Training the first-line operators one site;

6. One year warranty, we provide free machine parts within one year.

Company profile

Henan Fuyuan Machinery Manufacturing Co., Ltd

located in Zhengzhou City, Henan Province.Our factory is founded in 1984 with rich experience in paper making machine. Our main products include:egg tray machine, toilet paper rewinding machine, napkin paper machine and facial paper machine. After 36 years of development, our company has developed into a large enterprise integrating scientific research, production and trading,our factory covers an area more than 33,000 square meters, construction area more than 16,000 square meters, existing staff more than 200 workers, including 5 senior engineers, 22 engineers, and more than 38 technical staff. We are committed to provide customers with a complete solution for paper making project and paper egg tray making production line,welcome the friends to visit us over the world.

Hot Searches