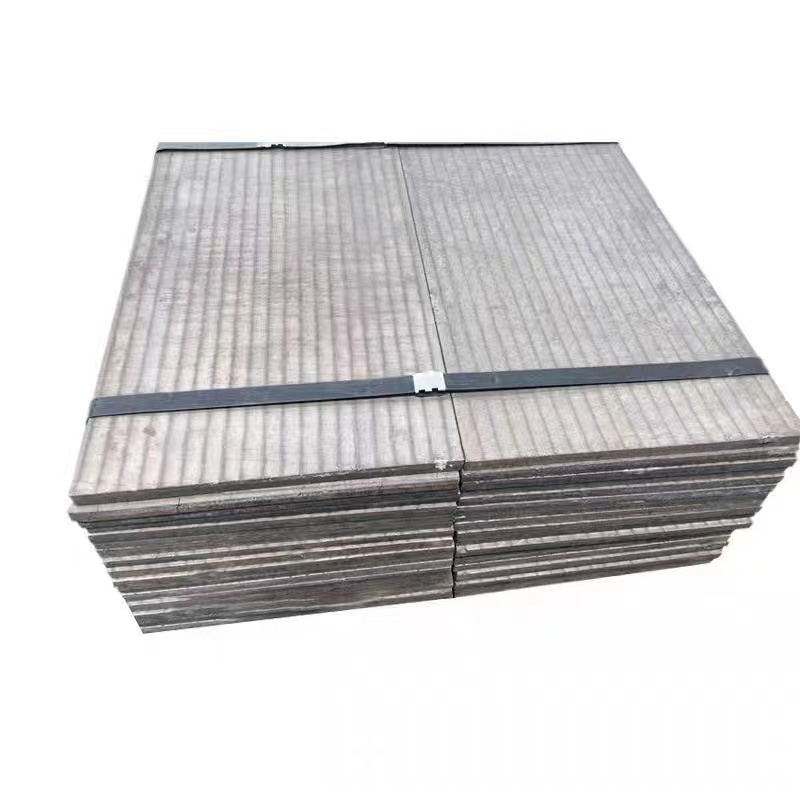

HFC hard surface surfacing can make parts have better anti-wear properties, which is better than casting or forging replacement parts. The material composition and thickness of the hard surface surfacing layer can be controlled, which can significantly improve and extend the operating efficiency and life of the equipment and has excellent economic benefits.

- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

Normally 15KG or 250kg

-

Flux Content:

-

None(custom)

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

ODM OEM

-

Model Number:

-

VTD101W-O, VTD101W-O

-

Application:

-

Cement, Metallurgical, Power, Mining , etc

-

Type/Keyword:

-

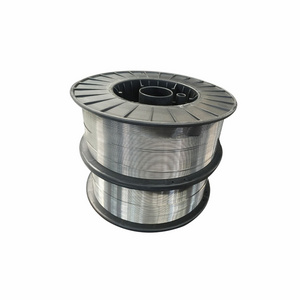

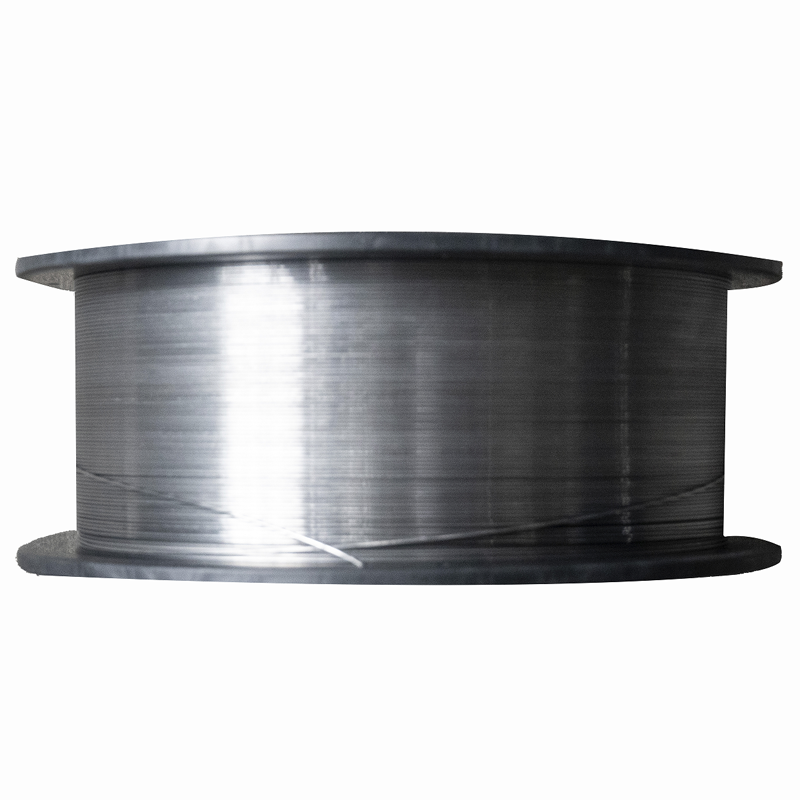

Welding wire

-

Alloy Or Not:

-

Is Alloy

-

Tolerance:

-

±1%

-

Processing Service:

-

Welding, Cutting

-

Chemical Composition:

-

C: 2.5-5.0 Cr: 22.5-27.5

-

Hardness:

-

58 - 62 HRC

-

Performance:

-

no slag, low spatter, high welding efficiency

-

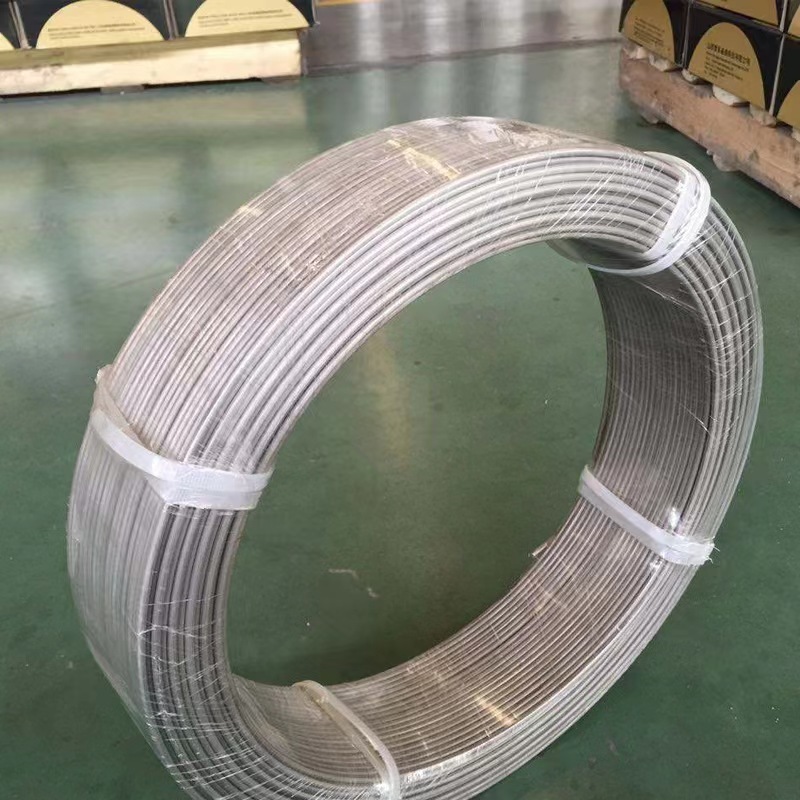

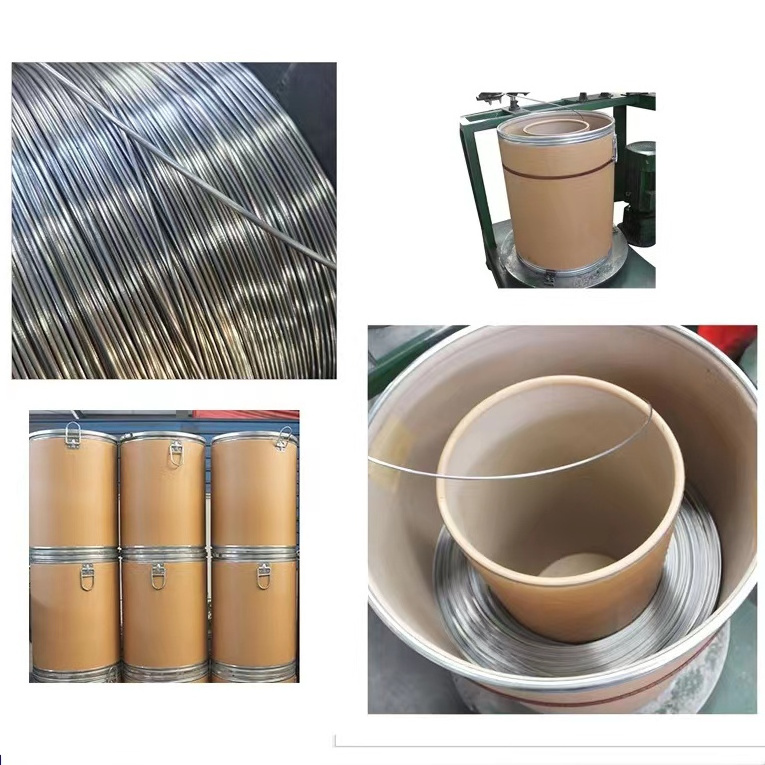

Package:

-

15kg per coil,250kg per barrel

-

Delivery Time:

-

Usually 7-10 days

Quick Details

-

Material:

-

Carbon steel, alloy

-

Diameter:

-

1.2-2.8mm(Custom)

-

Melting Point:

-

800-1400℃

-

Weight:

-

Normally 15KG or 250kg

-

Flux Content:

-

None(custom)

-

Place of Origin:

-

Shanxi, China

-

Brand Name:

-

ODM OEM

-

Model Number:

-

VTD101W-O, VTD101W-O

-

Application:

-

Cement, Metallurgical, Power, Mining , etc

-

Type/Keyword:

-

Welding wire

-

Alloy Or Not:

-

Is Alloy

-

Tolerance:

-

±1%

-

Processing Service:

-

Welding, Cutting

-

Chemical Composition:

-

C: 2.5-5.0 Cr: 22.5-27.5

-

Hardness:

-

58 - 62 HRC

-

Performance:

-

no slag, low spatter, high welding efficiency

-

Package:

-

15kg per coil,250kg per barrel

-

Delivery Time:

-

Usually 7-10 days

Products Description

|

Product Name

|

Flux cored welding wire

|

|

Warranty

|

3 years

|

|

Customized support

|

OEM, ODM

|

|

Place of Origin

|

Jiangsu province, China

|

|

Operating Temperature

|

Standard Temperature

|

|

Application

|

Structural Steel

|

|

In Stock

|

Spot Sales

|

|

Supply Capacity

|

Monthly production of 300 tons of wear-resistant welding wires

200 pieces of wear-resistant plates of various specifications monthly 200 tons of wear-resistant welding parts monthly |

Other product & h

istorical c

ustomized product styles

Whether your company chooses a product from the predetermined catalog or seeks assistance

in engineering applications, please feel free to contact our customer service center at any time and inform us of your procurement

requirements.

HFC hardfacing surfacing repair and remanufacturing services

Our factory is the leading domestic manufacturer of HFC hardfacing remanufacturing technology, forming a comprehensive anti-wear technology including complete surfacing materials, welding special equipment, welding machines and wear-resistant surfacing remanufacturing services.

Main product size

|

Grade

|

Standard

|

Chemical Composition of Deposited Metal

|

Mechanical Properties of Deposited Metal

|

Applicaton

|

|

VTE711

|

GB/T10045 E501T-1

AWS A5.20 E71T-1C |

C:0.05% Mn : 1.38% Si:0.45%

A5:0.008% P:0.012% |

C:0.05% Mn : 1.38%

Si:0.45% A5 :0.008% P:0.012% |

Suitable for the welding of shipbuilding steel structures,bridges,etc

|

|

VTD101Mo-0

|

Enterprise Standard

|

C 、Mn、i 、 Cr 、Mo 、 B

|

Hardness HRC>60 (as welded)

|

Suitable for overlay welding repair of squeeze rolls, vertical grinding rolls. grinding discs of roller presses, etc.

|

|

VTD103-0

|

Enterprise Standard

|

C 、Mn 、Si 、Cr 、Mo 、Nb

|

Hardness HRC>62 (as welded)

|

Suitable for overlay welding repair of squeeze rolls, vertical grinding rolls, grinding discs of roller presses, etc.

|

|

VTD101W-O

|

Enterprise Standard

|

C 、Mn 、Si 、Cr 、Mo 、W 、B

|

Hardness HRC>62 (as welded)

|

Suitable for surfacing repair of sieve plate, chute, hot dust transfer pipe, bucket, liner, etc.

|

|

VTD260-0

|

Enterprise Standard

|

C 、Mn 、Si 、Cr

|

Hardness HRC>58 (as welded)

|

Suitable for surfacing repair of sieve plate, chute, hot dust transfer pipe, bucket, liner, etc.

|

Application industry of the product

|

Industry

|

Application Scenario

|

Our important customers

|

|

Cement Industry

|

Mainly used in powder separator blades, impact disks, pipes, pump casings, mill linings, crusher parts, slag discharge tanks,

various chassis, vibrating screens, etc. |

Citic Heavy Industries Co.,Ltd., Tianjin Cement Industry Design and Research Institute Co., Hefei Cement Research and Design

Institute Co., Ltd, Loesche GmbH, Ube, Flsmidth & Co (FLS), Chengdu Leejun Industrial CO.,LTD. |

|

Matellurgical Idustry

|

Mainly used in silo liners, carts, hoses, distributors and bases, hoppers, weighing hoppers, pipes, pump casings, crusher

components, slag discharge tanks, fan casings, fan blades, vibrating screens, etc. |

Taiyuan Stainless Steel Co., Ltd., Shandong Rizhao Iron and Steel Co., Ltd., Shanxi Liheng Iron and Steel Co., Ltd., and other

large iron and steel enterprises. |

|

Mining Industry

|

Mainly used in coal washing and mining and mineral transportation, truck container linings, silo linings,scraper conveyor middle

and bottom plates, linings of conveying tanks, coal preparation plants, vibratingscreens.etc |

Sany Heavy Industry

|

|

Power-generation Industry

|

Mainly used in ash outlets, silos, fan blades, burner pipelines, linings of hoppers and hoppers, crusher parts, coal mill import

and export parts, air handling systems and conveyors. |

State Power Investment Corporation, China Datang Power Group, China Huaneng Group and other major thermal power projects.

|

|

Other Industry

|

Construction machinery, glass, papermaking, sand making, channel dredging, brick and tile machinery, coking industry, agricultural

machinery, ports and docks. |

etc.

|

Notice:

1) The flow rate of shield gas should within 20L-25L/min in welding.

2) The wire extention should be 15mm-25mm.

3) The surfaces to be welded must be cleaned away impurities of oil contamination, rust, moisture and so on.

4) The welding conditions mentioned above for reference only and it is better to do a welding procedure qualifcation according to project before put it into formal welding.

Hot Searches