- Product Details

- {{item.text}}

Quick Details

-

Dimension(L*W*H):

-

3000x1620x1100mm

-

Weight:

-

1t

-

Local Service Location:

-

Bangladesh, Kazakhstan, Nigeria

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service

-

Product name:

-

High Efficiency Mining Equipment Density Small Gold Shaking Table

-

After sale service:

-

Life-long Service

-

Installation:

-

Under Guidance

-

Color:

-

Customized

-

Application:

-

Gold, Chrome, Manganess, etc.

-

Stroke:

-

10-30mm

-

Water Added:

-

0.3-1.5 tph

-

Recovery Rate:

-

98 %

-

Spare parts:

-

Life-long Time

-

Production Capacity:

-

above 98%

-

Certification:

-

ce

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

Hongji

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3000x1620x1100mm

-

Weight:

-

1t

-

Local Service Location:

-

Bangladesh, Kazakhstan, Nigeria

-

After-sales Service Provided:

-

Video technical support, Free spare parts, Online support, Field installation, commissioning and training, Field maintenance and repair service

-

Product name:

-

High Efficiency Mining Equipment Density Small Gold Shaking Table

-

After sale service:

-

Life-long Service

-

Installation:

-

Under Guidance

-

Color:

-

Customized

-

Application:

-

Gold, Chrome, Manganess, etc.

-

Stroke:

-

10-30mm

-

Water Added:

-

0.3-1.5 tph

-

Recovery Rate:

-

98 %

-

Spare parts:

-

Life-long Time

-

Production Capacity:

-

above 98%

-

Certification:

-

ce

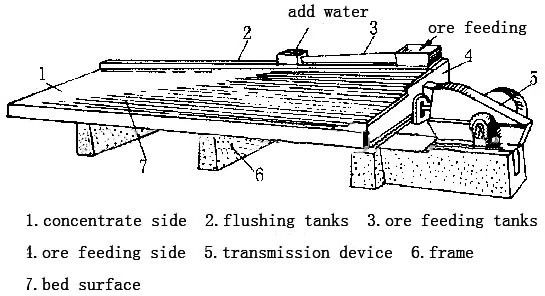

Product Introduction

The shaking table is a gravity dressing machine used for separating fine particles. They are mainly used for various metals such as gold, silver, zinc, tungsten, iron, manganese, lead and coal and heavy metal materials. It is suitable for different grades of materials such as 2-0.5mm, coarse sand of 0.5-0.074mm, fine sand, and slime of 0.074mm. When the beneficiation shaker processes tungsten or tin metal ore materials, the effective recovery range of the equipment is 2-0.22 mm.

Shaking Table Features:

1. High concentrating ratio, high beneficiation efficiency.

2. Simple operation. It can realize the final concentrating and final tailing only for once.

3. Compared with traditional technology, without reagent.

4. Low energy consumption; high performance.

working principle

Working principle of mineral separating shaking table

1.Mineral separating shaking table is Joint action of an inclined surface of bed with the aid of mechanical flagstone symmetrical reciprocal motion and thin layer incline current of water and so on.

2.It makes the ore grain on the surface of bed the loose lamination, thus enables the mineral separation according to the density different.

Technical parameters of shaking table

|

Name |

Unit |

Grit concentrator table |

Fine sand concentrator table |

Sludge concentrator table |

|

|

Dimensions |

Length |

MM |

4450 |

4450 |

4450 |

|

Driving part width |

MM |

1855 |

1855 |

1855 |

|

|

Concentrate part width |

MM |

1546 |

1546 |

1546 |

|

|

Max.feeding size |

MM |

2 |

0.5 |

0.15 |

|

|

Feeding amount |

T/d |

30-60 |

10-20 |

15-25 |

|

|

Feeding thickness |

% |

25-30 |

20-25 |

15-25 |

|

|

Journey |

MM |

16-22 |

11-16 |

8-16 |

|

|

Frequency |

F |

15-48 |

48-53 |

50-57 |

|

|

Water quantity |

T/d |

80-150 |

30-60 |

10-17 |

|

|

Horizontal obliquity |

Degree |

2.5-4.5 |

1.5-3.5 |

1-2 |

|

|

Portrait obliquity |

% |

1.4 |

0.92 |

---- |

|

|

Table board corner |

Degree |

32-42 |

40 |

42 |

|

|

Concentrating square |

---- |

7.6 |

7.6 |

7.6 |

|

|

Table board length ratio |

---- |

2.6 |

2.6 |

2.6 |

|

|

Motor power |

KW |

1.1 |

1.1 |

1.1 |

|

Customer Case

Packing And Delivery