- Product Details

- {{item.text}}

Quick Details

-

Oiled or Non-oiled:

-

Customized

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HYT

-

Outer Diameter:

-

20 - 200 mm

-

Thickness:

-

1 mm ~ 60 mm

-

Technique:

-

ERW,SAW,EFW

-

Grade:

-

A106 A53 A333 A519 A500 A335 A513

-

Product name:

-

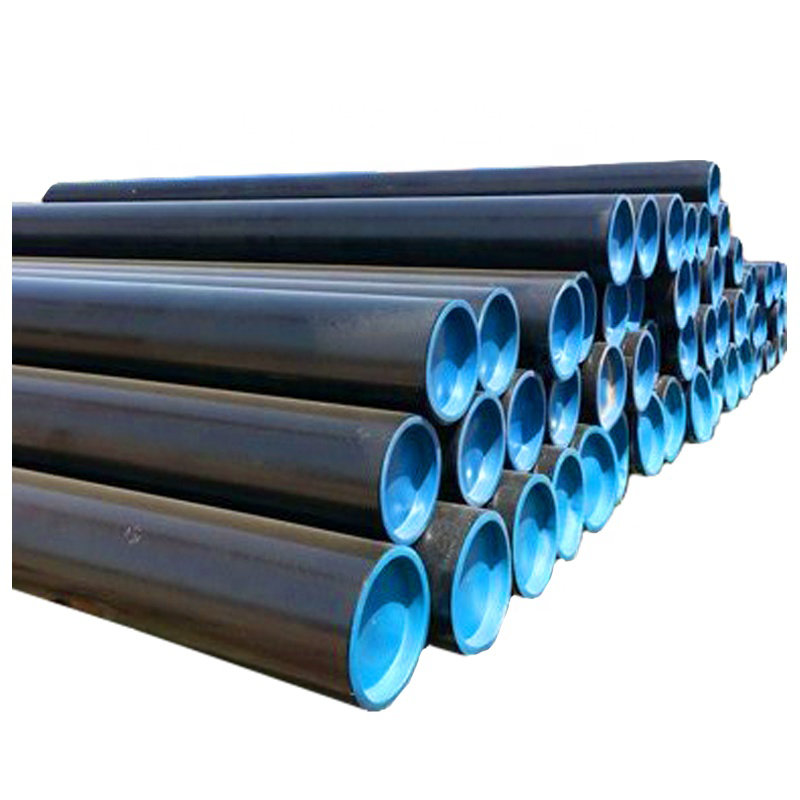

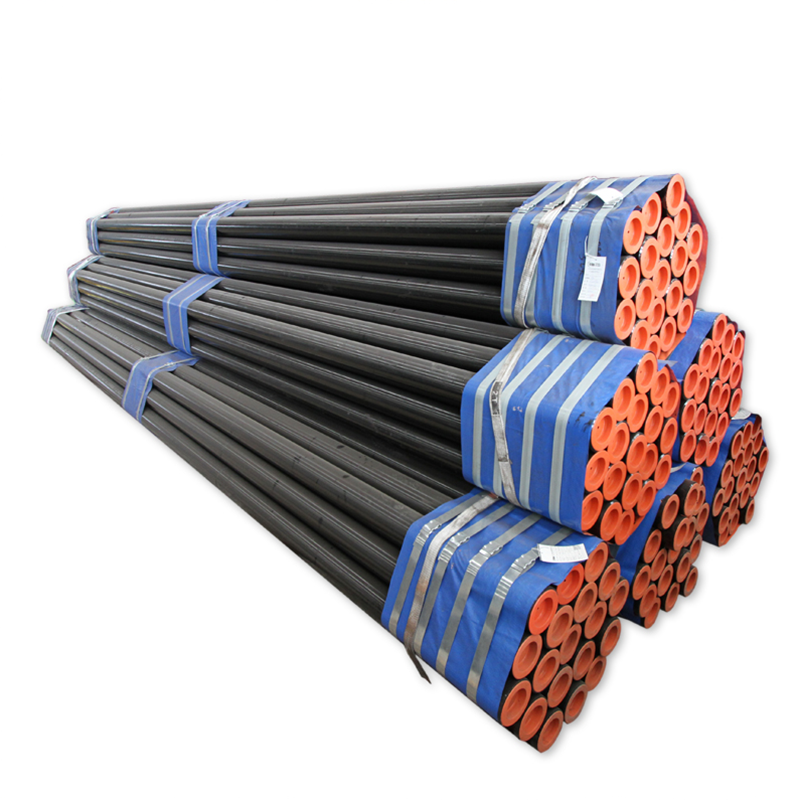

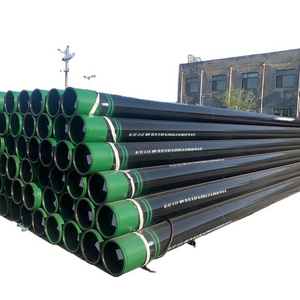

carbon welded Steel Tube

-

Surface:

-

Black Painted, galvanized coating

-

Shape:

-

Round Pipe Tube

-

Type:

-

Welded Steel Pipe

-

Material:

-

Q235/Q235B/Q345/Q345B/A106/A53

-

Keyword:

-

carbon Steel Pipe

-

Usage:

-

Oil Gas Sewage Transport/building

-

MOQ:

-

1 Ton

-

Packing:

-

Standard Seaworthy Packing

Quick Details

-

Section Shape:

-

Round

-

Surface Treatment:

-

Hot Rolled

-

Tolerance:

-

±1%

-

Oiled or Non-oiled:

-

Customized

-

Invoicing:

-

by actual weight

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

HYT

-

Outer Diameter:

-

20 - 200 mm

-

Thickness:

-

1 mm ~ 60 mm

-

Technique:

-

ERW,SAW,EFW

-

Grade:

-

A106 A53 A333 A519 A500 A335 A513

-

Product name:

-

carbon welded Steel Tube

-

Surface:

-

Black Painted, galvanized coating

-

Shape:

-

Round Pipe Tube

-

Type:

-

Welded Steel Pipe

-

Material:

-

Q235/Q235B/Q345/Q345B/A106/A53

-

Keyword:

-

carbon Steel Pipe

-

Usage:

-

Oil Gas Sewage Transport/building

-

MOQ:

-

1 Ton

-

Packing:

-

Standard Seaworthy Packing

Product Specification

ASTM A53 Carbon Steel Pipe Specification and Dimension

Jiangsu HYT stocks seamless and welded ASTM A53 pipe in a broad range of sizes and dimensions to meet your needs. Our inventory

includes:

Types: Seamless, Welded (ERW), Galvanized

Sizes: 1/2” NPS to 26” OD

Schedules: S/10, S/20, S/40, STD, S/60, S/80, XH, S/100, S/120, S/140, S/160 and XXH

Length: 20 ft, 40 ft, customized

Ends: Plain, Beveled, Threaded

Coating: 3PE, FBE, Varnished, Black, Zinc Coated

Scope of ASTM A53

ASTM A53 and ASME SA53 is intended for mechanical and pressure applications and is also acceptable for ordinary uses in steam,water, gas and air lines. It is suitable for welding and for forming operations involving coiling, bending, and flanging, subject to certain qualifications.

A53 covers Seamless and Welded, Black and Hot-Dipped Galvanized nominal (average) wall pipe for coiling, bending, flanging and other special purposes and is suitable for welding. Continuous-Welded pipe is not intended for flanging. Purpose for which pipe is intended should be stated on order.

Materials and Manufacture of ASTM A53

The steel for both seamless and welded pipe shall be made by one or more of the following processes: open-hearth, electric furnace, or basic-oxygen. The weld seam of electric-resistance welded pipe in Grade B shall be heat treated after welding.

Application of ASTM A53

Piping Systems

: Steel pipes specified under the ASTM A53 standard are suitable for various piping systems, including pipelines for transporting steam, water, gas, and air.

Structural and Mechanical Applications

: These pipes are suitable for special purposes requiring bending, coiling, flanging, and welding, and are suitable for welding.

General Industrial Usage

: Due to their good weldability and bendability, ASTM A53 steel pipes are widely used for general industrial purposes.

Pressure and Mechanical Applications

: Steel pipes under the ASTM A53 specification are also suitable for applications involving pressure and mechanical uses.

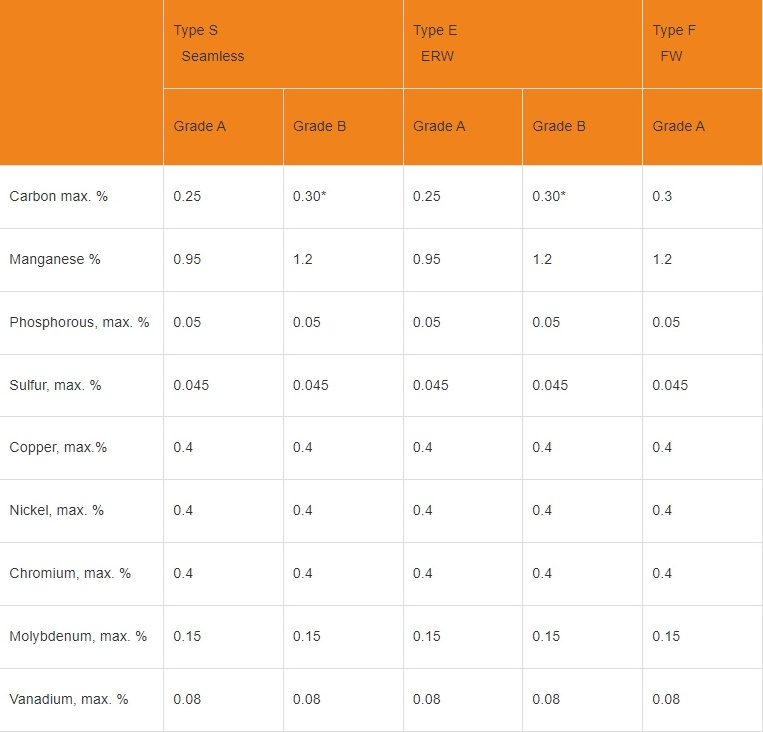

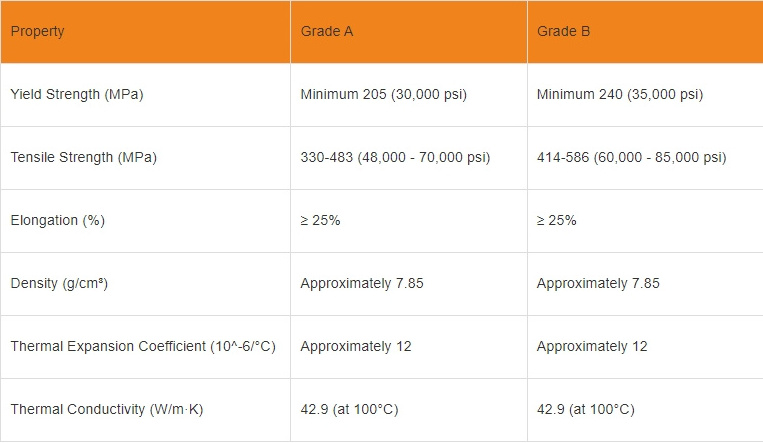

Chemical Composition of ASTM A53

Physical Property and Mechanical Property of ASTM A53

Benefits of ASTM A53

Wide Range of Applications

: Due to its high-temperature resistance, it's frequently used in refineries, power plants, boilers,

shipbuilding, heat exchangers, and other applications requiring high temperatures and pressures.

Corrosion Resistance

: The steel pipe can be galvanized, enhancing its antioxidation and corrosion resistance.

Weldability

: A53 steel pipes are suitable for welding, bending, and flanging, offering versatility during connections and

installations.

High Mechanical Strength

: Particularly A53 Grade B, provides good yield strength and tensile strength, suitable for use in various

environments.

Standardization

: The ASTM A53 specification ensures all pipes supplied by manufacturers are consistent in dimensions, material,

and mechanical properties.

Stringent Quality Testing

: According to ASTM A53 requirements, all pipes must undergo hydrostatic testing, non-destructive

electric tests, etc., to ensure their quality and performance.

Variety

: A53 carbon steel pipes are available in multiple types and grades depending on their manufacturing process and

application needs, such as electric resistance welded, seamless, and furnace-butt welded.

Cost-Effective

: Due to its widespread use and production, A53 carbon steel pipe often provides cost benefits, offering reasonable

prices while still maintaining high quality and performance.

Longevity

: When correctly installed and maintained, ASTM A53 carbon steel pipes can offer long-term reliability and performance.

Environmentally Friendly

: Carbon steel is recyclable, meaning that it can be melted down and used to manufacture new steel

products once its life cycle ends, reducing waste.

Our Supply Range for ASTM A53 Pipe

Jiangsu HYT stocks seamless and welded ASTM A53 pipe in a broad range of sizes and dimensions to meet your needs. Our inventory

includes:

Types: Seamless, Welded (ERW), Galvanized

Sizes: 1/2” NPS to 26” OD

Schedules: S/10, S/20, S/40, STD, S/60, S/80, XH, S/100, S/120, S/140, S/160 and XXH

Length: 20 ft, 40 ft, customized

Ends: Plain, Beveled, Threaded

Coating: 3PE, FBE, Varnished, Black, Zinc Coated

Other Product Details

|

Brand

|

HYT

|

|

|

|

|||

|

Origin

|

China

|

|

|

|

|||

|

Application Industry

|

Oil and Gas, Construction, Water Supply and Treatment, Automotive, Power Generation, etc.

|

|

|

|

|||

|

Surface Treatment

|

Acid pickling, Wire drawing, Polishing, Sandblasting, Shot blasting, Electrochemical polishing, Titanium plating, PVD (Physical Vapor Deposition), Chemical coloring, Heat treatment, Annealing.

|

|

|

|

|||

|

Surface Finish

|

NO.1, 2D, 2B, BA (Bright Annealed), NO.3, NO.4, HL (Hair Line), NO.7, NO.8, SATIN.

|

|

|

|

|||

|

Color

|

Silver (Natural Steel), Black (Coated or Oxidized), Galvanized (Zinc), Green (Coated), Blue (Coated), Red (Coated), Yellow (Coated), White (Coated).

|

|

|

|

|||

|

Pipe Ends

|

Plain End (PE), Beveled End (BE), Threaded End (TE), Grooved, Bell End, Tapered, Expanded.

|

|

|

|

|||

|

Tolerance

|

As standards’ Requirements

|

|

|

|

|||

|

Test

|

Support Third-party Test.

|

|

|

|

|||

|

Certification

|

GB/T19001-2016/ISO9001:2015

GB/T24001-2016/ISO14001:2015 GB/T 45001-2020/ISO 45001:2018 |

|

|

|

|||

|

Processing Service

|

Cutting, Bending, Threading, Welding, Grooving, Coating, Drilling, Galvanizing, Heat Treatment, Punching.

|

|

|

|

|||

|

Sample

|

Free Sample Available

|

|

|

|

|||

|

Stock Status

|

Continuous Supply Of Spot Products

|

|

|

|

|||

|

MOQ

|

1 Ton

|

|

|

|

|||

|

Packaging

|

Bundled, Wooden Cases, Plastic Wrapping, Plastic Caps, Palletized, Shrink Wrapped, Plastic Bagged, Steel Crates, Loose, Boxed.

|

|

|

|

|||

|

Port

|

Shanghai

|

|

|

|

|||

|

Delivery Term

|

EXW, FOB, FCA, etc.

|

|

|

|

|||

|

Delivery Time

|

3-5 days for the regular models, and 7 to 10 working days for the special sizes and processing

|

|

|

|

|||

|

Payment Term

|

T/T, L/C, D/P, etc.

|

|

|

|

|||

|

Customization

|

Customization Available

|

|

|

|

|||

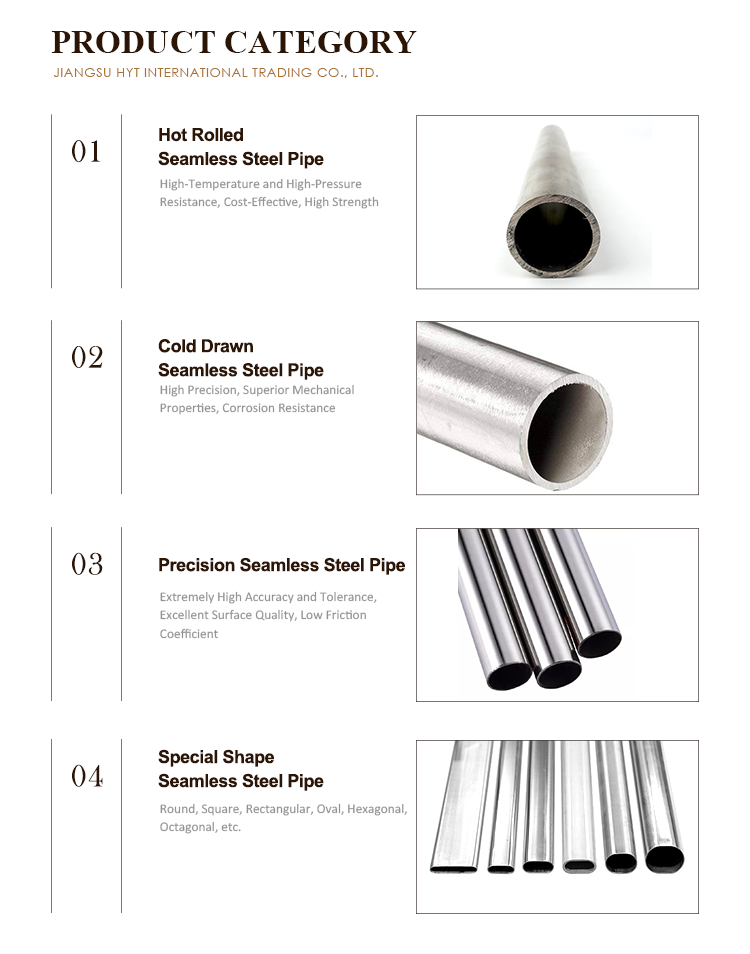

Product Category

Product Application

Wide Application Range Help You Overcome Tough Projects

Our metal products are widely used in industrial electric furnaces, civil nuclear power, power station boilers, petrochemical

industry, aerospace, ships, automobiles, machinery, communication electronics, instruments for the application of high resistance, high temperature, corrosion resistance, heat resistance, wear resistance, fatigue, creep and other use environment. We provide customers with scientific solutions and excellent product service from the material perspective.

Hot Searches