- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

KS

-

Name:

-

Concrete Stamp Mold

-

Advantage:

-

Flexibility

-

Thickness:

-

20-25mm

-

Features:

-

Durable

-

Application:

-

Driveway, Pool Deck, Patio, Walkway Or Walls.

-

Appearance:

-

Aged Cobblestones, Brickwork, Flagstones

-

Color:

-

Red ,Blue,Yellow,Brown, Black

-

Warranty:

-

5 years

-

Mould Life:

-

20000 Times

-

Delivery Time:

-

Within 3 Days

Quick Details

-

Shaping Mode:

-

Silicone Mould

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

KJ

-

Model Number:

-

KS

-

Name:

-

Concrete Stamp Mold

-

Advantage:

-

Flexibility

-

Thickness:

-

20-25mm

-

Features:

-

Durable

-

Application:

-

Driveway, Pool Deck, Patio, Walkway Or Walls.

-

Appearance:

-

Aged Cobblestones, Brickwork, Flagstones

-

Color:

-

Red ,Blue,Yellow,Brown, Black

-

Warranty:

-

5 years

-

Mould Life:

-

20000 Times

-

Delivery Time:

-

Within 3 Days

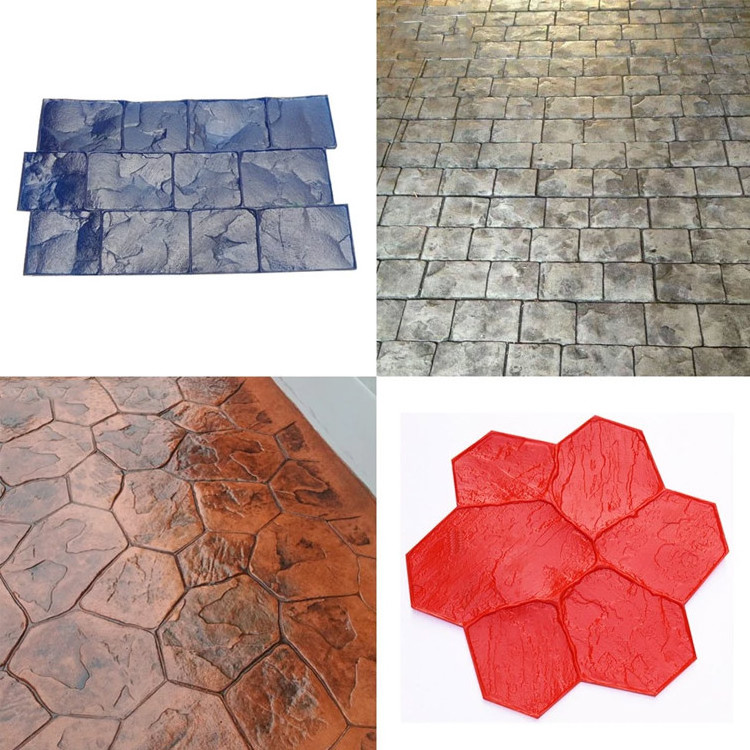

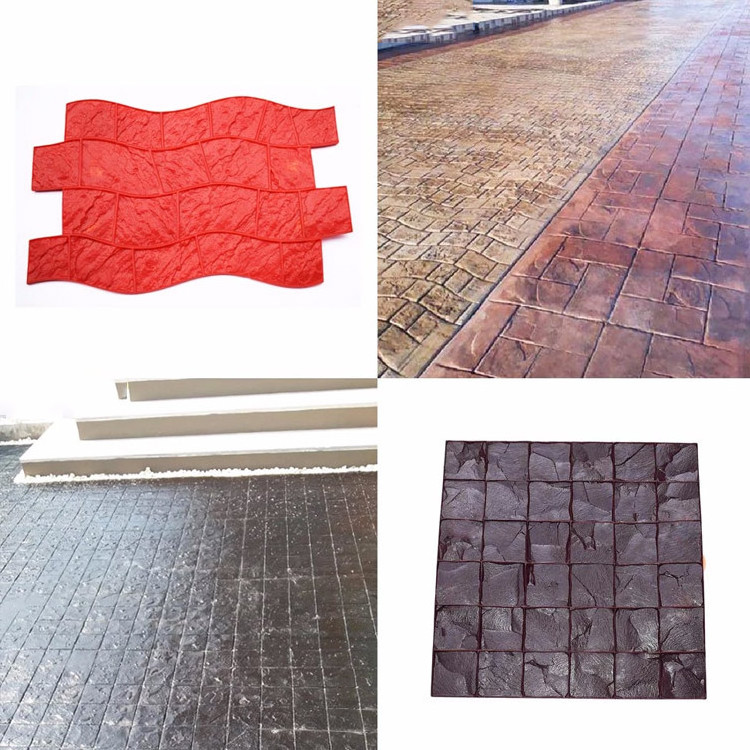

Product display

We have more than

1000 designs.

You can find all the designs you want here.

we have series of color hardener,release agent,liquid sealer,bull float and hand trowels.One-stop shopping to solve your concrete stamping problems!

Product details

Flooring set is the process of pressing decorative or natural impressions into wet concrete using rubber stamps. This is a great way to add a unique flair to your driveway, pool deck, patio, walkway or walls.

There are many benefits to using stamped concrete. Concrete is one of the most durable building materials available for paving, which comes in handy in high traffic areas such as driveways and walkways.

Choosing stamped concrete over other paving materials such as natural stone can be a more economical choice. Done right, stamped concrete can look just as high quality as these other methods. For instance, a stamped concrete job can be installed in a portion of the time as natural materials takes, which allows< contractors to be more productive.

The biggest advantage to stamped concrete is the flexibility. Concrete stamping, combined with different finishing techniques,allows for unlimited design opportunities such as aged cobblestones, brickwork, flagstones, slate tile, marble, granite, wood, or just about any natural surface.

|

Polyurethane

|

Polyurethane

|

|

|

||

|

Color

|

Red, Yellow, Blue, Orange, Green, Customization According To Customer Requirements

|

|

|

||

|

Usage

|

Ground Pressure

|

|

|

||

|

Warranty

|

5 Years

|

|

|

||

|

Pattern

|

Rock, Cobblestone, Wooden, Ashler

|

|

|

||

|

Thickness

|

20-25mm

|

|

|

||

|

Size & Weight

|

Different Designs With Different Size And Weight

|

|

|

||

Why choose us

1.Our strengths

Repeated use

3.

Diverse styles

Our three quality commitments

Usage method

Step 1: Making the wet cement floor to even, no water hole on the surface.

Step 2: Casting color hardener on the cement floor, normally 3-4kg on 1 square meter.

Step 3: when the color hardener is humid, making the floor smooth with bull float.

Step 4: Casting release agent on the floor, normally 0.15kg on 1 square meter.

Step 5: Stamping the floor with concrete stamp mat and Plate Temper.

Step 6: Hold 3days for curing, then spray sealer on the floor, 0.2kg on 1 square mater.

Authentication

About us

FAQ

Q1: How about the quality?

A1. Quality is guaranteed, Henan Kejie Industrial Co, Ltd has more than 10 years industrial experience

Q2: If the price is solid?

A2: The price is negotialbe, it could change according to your order quantity

Q3: Can I have the sample for free?

A3. We can send a small piece to you for free, but need you to handle the freight cost.

Q4: How about the payment terms?

A4: The prefer payment terms is 30% TT against order, and balance before shipping

Hot Searches