- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Tinwing, Tinwing

-

Dimension(L*W*H):

-

Customized

-

Capacity:

-

Customized

-

Weight:

-

100000

-

Inner Material:

-

Stainless steel/ carbon steel

-

Outer Material:

-

Stainless steel/ carbon steel

-

Design Pressure(MPa):

-

4

-

Design Standard:

-

ASME/PED/GB

-

Working Temperature(℃):

-

100 - 500 ℃

-

Control System:

-

Automatic Control

-

Working pressure:

-

Customer's need

-

Applications:

-

space vehicle/ carbon fiber/glass fiber

-

Color:

-

Customized

-

Product name:

-

Autoclave

-

Door seal type:

-

Inflatable silicone seal ring

-

Cooling way:

-

Water

-

Heating Method:

-

Tube heating

Quick Details

-

Volume (m³):

-

10

-

Max Working Pressure(MPa):

-

3.8 MPa

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tinwing, Tinwing

-

Dimension(L*W*H):

-

Customized

-

Capacity:

-

Customized

-

Weight:

-

100000

-

Inner Material:

-

Stainless steel/ carbon steel

-

Outer Material:

-

Stainless steel/ carbon steel

-

Design Pressure(MPa):

-

4

-

Design Standard:

-

ASME/PED/GB

-

Working Temperature(℃):

-

100 - 500 ℃

-

Control System:

-

Automatic Control

-

Working pressure:

-

Customer's need

-

Applications:

-

space vehicle/ carbon fiber/glass fiber

-

Color:

-

Customized

-

Product name:

-

Autoclave

-

Door seal type:

-

Inflatable silicone seal ring

-

Cooling way:

-

Water

-

Heating Method:

-

Tube heating

Product Introduction

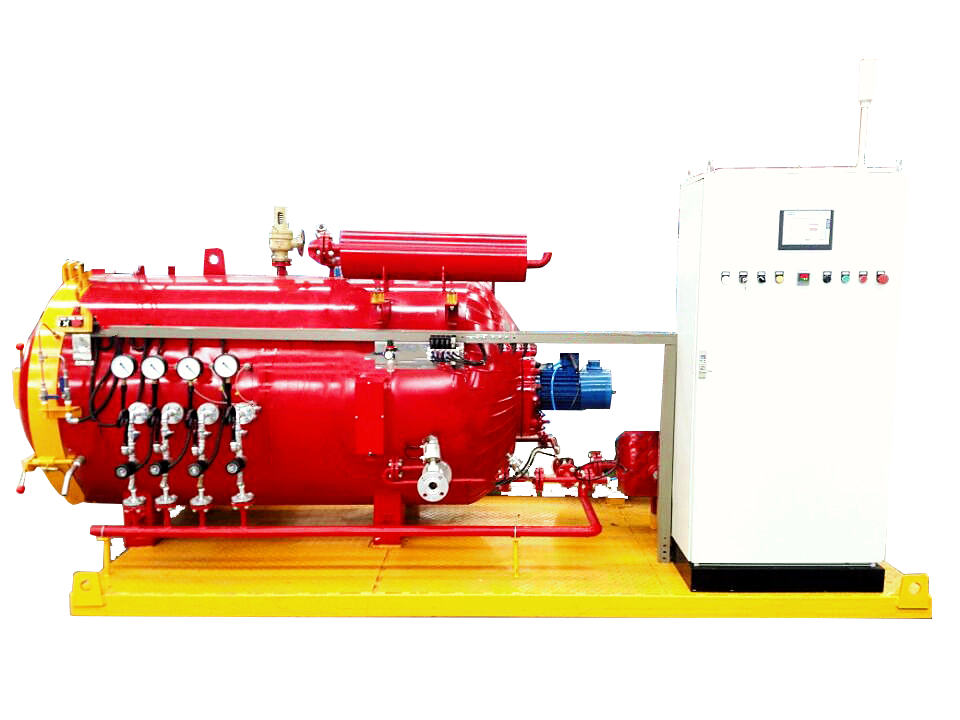

High Pressure High Efficiency Composite Autoclave Pressure Vessels for Glass Fiber Carbon Fiber Composite Materials

The composite material autoclave mainly used to the composite materials military products,space vehicle by high temperature and high pressure.It also can be applied to strengthen the carbon fiber,glass fiber,boron fiber and ect.More over,it also can change the metallic/nonmetallic joint components,such as airplane door,fairing,airborne radar and so on.

|

Project

|

|

Use parameters

|

|

|

Name

|

|

Carbon Fiber Composite autoclave

|

|

|

Size

|

Container specifications

|

Φ1100m×2500m

|

|

|

Pressure

|

Maximum working pressure

|

1.0MPa

|

|

|

|

Boost rate

|

0.1-0.5MPa/min Adjustable

|

|

|

|

Reduction rate

|

0.1-0.5MPa/min Adjustable

|

|

|

|

Pressure Control Precision

|

0.001MPa

|

|

|

Temperature

|

Maximum operating temperature

|

250℃

|

|

|

|

Heating rate(no load)

|

0.1-3℃

|

|

|

|

Temperature control accuracy (display)

|

0.1℃

|

|

|

|

Temperature field uniformity

|

±3℃

|

|

|

Vacuum

|

Vacuum

|

-0.098MPa

|

|

|

|

Vacuum piping

|

6 way +6 way standby

|

|

System Composition

Autoclave can realize temperature ,pressure ,cooling and process parameters timing ,real-time on line controlled equipment .Mainly device into below systems:

1.

tightness of tank

:it is made from tank ,tank door ,high temperature motor ,air duct heat partition layer to form into one high pressure resistant ,high temperature tank

2.

safety interlock

: it is made from pressure automatic interlock ,manual interlock ,over pressure alarm device.

3.

Quickly open door device

:manual or automatic quickly open design ,even If power off ,it can start and close the door

4.

Sealing device

: the door adopt silica gel filling air ,it can bear 500 degree ,forming into one high temperature high pressure sealed container

5.

Pressure system

: pressure transfer and control system include air compressor ,storage tank ,pressure control valve ,pipe ,pressure transformer ,and pressure gauge .

6.

Heating system:

stainless steel heating pipe ,high temperature fan ,wind plate ,insulation layer ,temperature control system .heating power satisfy with inside tank max temperature requirement and raising temperature

7.

Temperature circulation system

:it made up of circulation fan ,wind plate ,and guide flow cover to improve heating transfer and circulation form into uniform temperature

8.

Vacuum system

:it made up of vacuum pump ,pipe ,vacuum gauge ,vacuum vale ,to supply composite material vacuum condition

9.

Automatic control system

:adopt PLD and fuzzy control ,to realize the pressure ,temperature ,cooling and so on full process high –precision control and in time record

Product Overview

①Adopt

Siemens automatic control system

,save energy and manpower

②Uniform heat distribution in the tank,

constant pressure.

③Suitable for curing of

various kinds of composite materials.

④Perfect pressure control,forming effect is good.

⑤The hot pressure tank adopts

PLC automatic control system

,with accuracy up to ±1-2℃.

⑥Thermal insulation tank with aluminum silicate wool,head with double layer insulation,plus stainless steel lining insulation effect is good.

⑦With quick opening type pressure vessel double safety interlock device.Synchronous alarm,pressure boost after closing,pressure relief after opening.

Packaging & Delivery

Before delivery, our professional engineer will do trial run for each machine to check and confirm everything is workable, you also can come to our factory for testing together with us.when loading, our workers will fix the machine tightly in the container to ensure the safety in the transportation.

Application

Widely used in aircraft, missiles, satellites and space shuttle, such as the airplane cabin door, fairing, airborne radar cover, the plane bracket, empennage.

Composite material processing. Carbon fiber, boron fiber, aramid fiber, glass fiber, metal composites, reinforced plastics and etc..

Hot Searches