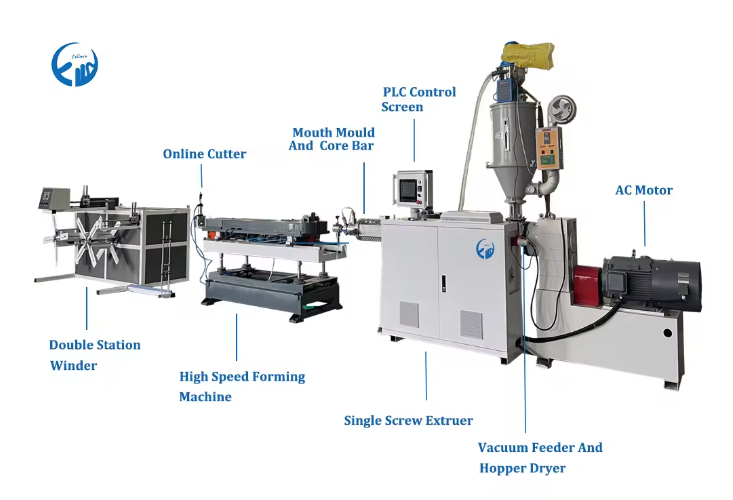

1. Vacuum Hopper material: stainless steel

2. Work mode: required raw materials to the hopper by means of vacuum suction.

3.

The base of the feeding machine adopts a water jacket water cooling system.

Its material is Q235-A.