- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V

-

Weight:

-

300 KG

-

Dimension(L*W*H):

-

5*2.1*2.5m

-

Raw Material:

-

Sawdust

-

Finished Products:

-

Shisha Charcoal Tablets

-

Name:

-

Bio Briquette Machine

-

Suitable material:

-

Hard Wood Briquette

-

Function:

-

Press Biomass Material

Quick Details

-

Warranty:

-

1 Year

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

runxiang

-

Voltage:

-

380V

-

Weight:

-

300 KG

-

Dimension(L*W*H):

-

5*2.1*2.5m

-

Raw Material:

-

Sawdust

-

Finished Products:

-

Shisha Charcoal Tablets

-

Name:

-

Bio Briquette Machine

-

Suitable material:

-

Hard Wood Briquette

-

Function:

-

Press Biomass Material

Product Description

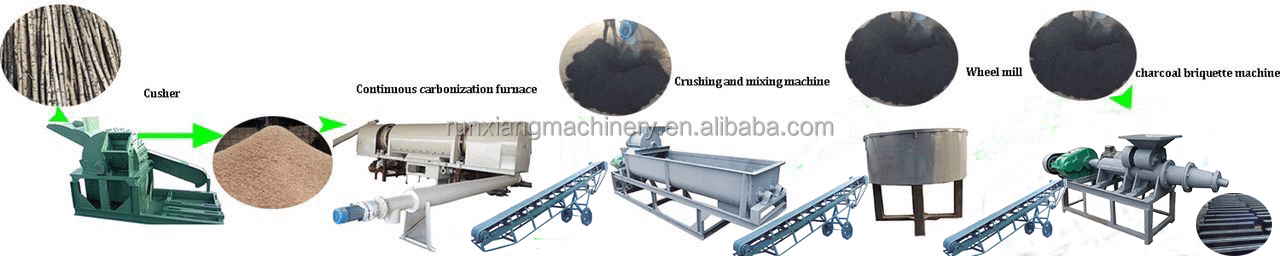

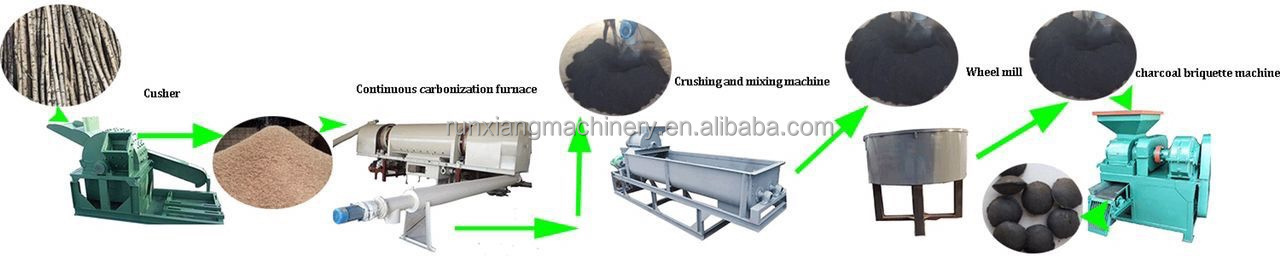

This is a charcoal processing machine. The raw materials can be various biomass wastes, such as coconut husk, rice husk, and peanut husk. With these raw materials, these wastes can be converted into treasures, which can be used for cooking, industrial fuels, and so on. It includes a carbonization furnace, a pulverizing and mixing machine, a wheel mill, and a coal rod extruder.

-

-Horizontal Environmental Protection Carbonization Furnace

The new environmentally friendly carbonization furnace adds a flue gas recovery device to the original carbonization furnace.

After the flue gas is recovered, it can be dust-free and smoke-free. The recovered flue gas can be ignited like liquefied gas and can be used by a dryer.

At present, there are three types of carbonization furnaces, common type (can only be used to produce charcoal, not to collect gas); wood carbonization equipment (used to carbonize branches, wood blocks, coconut shell blocks, scrap pieces in furniture factories, etc. The equipment can be configured The gas recovered by the gasification furnace device can be turned into fuel gas for the carbonization furnace's own use or other); the new environmentally friendly carbonization furnace has the function of one machine and two purposes, and the materials can also be directly carbonized, or can be carbonized after making rods.

The new environmentally friendly carbonization furnace adds a flue gas recovery device to the original carbonization furnace.

After the flue gas is recovered, it can be dust-free and smoke-free. The recovered flue gas can be ignited like liquefied gas and can be used by a dryer.

At present, there are three types of carbonization furnaces, common type (can only be used to produce charcoal, not to collect gas); wood carbonization equipment (used to carbonize branches, wood blocks, coconut shell blocks, scrap pieces in furniture factories, etc. The equipment can be configured The gas recovered by the gasification furnace device can be turned into fuel gas for the carbonization furnace's own use or other); the new environmentally friendly carbonization furnace has the function of one machine and two purposes, and the materials can also be directly carbonized, or can be carbonized after making rods.

Technical data

|

Model

|

RXTH-04

|

RXTH-08

|

RXTH-14

|

|

weight

|

2.5t

|

4.5t

|

6t

|

|

size

|

3*1.7*2.1m

|

4.5*1.9*2.3m

|

5*2.1*2.5m

|

|

Carbonization time

|

12h

|

12h

|

12h

|

|

capacity

|

800-1000kg(8-10h)

|

1800-2000kg(8-10h)

|

2800-3000kg(8-10h)

|

|

Volume

|

4CBM

|

8CBM

|

14CBM

|

-

-Introduction for Charcoal Coal Crushing And Mixing Machine

The double axis mixer is rotated through two groups of screw shafts with spiral blade, and water is added to the powder material for spraying wet mixing transportation, so that powdery material can achieve controllable humidity. The equipment is mainly suitable for humidification and mixing of raw materials in the fertilizer industry, so that the materials are fully mixing and this machine have the function of conveying too.

The double axis mixer is rotated through two groups of screw shafts with spiral blade, and water is added to the powder material for spraying wet mixing transportation, so that powdery material can achieve controllable humidity. The equipment is mainly suitable for humidification and mixing of raw materials in the fertilizer industry, so that the materials are fully mixing and this machine have the function of conveying too.

-

-Introduction For Wheel Mill

The wheel mill can increase the density of the carbon powder, which is more conducive to the formation of coal rods.

The wheel mill can increase the density of the carbon powder, which is more conducive to the formation of coal rods.

When the quantity of raw material is poured into the mixing tank from the feed inlet, the raw material is atomized by the water with relative pressure, which is stirred by the mixing shaft of the qualitative length to form a uniform water containing core.The whole agitation is divided into three areas: atomization area, mixing area and discharge area.The agitator leaves have well wear resistance and long service life.

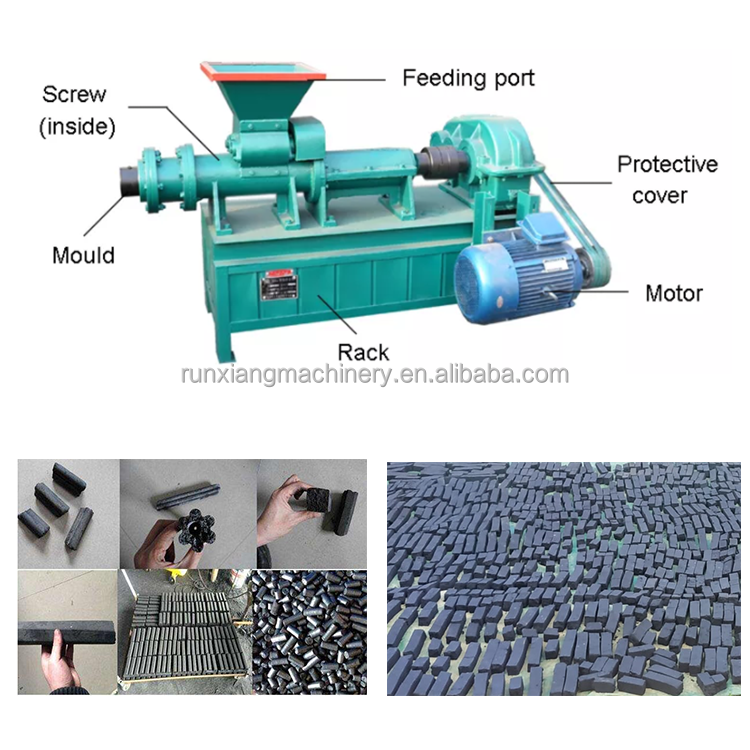

-Introduction For Charcoal Briquette Machine

Coal stick machine can produce various coal stick shapes, such as hexagon, circle, square, quadrilateral, etc.

Coal stick machine can produce various coal stick shapes, such as hexagon, circle, square, quadrilateral, etc.

Relate machine

Packing & Delivery

wooden case packing

Hot Searches