- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

2200

-

Product name:

-

Duplex Vacuum Plodder

-

Function:

-

Bar Soap Extrusion

-

Operating:

-

Automatic

Quick Details

-

Brand Name:

-

BritSoap

-

Type:

-

Automatic Soap Machinery

-

Marketing Type:

-

New Product

-

Weight (KG):

-

2200

-

Product name:

-

Duplex Vacuum Plodder

-

Function:

-

Bar Soap Extrusion

-

Operating:

-

Automatic

Products Description

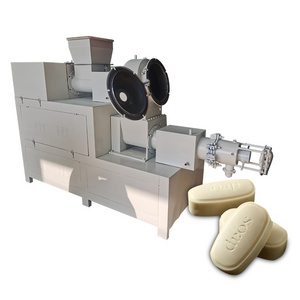

Duplex Vacuum Plodder

The Brit Soap Duplex Vacuum Plodder represents the most significant improvement in soap processing machinery in recent times. It combines an integrally mounted gearbox, driven by a motor on each barrel. The bottom barrel is equipped with a variable speed drive. It is impossible to overload the drive as it is completely protected by safety overloads on the electric panel.

The homogenized soap ribbons from the Triple Roll Mill are carried to the Duplex Plodder by means of a motorised elevating conveyor and dropped into the feed hopper into the top barrel of the duplex vacuum plodder.

The screw (worm) pulls the product into the compression zone and through the noodling plate. This refining action adds additional mixing, refining and filtering to the product before it enters the vacuum chamber.

The noodles fall under gravity into the screw of the bottom compression barrel. A strong vacuum is pulled within the chamber toensure all air is removed. This process ensures that the product is dense with no air pockets entrapped within.

The final compression barrel is fitted with a heated compression nose cone which is fitted with an extrusion plate with the

finished cross sectional shape of the final product. Each barrel is fitted with a water cooling jacket to aid extrusion and control the temperature of the product while be processed.

Brit Soap offers both Single Worm and Twin Worm Duplex Vacuum Plodders.

The homogenized soap ribbons from the Triple Roll Mill are carried to the Duplex Plodder by means of a motorised elevating conveyor and dropped into the feed hopper into the top barrel of the duplex vacuum plodder.

The screw (worm) pulls the product into the compression zone and through the noodling plate. This refining action adds additional mixing, refining and filtering to the product before it enters the vacuum chamber.

The noodles fall under gravity into the screw of the bottom compression barrel. A strong vacuum is pulled within the chamber toensure all air is removed. This process ensures that the product is dense with no air pockets entrapped within.

The final compression barrel is fitted with a heated compression nose cone which is fitted with an extrusion plate with the

finished cross sectional shape of the final product. Each barrel is fitted with a water cooling jacket to aid extrusion and control the temperature of the product while be processed.

Brit Soap offers both Single Worm and Twin Worm Duplex Vacuum Plodders.

Details Images

Product Specifications

|

Model

|

BSM / DVP 150

|

BSM / DVP 200

|

BSM / DVP 250

|

BSM / DVP 300

|

BSM / DVP 350

|

||||

|

Capacity of soap bar

|

200 kgs/hr

|

500 kgs/hr

|

1000 kgs/hr

|

2000 kgs/hr

|

2500 – 3000 kgs/hr

|

||||

|

Motor (Top + Bottom + Vacuum Pump + Nose Cone Heater)

|

5.5 kw + 5.5 kw + 1.5kw + 1 kw

|

7.5kw + 11 kw + 1.5kw + 1 kw

|

15kw + 15kw + 2.2 kw + 1 kw

|

22kw + 22kw + 3.7kw + 1kw

|

30kw + 30kw + 3.7kw + 1 kw

|

||||

|

Type

|

Single Worm Barrel

|

|

|

|

|

||||

|

Barrel

|

S.S. 304; seamless pipe

|

|

|

|

|

||||

|

Screws / Worms

|

Cast in Aluminium Silicon (LM6 grade)

|

|

|

|

|

||||

|

Pelletising Head

|

S.S. 304

|

|

|

|

|

||||

|

Nose Cone

|

S.S. 304

|

|

|

|

|

||||

|

Body

|

M.S.

|

|

|

|

|

||||

|

Hopper

|

S.S. 304

|

|

|

|

|

||||

|

Motor

|

Siemens make, 3 ph, 415V

(3ph, 220V motors available on order) |

|

|

|

|

||||

|

Gearbox

|

Premium make

|

|

|

|

|

||||

|

Bearings

|

SKF / ZKL

|

|

|

|

|

||||

Recommend Products

Double Arm Sigma Mixer

The Double Arm Sigma Mixer is used to mix perfume, colour, skin protecting agents and other additions with soap noodles. The Brit

Soap mixer is a twin paddle sigma blade mixer, cast from the highest quality stainless steel, which allows an efficient

amalgamation of all the ingredients present in the mixer.

Soap mixer is a twin paddle sigma blade mixer, cast from the highest quality stainless steel, which allows an efficient

amalgamation of all the ingredients present in the mixer.

Triple Roll Mill

A Triple Roll Mill is used for homogenization of the soap mixture. The high precision roll mills permit the soap to adjust the

structure of the crystalline soap particles so that the soap feels creamy and smooth to the human skin. The massively constructed

machines fitted with precision ground rollers are capable of making the soap perfectly homogeneous and completely incorporate the

colors, perfumes, additives and fillers into the soap mass.

structure of the crystalline soap particles so that the soap feels creamy and smooth to the human skin. The massively constructed

machines fitted with precision ground rollers are capable of making the soap perfectly homogeneous and completely incorporate the

colors, perfumes, additives and fillers into the soap mass.

Simplex Refiner Plodder

The simplex refining plodder receives soap noodles which have been fully mixed and amalgamated with colours, perfumes and other

additives directly from the bottom discharge door of the mixer, into the in-feed hopper of the plodder.

The plodder compresses, refines and filters the noodles through the filter screens and out through a Stainless Steel spaghetti

plate, hence offering a refined noodle for the triple roll mill to add further refining work.

The Brit Soap Simplex Plodder is a massively strong soap extruder driven by a reliable drive system giving the smoothest, most

powerful thrust to the rotating screw.

Brit Soap offers both Single Worm and Twin Worm Simplex Refiner Plodders.

additives directly from the bottom discharge door of the mixer, into the in-feed hopper of the plodder.

The plodder compresses, refines and filters the noodles through the filter screens and out through a Stainless Steel spaghetti

plate, hence offering a refined noodle for the triple roll mill to add further refining work.

The Brit Soap Simplex Plodder is a massively strong soap extruder driven by a reliable drive system giving the smoothest, most

powerful thrust to the rotating screw.

Brit Soap offers both Single Worm and Twin Worm Simplex Refiner Plodders.

About Us

Our Products & Services Offered

Our Presence

Contact Us

Hot Searches