- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

Injection Mold/Molding Service 0401

-

Keyword:

-

Plastic Injection Mold

-

Description:

-

Custom Plastic Injection Molding Mold

-

Color:

-

Customized Colors

-

Mold Life:

-

50,000 to 1,000,000 shots

-

Mold Core:

-

45#, 50#, P20, H13, 718, 1.2344, 1.2738, NAK80, S136 etc

-

Mold Cavity:

-

Single or Multiply Cavities

-

Production Material:

-

PP,PC,PS,PA6,POM,PE,PU,PVC,ABS,PMMA etc

-

Surface Finishing:

-

Silk-screen/Plating/Painting/Coating etc

-

Service:

-

OEM ODM Customized

-

Packaging:

-

Polybag packing or packed according to customer requirement

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

Guangdong, China

-

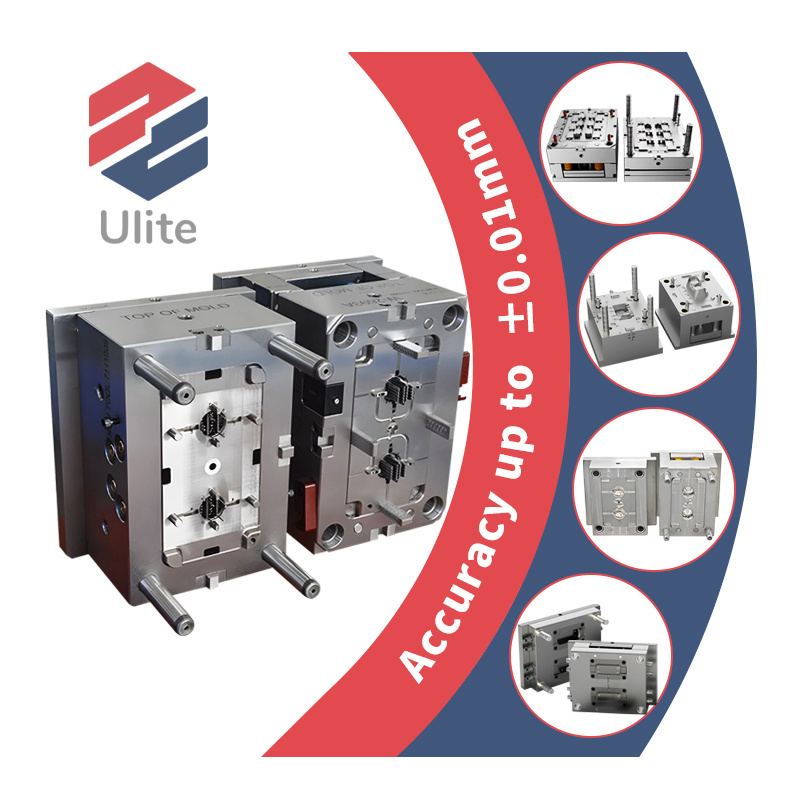

Brand Name:

-

Ulite

-

Model Number:

-

Injection Mold/Molding Service 0401

-

Keyword:

-

Plastic Injection Mold

-

Description:

-

Custom Plastic Injection Molding Mold

-

Color:

-

Customized Colors

-

Mold Life:

-

50,000 to 1,000,000 shots

-

Mold Core:

-

45#, 50#, P20, H13, 718, 1.2344, 1.2738, NAK80, S136 etc

-

Mold Cavity:

-

Single or Multiply Cavities

-

Production Material:

-

PP,PC,PS,PA6,POM,PE,PU,PVC,ABS,PMMA etc

-

Surface Finishing:

-

Silk-screen/Plating/Painting/Coating etc

-

Service:

-

OEM ODM Customized

-

Packaging:

-

Polybag packing or packed according to customer requirement

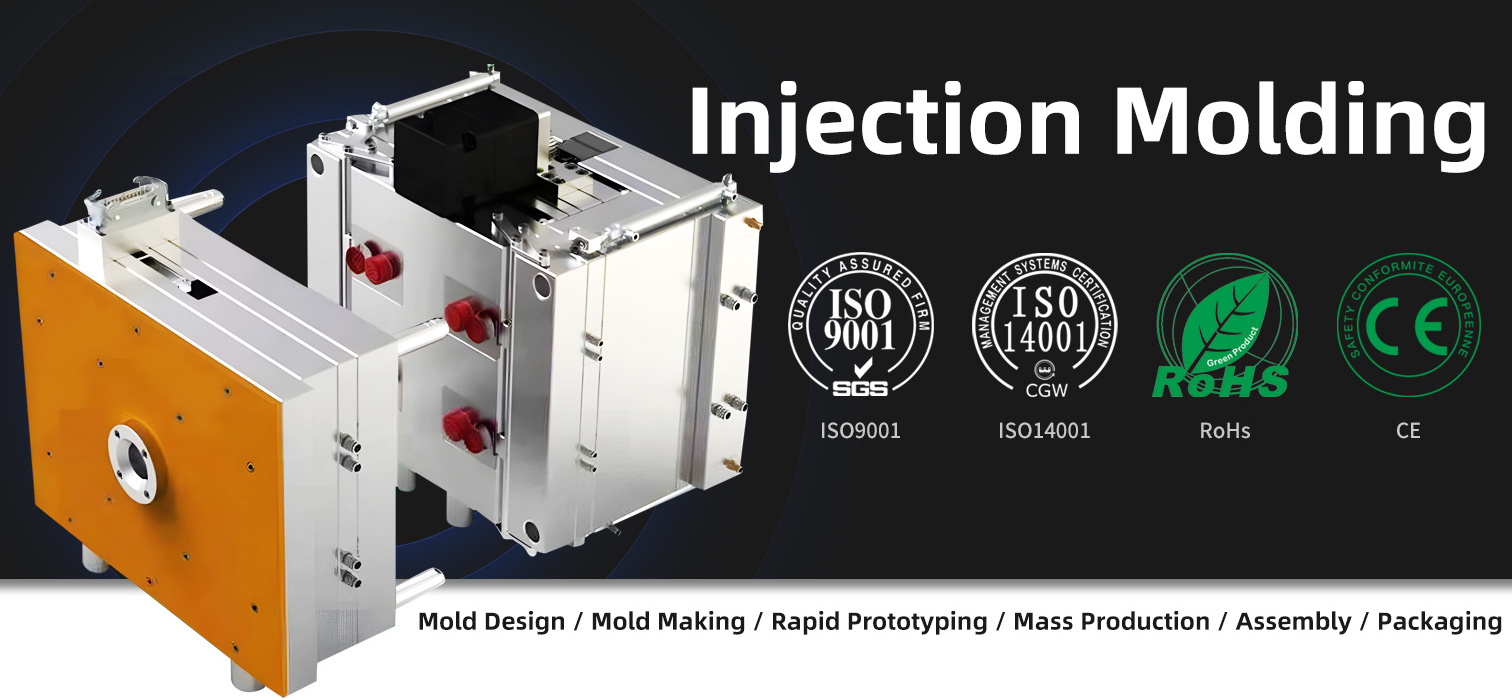

Our Service

One-stop Injection Mold Manufacturing and Plastic Parts Production Assembly

1. Prepare pictures or 3D drawings,

2. Materials for the required products,

3. Quantity of each order and estimate the annual demand.

☞ > Click on Send Inquiry or Chat Now

We will quickly provide you with professional advice to save mold costs and maintain high quality.

Mold Description

Mould Details -

|

Name

|

Plastic Injecition Mold

|

|

Mould core

|

P20,NAK80,SKD11,S316,S50C,S45C,718H,718 or customers' appointed

|

|

Mould base

|

LKM, HASCO, DME or upon customer's requirement

|

|

Type of plastic mold

|

3-plate mold,2-plate mold

|

|

Cavity

|

Single/Multi 1*1,1+1,1*2,1+1+1,etc

|

|

Mode Gate

|

Fan gate,Sub gate,Pin Point gate,Valve

|

|

Ejection system

|

Stripper plate,Lifter,Push Bar,Ejection Pin etc

|

|

Runner

|

Hot/cold type

|

|

Plastic material

|

HDPE, PP, nylon, PEEK, LDPE, ABS, styrene, acrylic, acetal, PE, PTFE, PEI, and PES

|

|

Mould life

|

300,000-1,000,000 shots

|

|

Lead time

|

15-35days after deposit received

|

|

Specification

|

Follow the 3D final drawing

|

|

Packaging details

|

covering with film for anti rust and packed with wooden Case

|

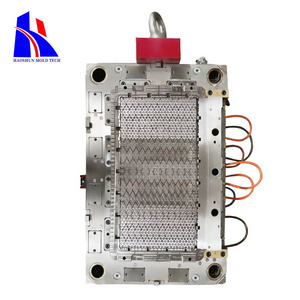

Parts Production Details -

|

Product Material

|

ABS,AS,PP,PPS,PC,PE,POM,PMMA,PS,HDPE,TPE,TPU etc

|

|

Surface finish

|

Polishing finish,Texture Finish,Glossy Finish,Painting,Slik print,Rubber Painting etc

|

|

MOQ

|

500 PCS

|

|

Packaging details

|

Carton box or wooden Case upon product weight and customer's requirements.

|

|

Shipping

|

By sea or by air as customer requirement

|

|

Export Country

|

Janpan,Europe,USA,Mexico,Australia,Middle East,Korea,Asia etc

|

|

Typical Used For

|

Housings, containers, caps, fittings,including as below

Power-tool housing, Disposable razors, Electrical Switches,Crates/Recycling boxes Automotive dash boards,Television Cabinets,Drug Inhalation Units,Automotive bumpers, Wheelie bins ,Syringes,Telephone handsets ,Washing-up bowls,DVDs, Bottle Lids/closures,Battery Casings |

|

Range of markets

|

industrial, consumer, food processing, aviation, seals/gaskets, lighting, packaging, filter,

healthcare, telecommunications, mechanical, water treatment, appliance, recreation, lawn and garden, educational, oil and gas, government, construction, plumbing, surveillance, pumps, marine, motors, gears, RFID tags, electronics, and fasteners. |

Plastic Applications

FAQ

Q1:

What is mould in plastic?

A1:

In the context of plastics manufacturing, a mold refers to a hollow form or cavity into which molten plastic material is injected, poured, or pressed to create a specific shape or configuration. Plastic molds are commonly used in processes such as injection molding, blow molding, compression molding, and thermoforming to produce a wide range of plastic parts, components, and products.

The best material for injection molds is steel. The choice of plastic mold steel grades is based on the type of mold material and geometry. Steel must meet certain specifications for the mold. The service life, ease of processing, and precision of the mold are significantly impacted by how well the steel is chosen.

Q3: Why is injection molding so important for today's products? A3.: Injection molding is renowned for its ability to produce parts with exceptional precision and consistent dimensions. This level ofaccuracy is essential in industries where even the slightest deviation can lead to significant issues, such as in aerospace or medical device manufacturing.

Q4. Can you 3D print injection molds? A4. Yes, we can 3D print injection molds, and it's becoming increasingly common in the manufacturing industry. This process, known as"rapid tooling" or "additive manufacturing for tooling," involves using 3D printing technology to create molds for injectionmolding processes.

While traditionally injection molds are machined from metals like steel or aluminum, 3D printing offers several advantages such as faster production times, lower costs for small production runs, and the ability to create complex geometries that might be

challenging or impossible with traditional machining methods.

However, there are some limitations to consider, such as material selection (3D printed molds may not be as durable as metal molds for high-volume production), surface finish quality, and dimensional accuracy. Additionally, not all 3D printing technologies are suitable for producing injection molds, so it's essential to choose the right printing method and material for the specific application.

Q5. How do injection molds work? A5. The injection moulding process involves heating & injecting plastic material under pressure into a closed metal mould tool. The molten plastic cools & hardens into the shape inside the mould tool, which then opens to allow the mouldings to be ejected or removed for inspection, delivery or secondary operations.

Q6: Why plastic mold is expensive? A6: Designing, creating and assembling injection moulds is a labour-intensive and complex process that takes time and skill to do correctly. Injection mould builders and designers are highly trained specialists that don't come cheap. If you cheap out on this, you might have to pay for the costs later on.

Hot Searches