- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Hebei Zetian Chemical

-

Model Number:

-

9183

-

Type:

-

powder

-

Product name:

-

Phenolic resin for refractory

-

Keywords:

-

phenolic resin

-

Material:

-

phenol

-

Application:

-

modified resin, coating and dry material

-

Residual carbon /850℃ (%):

-

Residual carbon /850℃ (%)40-50

-

Water content (%):

-

≤1

-

Free phenol (%):

-

≤4.0

-

Softening point (℃):

-

95-110

-

Appearance:

-

yellow to brown red powder

-

Grade:

-

9183

Quick Details

-

CAS No.:

-

9003-35-4

-

Other Names:

-

Bakelite powder

-

MF:

-

[C8H8O2]n

-

EINECS No.:

-

210-898-8

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Hebei Zetian Chemical

-

Model Number:

-

9183

-

Type:

-

powder

-

Product name:

-

Phenolic resin for refractory

-

Keywords:

-

phenolic resin

-

Material:

-

phenol

-

Application:

-

modified resin, coating and dry material

-

Residual carbon /850℃ (%):

-

Residual carbon /850℃ (%)40-50

-

Water content (%):

-

≤1

-

Free phenol (%):

-

≤4.0

-

Softening point (℃):

-

95-110

-

Appearance:

-

yellow to brown red powder

-

Grade:

-

9183

This series can be divided into two series, thermoplastic and thermosetting, h a ve the characteristics of high temperature resistance , high intensity etc., which can be used in the production of improved resin, bulk refractory material, such as: coating and dry material etc; the extender to improve the property of liquid resin, be used in the plug, stopper, water gap, magnesia carbon brick , the approval product : a lumina-magnesia-carbon products , slide gates brick etc, in order to improve the demanded wet strength.

PF9180 series technical data: use for refractory

|

Grade |

Appearance |

Softening point(℃)(International standard) |

P ellet flow/125℃(mm) |

Cure/150℃(s) |

Application/Characteristic |

|

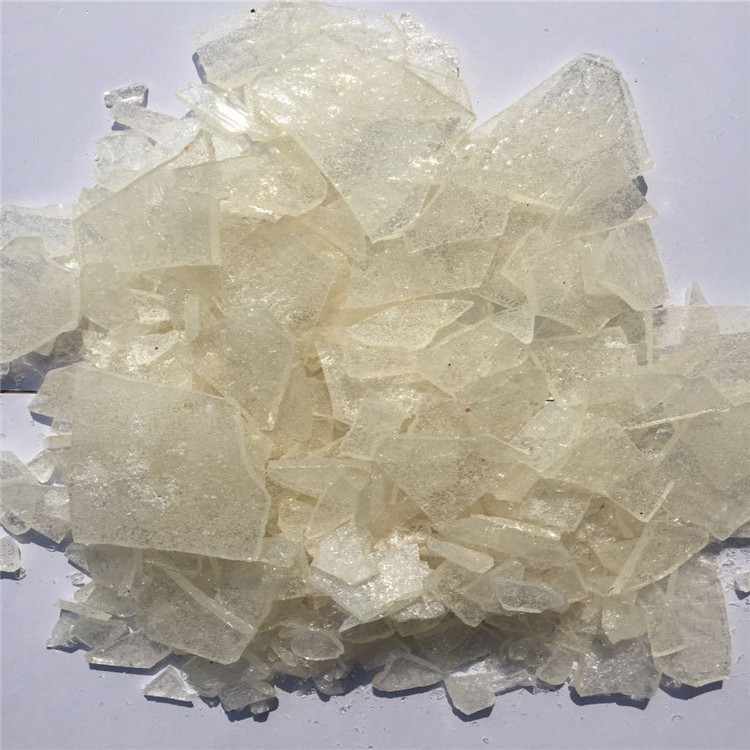

2123D1 |

Light yellow flakes or white flakes |

85-95 |

80-110 |

40-70 |

Common |

|

2123D2 |

95-105 |

70-100 |

40-60 |

||

|

2123D3 |

85-100 |

60-100 |

40-60 |

High intensity |

|

|

2123D4 |

90-100 |

60-90 |

3 0-50 |

High ortho, High intensity |

|

|

2123D5 |

Brown red sheet |

90-102 |

60-90 |

50-70 |

Common |

|

Grade |

Appearance |

Softening point (℃) |

Free phenol (%) |

Water content (%) |

Residual carbon /850℃ (%) |

Application/ Characteristic |

|

9181 |

White to Light yellow powder

|

108-114 |

2.5-4.0 |

≤1 |

53-58 |

coating and dry material |

|

9182 |

108-114 |

≤4.0 |

≤1 |

≥51 |

coating and dry material |

|

|

yellow to brown red powder |

95-110 |

≤4.0 |

≤1 |

40-50 |

modified resin, coating and dry material |

|

|

9184 |

White to Light yellow powder |

108-114 |

1.5-3.5 |

≤1 |

48-56 |

modified resin, dry material |

|

9185 |

98-105 |

≤4.5 |

≤1 |

37-42 |

plug, stopper rod ,water gap , dry material , t hermoplastic |

|

|

9186 |

103-109 |

3-4.5 |

≤1 |

37-42 |

plug, stopper rod ,water gap, T hermoplastic |

|

|

9187 |

108-114 |

≤4.0 |

≤1 |

≥37 |

coating and dry material T hermoplastic |

|

|

9188 |

108-114 |

2.5-4.5 |

≤1 |

≥40 |

coating and dry material, T hermoplastic |

|

|

9180P 1 |

Light yellow flakes |

101-120 |

3-4.5 |

≤1 |

——— |

T hermoplastic |

|

9182-1 |

White to Light yellow powder |

105-113 |

2-4 |

≤1 |

≥53 |

high intensity dry material |

Packing and storage:

Powder: 20 kg or 25 kg/bag, blocks , flakes: 25 kg/bag. Packed in woven bag, lined with plastic liner, or in kraft paper bag, lined with plastic liner. Resin should be stored in a cool, dry and well ventilated place far away from heat source to avoid moisture and caking. The storage life is 4-6 months below 20 ℃. Its color will become dark with the storage time, which will do no influence on the resin grade.