- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

250

-

Voltage:

-

220V, 50HZ, 1PH

-

Place of Origin:

-

China

-

Dimension(L*W*H):

-

3200*800*1350mm

-

Product name:

-

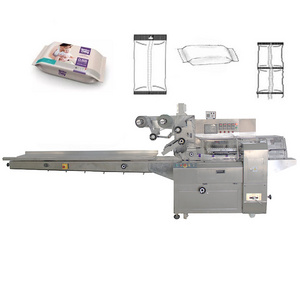

Pillow Packing Machine

-

Bag type:

-

Back Sealing

-

Main Function:

-

Packing Sealing Wrapping Packaging

-

Keyword:

-

Horizontal Flow Packing Machine

-

Usage:

-

Food Snack

-

After-sales Service Provided:

-

Online Support

-

Packing speed:

-

40-230 Bags/min

-

Machine type:

-

Auto Packing Machine

Quick Details

-

Function:

-

Wrapping, Sealing

-

Packaging Type:

-

Bags, Film

-

Packaging Material:

-

Plastic

-

Weight (KG):

-

250

-

Voltage:

-

220V, 50HZ, 1PH

-

Place of Origin:

-

China

-

Dimension(L*W*H):

-

3200*800*1350mm

-

Product name:

-

Pillow Packing Machine

-

Bag type:

-

Back Sealing

-

Main Function:

-

Packing Sealing Wrapping Packaging

-

Keyword:

-

Horizontal Flow Packing Machine

-

Usage:

-

Food Snack

-

After-sales Service Provided:

-

Online Support

-

Packing speed:

-

40-230 Bags/min

-

Machine type:

-

Auto Packing Machine

Product Description

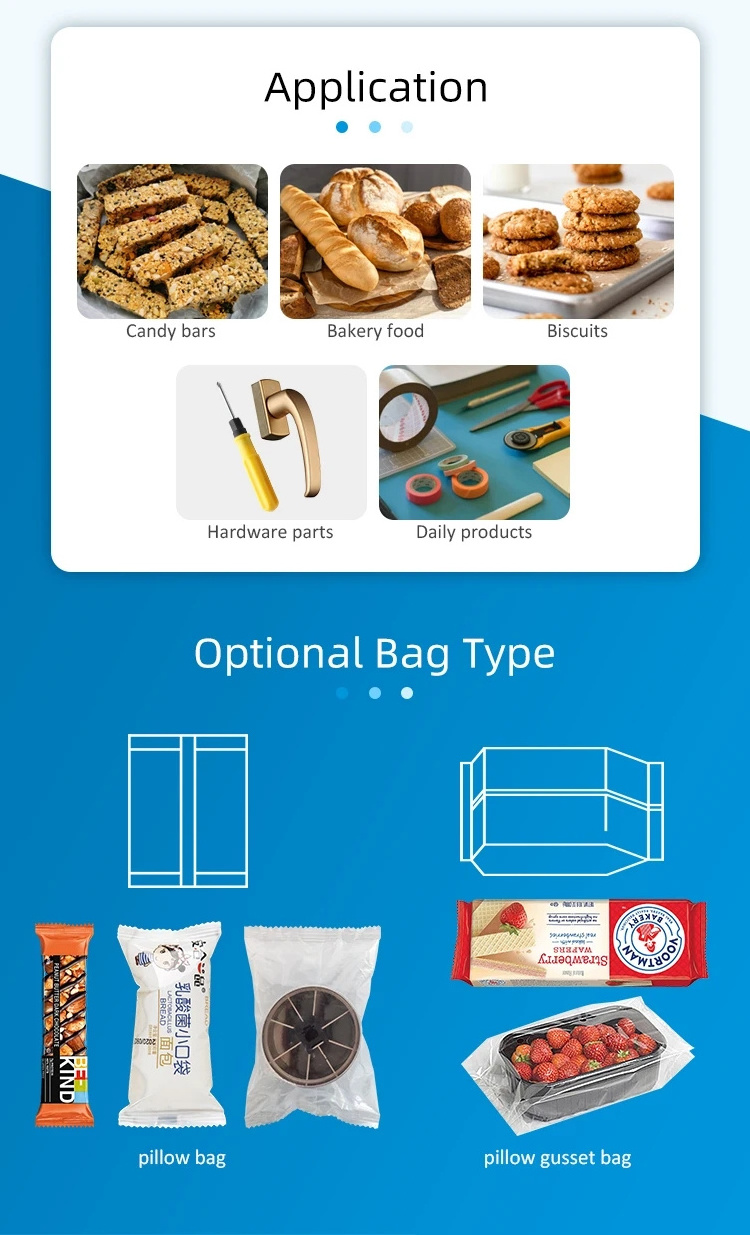

Application:

horizontal flow packing machine is suitable for different kinds of product packing into roll film bags. Such as candy, chocolate, protein bars, bakery food of cake, biscuit, bread, instant noodle, leafy vegetables, fruit and non-food products like hardware parts, daily supplies, hotel supplies, medical products, ect.

horizontal flow packing machine is suitable for different kinds of product packing into roll film bags. Such as candy, chocolate, protein bars, bakery food of cake, biscuit, bread, instant noodle, leafy vegetables, fruit and non-food products like hardware parts, daily supplies, hotel supplies, medical products, ect.

|

Model

|

SP-250XD

|

SP-350XD

|

SP-450XD

|

|

|

|

Packing speed

|

35-220bags/min

|

35-180bags/min

|

30-120bags/min

|

|

|

|

Bag size

|

double low cutter L60-190,W30-110,H5-50mm, double high cutter L90-220,W30-110,H5-60mm, Single high cutter L150-330,W30-110,H5-60mm

|

double low cutter L60-190,W30-160,H5-50mm, double high cutter L90-220,W30-160,H5-60mm, Single high cutter L150-330,W30-160,H5-60mm

|

L150-400,W50-200,H10-70mm

|

|

|

|

Film width

|

90-250mm

|

90-350mm

|

100-450mm

|

|

|

|

Power supply

|

1P/220V/50HZ, 2.4KW

|

1P/220V/50HZ, 2.5KW

|

1P/220V/50HZ, 2.8KW

|

|

|

|

Overall dimension

|

L3800*W850*H1500mm

|

L3800*W950*H1500mm

|

L4000*W1000*H1600mm

|

|

|

|

Net weight

|

400kg

|

500kg

|

600kg

|

|

|

Details Images

Main Advantage

1).Adopt the famous brand PLC intelligent controller and inverter, machine quality is more trustworthy.

2).7 inch famous brand touch screen, the system is more intelligent and easy to operate.

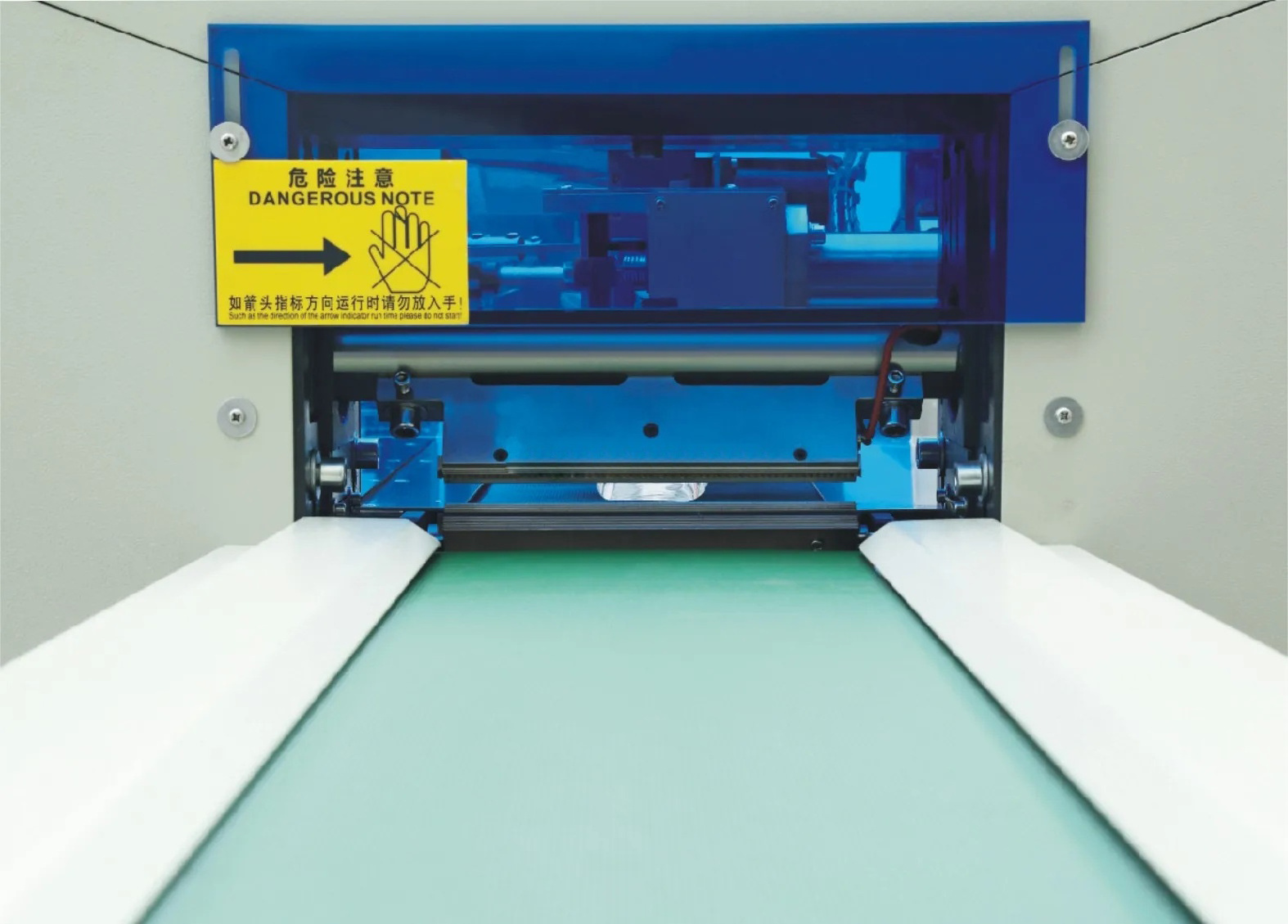

3).Independent temperature control system, the temperature error is within ± 1°C

4).Photocell sensor, automatically compensate the length deviation of the film.

5).The interface of the system is simple and easy to understand, and the parameter setting is easy and simple.

6).Self diagnosis fault, safe operation, protect equipment.

7).Flexible operation, high applicability, can be packed with a variety of materials, machine for multi-purpose.

8).Automatically complete feeding, bag making, sealing and date printing function to realize industrialized rapid packaging.

9).lt has high compatibility and can be matched with diversified equipment to meet diversified production requirements, such as punching, bagging, exhaust, aeration,OR code printing, etc.

10).The software operating system is stable. It also can customize the display of personalized logo on the touch screen.

Hot Searches