- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HX

-

Voltage:

-

380V/50HZ 3Phase

-

Power:

-

4kw

-

Dimension(L*W*H):

-

5.8*0.8*1.2m

-

Weight:

-

4500 kg

-

Product name:

-

metal stud and track roll forming machine

-

Raw material:

-

PPGI PPGL GI GL

-

Roller material:

-

Cr12

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Color:

-

Customised

-

Material thickness:

-

0.3mm-0.8mm

-

Cutting type:

-

Hydraulic Guide Pillar Cutting

-

Main frame:

-

400H Steel

-

Main Motor Power:

-

4kw

-

Motor brand:

-

Siemens

Quick Details

-

Marketing Type:

-

New Product 2024

-

Work Pressure:

-

16

-

Production Capacity:

-

16pa

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

HX

-

Voltage:

-

380V/50HZ 3Phase

-

Power:

-

4kw

-

Dimension(L*W*H):

-

5.8*0.8*1.2m

-

Weight:

-

4500 kg

-

Product name:

-

metal stud and track roll forming machine

-

Raw material:

-

PPGI PPGL GI GL

-

Roller material:

-

Cr12

-

Shaft material:

-

45# Steel Outer Diameter: 70mm

-

Color:

-

Customised

-

Material thickness:

-

0.3mm-0.8mm

-

Cutting type:

-

Hydraulic Guide Pillar Cutting

-

Main frame:

-

400H Steel

-

Main Motor Power:

-

4kw

-

Motor brand:

-

Siemens

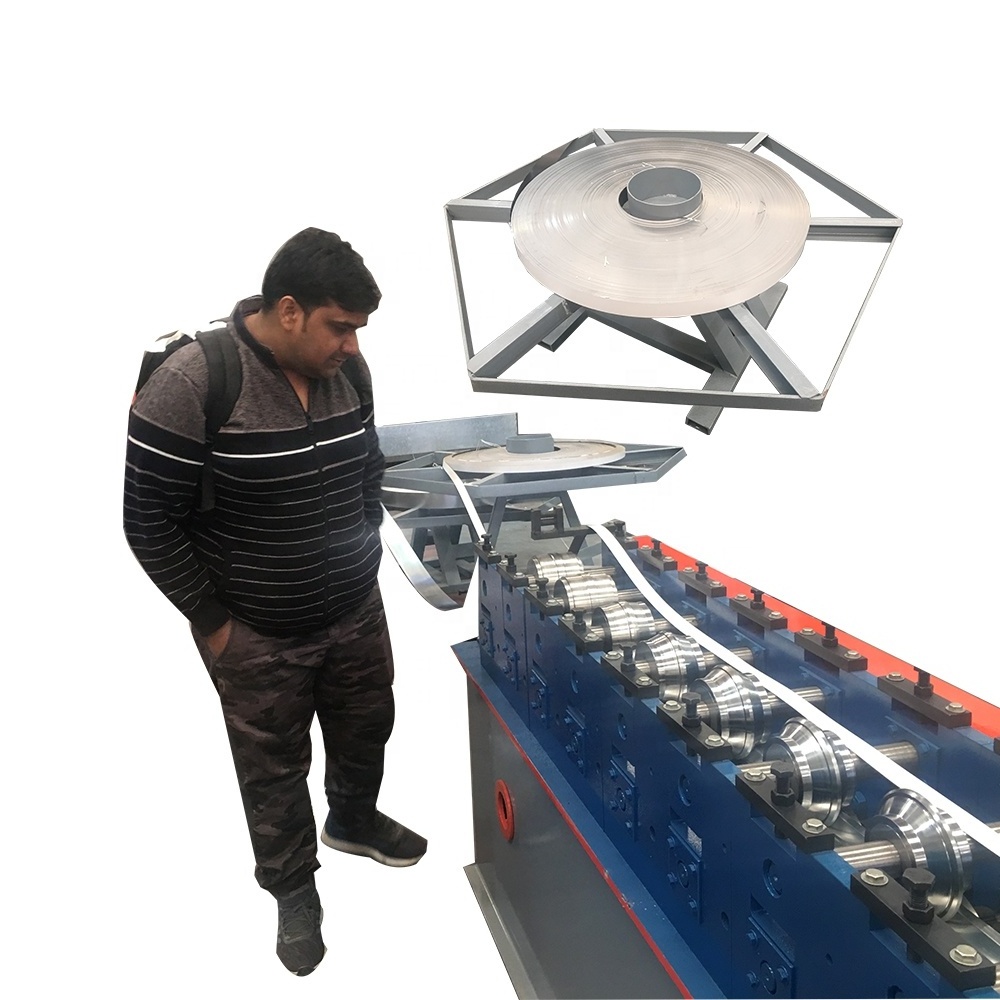

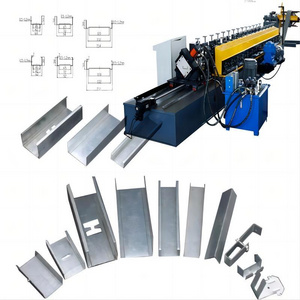

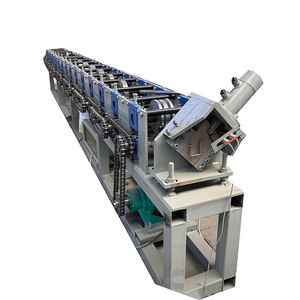

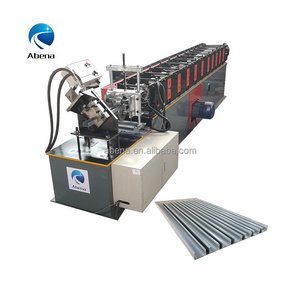

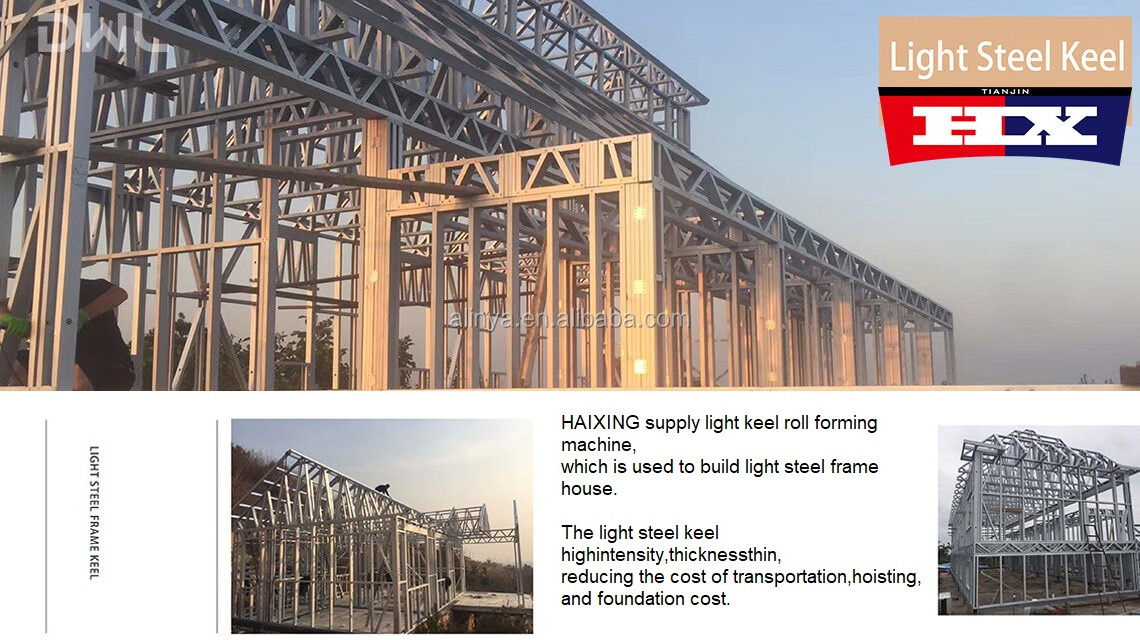

Light Gauge Steel Framing Machines Specifications

*Light Gauge Steel framing machine is a cold rolling machine of Steel Frame which can realize the continuous automatic production.The light frame roll forming line includes hydraulic expansion decoiler, leveling equipment, roll forming system, punching equipment, cutting equipment, hydraulic station, electric controlling system and supporter for purlin. The light guage steel frame roll forming line adopts PLC control, AC frequency and speed adjusting technology to realize continuous production automatically.

*The cold rolling machine of Steel Frame is energy-saving and high-effective to produce equipment for steel structure.

*The cold rolling machine of Steel Frame is energy-saving and high-effective to produce equipment for steel structure.

|

|

Machine Parameters

|

|

product name

|

metal stud and track roll forming machine

|

|

Suitable to process

|

Color steel plate

|

|

Control System

|

PLC Colored Touch Screen

|

|

Rollers

|

10 stands

|

|

Shaft Diameter

|

60mm

|

|

Thickness of the plate

|

0.3-1.2mm

|

|

Hydraulic Pressure

|

10-12MPa

|

|

Roller Standard

|

45#steel with chrome coating heat treatment

|

|

Cr-Plating Size

|

0.05mm

|

|

Cutter Standard

|

Cr12

|

|

Power

|

5.5Kw

|

|

Voltage

|

380V 50Hz 3phases

|

|

Overall Size

|

3.8 Tons

|

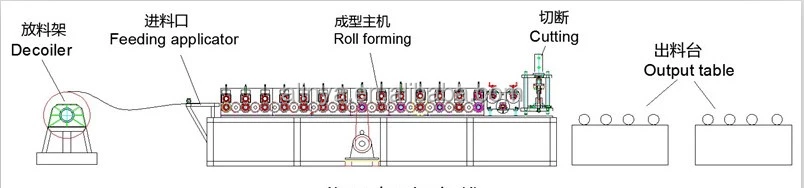

Working Flow:

Rollforming process:uncoiler

→

rollforming

→

forming step effect

→

cut to length.

Name:Manual decoiler

Manual decoiler Coils inner diameter 450-550(mm) Coils outside diameter 1500(mm) Max can put max 700kgs

High-level automatic control PLC system

Brand:Delta PLC

system: Chinese/ English/Russian/ Spanish

PLC:The PLC control system introduces computer technology, automatic control and other technologies based on traditional controllers.

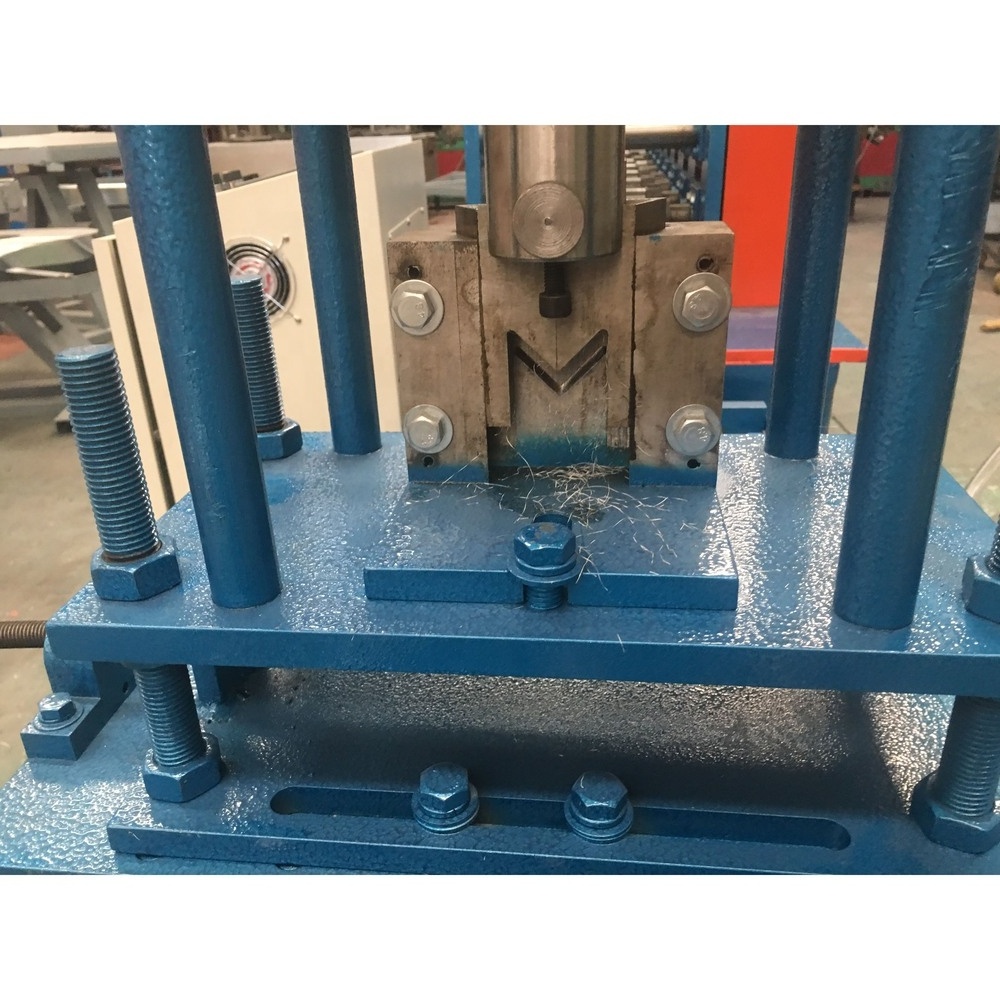

Name:Cutting head

Blade material: Cr12MOV, forged by heat treatment.

The cutting head uses an High quality electro-hydraulic cutting system and automatic positioning function

Because the cutting method is stable, metal plate cross section is neat.

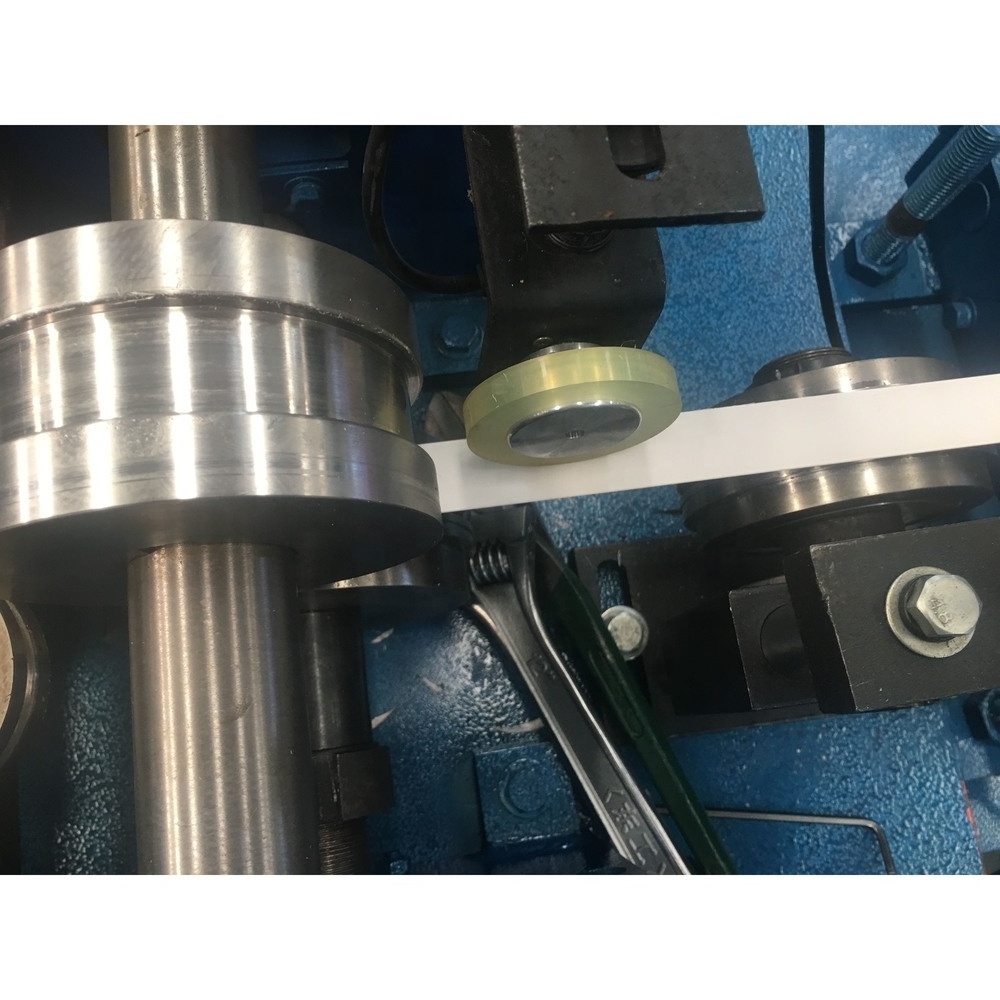

Name: Main rollers

Roller materials: Cr12, Quenching, hardness HRC56-82º

Roller numbers:16 rows

Axis number :32 Pieces

Transmission: gear drive

Side wall: Thickness 25mm

Material of the shaft :45# forged steel

Main machine frame flat: Thickness 16mm ,precision finish

Feed positioning: manual positioning, flexible at both ends

Cutting :Hydraulic cutting

Mold materials :SKD11 with hardness quenched treatment 56-58º

International brand accessories

When the machine has parts aging due to long service , don't worry about it. All we used are international brand accessories, you

could buy the same one locally and quikly!!!

Framing Metal Stud And Track Roll Forming Machine Advantage:

***

Fully Automatic Control System with PLC.

***

Easy operation: Key in the length and quantity on the control panel.

*** Two years warranty for free, and beyond two years if any part broken, tell us and pay us we delievery any part u need. And support technical skills for machine for whole life.

*** Two years warranty for free, and beyond two years if any part broken, tell us and pay us we delievery any part u need. And support technical skills for machine for whole life.

About us

Tianjin Haixing is a professional cold roll forming machine manufacturer, We have been focusing on this field for 22 years.

Our equipment includes roof roll forming machine, floor deck roll forming machine, automatic decoler, shutter door roll forming machine, light keel roll forming machine, purlin machine, leveling a

nd slitting machine, and

other related construction equipment.

Haixing has employed a team of engineers for more than 20 years. At the same time,

our machines use branded electrical components, raw materials from branded steel factories, strict process control, two-year warranty, installation and training services.

We have provided services to customers in 85 countries/regions and provide solutions based on your local hot-selling models

, such as 65 countries in Germany, the United States, Mexico, Chile, Bolivia, Italy, Australia, Kuwait, Saudi Arabia, South Korea, Japan, South Africa, Kenya and other different regions. We have extensive experience in the needs of different countries, such as profile, thickness range, use, installation, etc.

Company tenet: technological innovation, customer center, win-win situation. Thank you for your trust and choice, we will provide you with the best service support and help you achieve greater success.

Looking forward to more cooperation with new and old friends from all over the world.

Packing & Delivery

FAQ

Q: Are you a trading company or a factory?

A: We are factory with professional production team and service consciousness just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style panel profile?

A: Not complete. Suitable for wider and double layer manufacturing machines. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the machine can be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing and packaging on the roll surface and shaft.

Q: What can you do if the machine broken?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation and we provide technical support for the entire life cycle of the device.

Q: What is your strength compared to other suppliers?

A: We will give you the best service. We will provide you with good advice that exceeds your requirements. These lines are easy to install and have low maintenance requirements.

Q: Can we become your agent abroad?

A: Of course, if you have a business in the rolling forming line, we will welcome a lot of cooperation.

A: We are factory with professional production team and service consciousness just for exporting various types of cold roll forming machines.

Q: Can a machine produce only one style panel profile?

A: Not complete. Suitable for wider and double layer manufacturing machines. It can produce more than 3 panels.

Q: How long does it take to manufacture the machine?

A: In general, the machine can be completed in 20 to 45 business days. But if you need machines urgently, we can save you time.

Q: Is there quality control when producing the production line?

A: Yes, we have a team that is responsible for quality control, including the laying of raw materials, processing rolls and other parts, processing, assembly, testing and packaging on the roll surface and shaft.

Q: What can you do if the machine broken?

A: Our machine is warranted for 24 months. If the damaged part cannot be repaired, we can send a new part to replace the damaged part, but you will need to pay the courier fee yourself. If the warranty period is exceeded, we can resolve the issue through negotiation and we provide technical support for the entire life cycle of the device.

Q: What is your strength compared to other suppliers?

A: We will give you the best service. We will provide you with good advice that exceeds your requirements. These lines are easy to install and have low maintenance requirements.

Q: Can we become your agent abroad?

A: Of course, if you have a business in the rolling forming line, we will welcome a lot of cooperation.

Engineering case

1.The ridge tiles are rich in color, classical and elegant, and are used in glazed tiles to add a finishing touch to modern

architecture.

2.It has light weight, high strength, good waterproof and convenient installation. Special materials or sheet thickness, the

machine can be customized according to customer requirements.Can be widely used in villa roofs, urban flat slopes, tourist scenic

areas and so on.

architecture.

2.It has light weight, high strength, good waterproof and convenient installation. Special materials or sheet thickness, the

machine can be customized according to customer requirements.Can be widely used in villa roofs, urban flat slopes, tourist scenic

areas and so on.

Hot Searches